Added value with classification

HAWE Hydraulik manufactures individual hydraulic parts and systems for the global market that perform critical functions in many applications such as aircraft, boats or vehicles. The products of the customers are diverse and demanding. The solutions must correspond in all markets. The resulting enormous variety of variants is absorbed with a consistent modular design.

Global classification: The family-owned company, headquartered in Munich, Germany, has subsidiaries in Europe, North America and Asia that form a worldwide network. The production plants in Germany supply customers around the globe. Depth of value added, efficient processes and consistent quality thinking ensure the reliability and robustness and service life of the products.

In preparation for further digitization projects, the company set itself the goal last year of maintaining all available material master data in a structured and classified form in the SAP ERP system used worldwide. After various attempts in individual areas, a generally applicable, consistent classification was now to be developed and implemented. Simus Systems was selected as the service partner for this. "After market research, demonstrations and reference visits, we determined that Simus' structured approach, software support and experience were the best fit for us," says project manager Korbinian Peters, Systems Engineer, who is implementing the project together with his colleague Christoph Römer. Both are in charge of the software for product development, the 3D CAD system Inventor and the associated solution for product data management.

Tools and methods

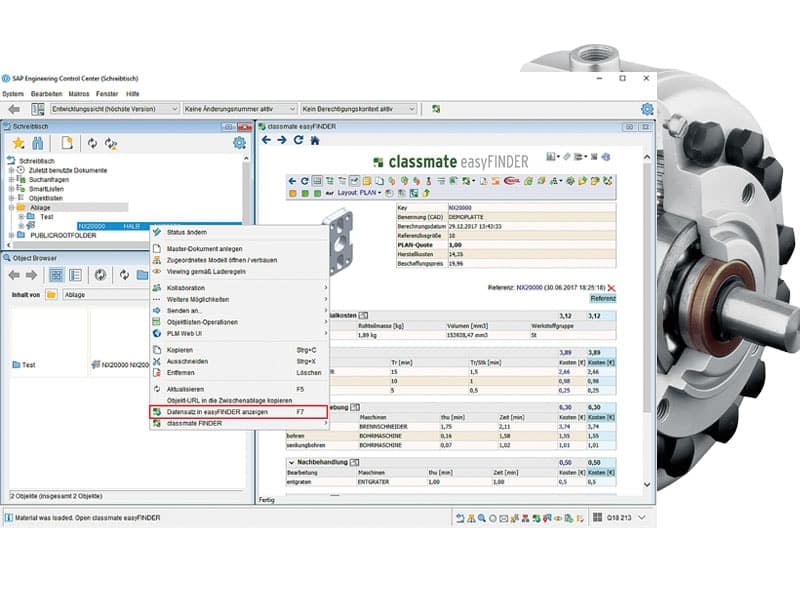

Simus develops software for the automatic classification of master data, which can also classify 3D CAD models geometrically and take their metadata into account. The Classmate solution facilitates classification tasks as well as migration projects. Other Simus modules unlock the benefits of meaningful, uniform, structured databases. These include the automatic creation of routings and their calculation based on CAD models, master data governance and automatic text generation based on characteristics. Equally well received by users is a clearly structured project methodology that Simus uses to shape collaboration.

Preliminary project shows potential

HAWE wanted to introduce a classification from a technical point of view. For this purpose, the material master was read out from SAP in the preliminary project. Around 60,000 materials from two material types were transferred into a functional classification. A standard classification was used for standard and purchased parts. In the course of the project, 45 percent of the material master could already be classified in a rudimentary way; for some classes, exemplary characteristic lists were defined. "The class structure brought in by Simus and the automatic processing of the data in Classmate also saved us a lot of time and effort later on"says Peters.

Simus was thus able to demonstrate the potential of the planned approach for the company. In workshops and discussions, the task was further elaborated, the internal and external efforts were defined, and an offer was prepared. In December 2020, HAWE commissioned a project to set up the classification with text standardization, duplicate analysis and SAP interface for transferring the new data to the ERP system.

The project began with a kick-off meeting to finalize the data to be considered, agree the schedule for six to nine months, and assemble the project team with permanent project managers on both sides. Then, several on-site workshops are typically held with the affected departments to agree on the classification hierarchy of standard and purchased part classes, condense about 1500 temporary classes, and specify subject characteristics for them. But because of the covid pandemic, the results were reviewed and refined in around 20 online workshops with the project managers and around eight to ten experts from the respective affected areas, such as electronics or machine elements. "The screen time of about two hours was at least as effective as the usual on-site workshops"says Korbinian Peters.

By means of pattern recognition of the existing short and basic data texts, many evaluations of the defined factual characteristics could be calculated. External data sources such as supplier catalogs in their various formats were also included. This resulted in a total of about 450 characteristics for the two material types.

In a subsequent phase of individual reviews, the material masters were to be further improved. For this purpose, Simus already provided a data table during the project phase. To make it easier for employees to confirm the results or add change requests, the Classmate Finder search engine was installed at the respective workstations. An associated review training course ensured a uniform, correct procedure.

New SAP material master data

In order to finally be able to use and maintain the finished material master data in the SAP system used by HAWE, a compliant structure master was developed that defines which structural elements are to be transferred to classes or characteristics. Recently, around 46,000 current and complete data records have now been successfully imported into the SAP test system. "Now it is becoming visible what treasures of data we have and what we can do with it"says a delighted Korbinian Peters. "We want to launch many projects on digitization topics on this basis." In addition, the company expects that thanks to the increased transparency and uniqueness, fewer duplicate data records and thus superfluous material masters will be created in the future.

The project was completed on schedule within the agreed budget and in the record time of around six months. "We have found Simus to be a very competent partner with good ideas", Korbinian Peters concludes. "We will keep their solutions in mind." Another benefit HAWE could derive from a standard set of rules for defining texts based on the classification features. For example, order texts for purchasing or the translations into different languages that are common in -international companies can be created automatically.

HAWE is a medium-sized, internationally active family-owned company with headquarters in Munich. 19 subsidiaries in Europe, North America and Asia form a worldwide sales, service and engineering network. The production plants in Germany supply customers around the globe. A high level of vertical integration, efficient processes and consistent quality thinking ensure the reliability, robustness and durability of the products. HAWE Hydraulik has the ambition to combine over 70 years of experience in hydraulics with the integration of new technologies to provide innovative solutions.