How Integrative IT Adds Value in Manufacturing

Digital transformation is not an end in itself. In the Industrial IoT (IIoT) era, digital transformation in factories aims to ensure business continuity and secure competitiveness. The main goals are sustainably higher efficiency in production and planning as well as sustainable profitability. 2020 has been a year like no other with shutdowns, stay-at-home regulations, and a steep slump in sales, and manufacturing companies are feeling the pressure. Managers have to tackle two challenges: cut down costs in the short term and make sure that companies stay profitable and competitive in the long term.

Digital transformation is managers’ best shot at successfully tackling these challenges. It is therefore more crucial than ever before to leverage the technological possibilities of Industrial IoT. Connecting products, machines, systems, processes, and factories is the foundation for future-proof manufacturing and the factory of the future.

The focus on digital in the 21st century has shown that how factories operate can add significant value to overall operations. The McKinsey study ‘Industry 4.0—Capturing Value at Scale in Discrete Manufacturing’ has identified three key principles guiding the capture of value through Industry 4.0 at scale: focus on adding value, focus on people, establish a new integrative infrastructure.

The third principle is prerequisite for the success of the other two, as companies are only really able to focus on adding value if investments in existing IT systems remain secure while new necessary systems can still be integrated. Furthermore, only an integrative IT solution guarantees that companies are equipping their teams with state-of-the-art tools to enable them to act autonomously.

Companies can only be truly successful if they focus on people instead of tools. Employees need to be able to fulfill their value-adding tasks autonomously and responsibly. Companies therefore need to focus their Industry 4.0 transformations on capability building and pursue them as strategic organizational endeavors. A digital transformation is about factory work 4.0, enabling new and motivating manufacturing experience.

Software construction like urban planning

Industry 4.0 is a complex topic, which is why there are so-called reference architectures. The main goal is to make the planning of processes and finances as precise as possible and to align it as closely as possible with reality. The reality on the store floor must be objectively and cleanly recorded and made accessible to everyone.

Like urban planning with sewers, streets and buildings, modern factory IT architecture is about different layers that build on each other, complement each other, depend on each other.

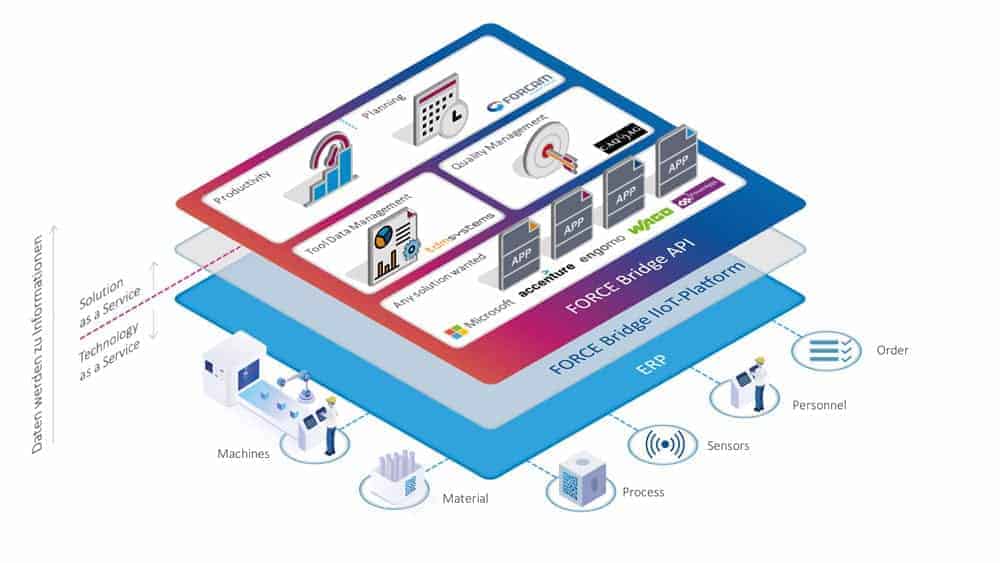

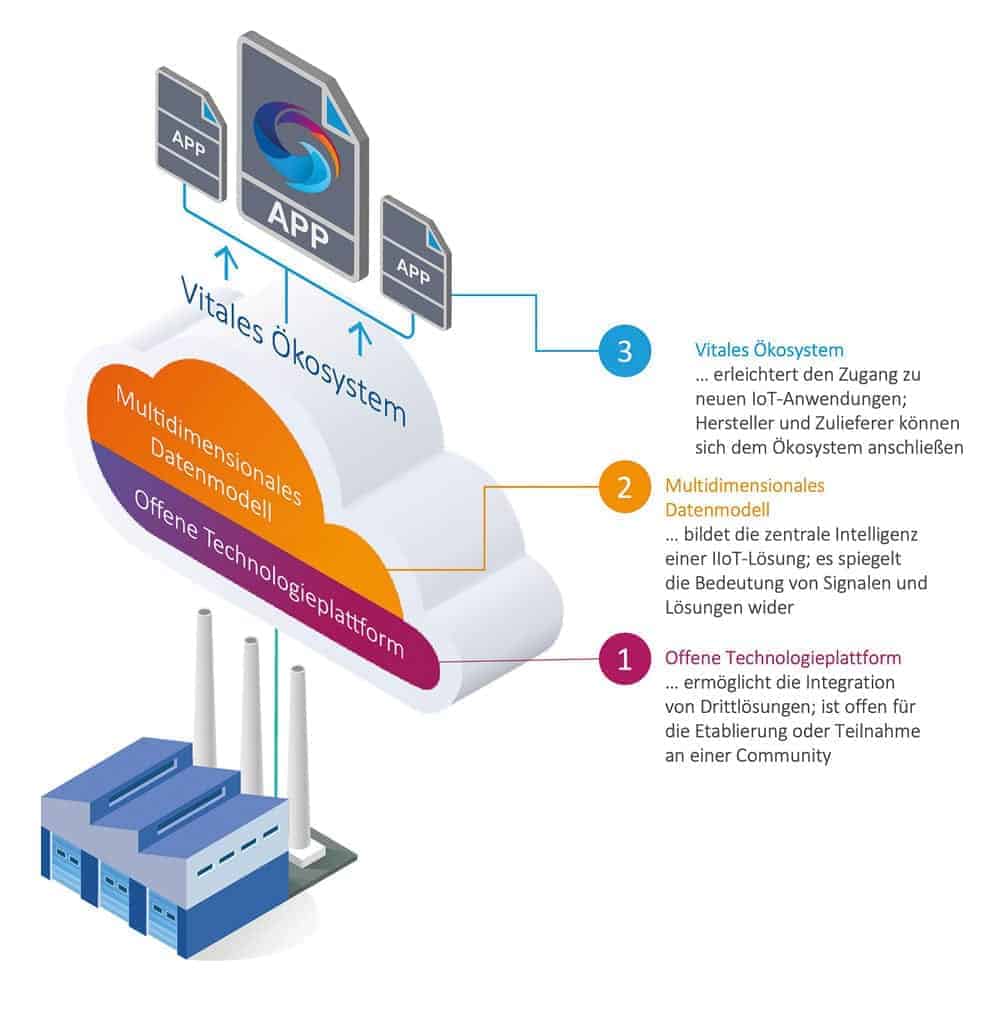

The architecture of the Forcam IIoT platform solution follows the described principle of "enabling innovation, protecting investments". Conceptually, the solution consists of three levels.

- Open technology platform: Transparency requires connectivity: The first layer of our factory IT architecture is an open technology platform that enables comprehensive horizontal and vertical connectivity. Here, reality is objectively captured digitally, i.e. the signals from machines, material, processes, sensors, personnel, production orders.

This real data is collected and standardized in real time at the edge, i.e. locally at the machines in the plants. They form the basis for the required transparency of all processes for all participants - on the store floor as well as on the pot floor.

Horizontal connectivity is followed by the important vertical networking into the pot floor: the production data model generated at the next architectural level is integrated with controlling, namely with the financial data model of the ERP systems such as SAP with the unit cost and overhead cost planning. - Digital twin through uniform production data model: The central semantic intelligence - the rule engine - works on the second level. It generates a multidimensional production data model: Here, data becomes information, Big Data becomes Smart Data.

From untold data such as energy values, process and machine data, labor time and traceability data, and so on, the production data model provides the digital twin of each product throughout its lifecycle.

This digital twin in combination with new architectures, with new cloud systems and new applications can result in new business models. Analytically, the universal production data model forms the "Singe Source of Truth" .

Production thus becomes part of an IT network and no longer forms a monolithic system. The center of this network is the dormant unified data lake. With the unified data lake, a company can open itself up to the innovative applications it needs for digital evolution. - Being smart means being open to ecosystems: Every manufacturing company has its own needs and requirements. Every company wants to be able to act quickly and flexibly.

Openness is therefore a basic requirement in the manufacturing world of the future. That is why the information in the third level of our solution is open to other applications through open web interfaces (Open API), in our solution the Force Bridge API.

Composition and collaboration

Like bridges, the information from the data lake is available via Open API to almost any desired real-time application - performance analyses, detailed planning (schedule and dispatch), traceability (track and trace), to name just a few.

Forcam's universal production data model can be opened up to information from third-party apps as well as cloud infrastructure providers - for example, Microsoft Azure's cognitive services for AI, the many market-renowned apps on the Microsoft Power Platform, or Microsoft BI services, business intelligence, for collaboration and composition.

Companies have the ability to use their production data lake to apply their own business semantics to many other desired business applications.

Adaptable IT platform technology makes manufacturing intelligent, and everyone benefits, right down to the workers. In this way, customer-specific user interfaces can be developed for the workforce, individual factory apps can be configured with start-up applications, or completely new proprietary and industry-specific solutions can be found.