Ready, Set, Migrate to S/4HANA

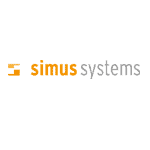

Simus systems supports companies with software and services to prepare a solid database that enables optimal use of the new ERP environment. With every migration, incomplete, outdated or inconsistent data not only jeopardizes the go-live, but also the long-term use of the new system environment. However, compared to other ERP systems and older SAP versions, this applies all the more to SAP S/4HANA.

Master data determines migration success

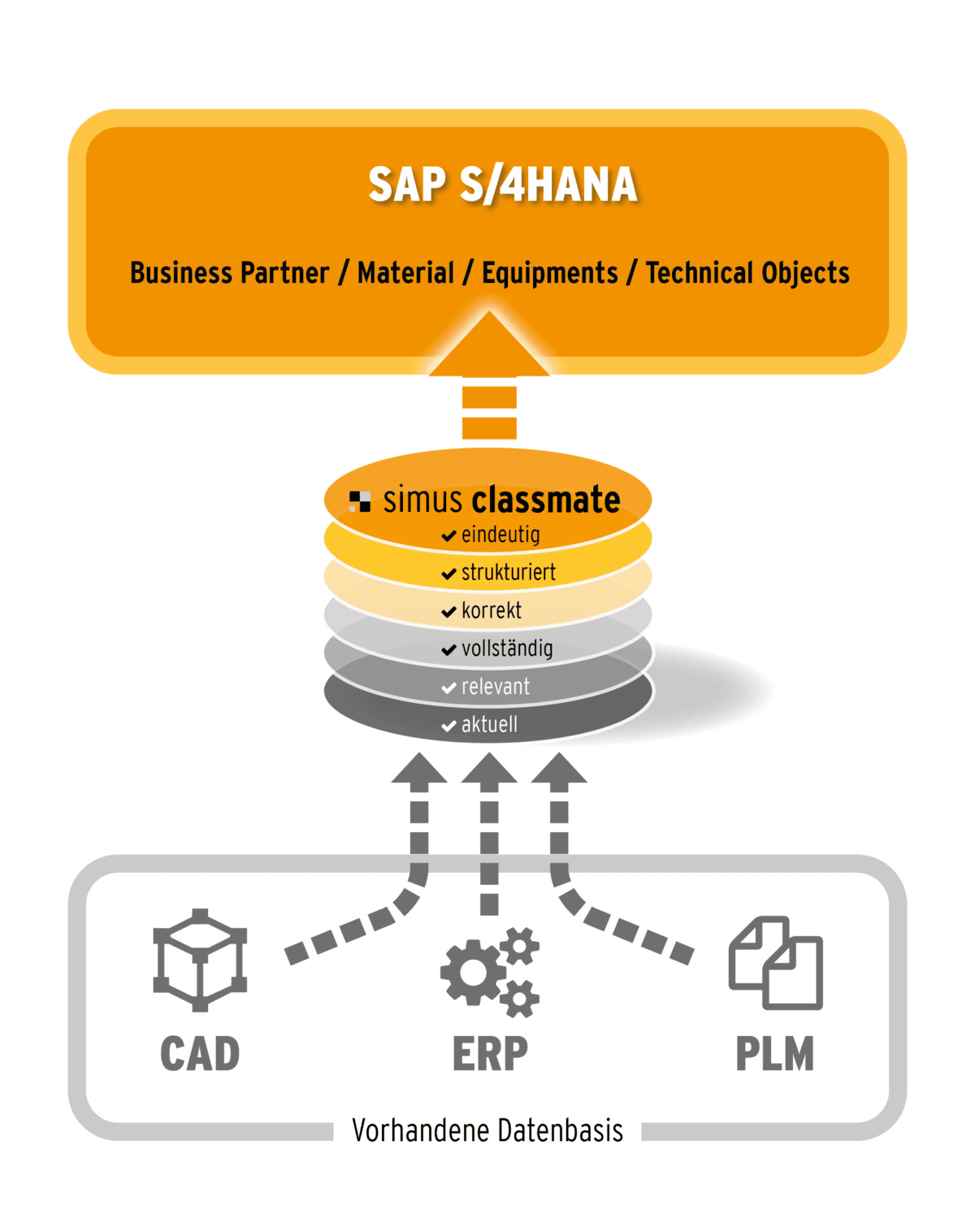

In SAP S/4HANA, master data is more closely integrated into processes, evaluations and user interfaces than ever before. The platform pursues the goal of a simplified, centralized data model that supports real-time processing, automation and analysis. This requires a particularly high level of data quality - especially for central master data objects such as business partners, materials and documents.

Some far-reaching structural changes introduced with S/4HANA reinforce this. For example, the Business Partner (BP) area was created as the sole source for customer and supplier master data in order to improve data integrity and eliminate redundancies. In other ERP systems, customers (debtors) and suppliers (creditors) are handled as separate master data. Before a migration, it is not sufficient to create these as SAP Business Partner groups. This is because roles such as customer, vendor, supplier, ordering party or ship-to party can still be flexibly assigned to an SAP Business Partner via groups and roles during the course of the business relationship.

IT managers with the structure and quality of the

master data.

What data is needed, how and where?

IT managers must therefore define early on in the migration strategy which data objects are to be transferred to the target system. This involves not only material masters and business partners, but also other technical objects such as equipment, parts lists or classifications. At the same time, the existing data should be analyzed according to quality criteria: Which fields are incomplete? Where are there duplicates or inconsistent values? Which data is outdated and can be archived?

Even at this early stage, it is advisable to bring an experienced service provider on board who understands the target structure in S/4HANA. For example, if SAP Business Partner replaces accounts receivable and accounts payable, this has an impact on roles, mandatory fields and processes. It saves a lot of time and effort if such effects are taken into account in advance. simus systems brings sophisticated methods, tools and experience to the table.

External support essential

The collaboration with simus systems begins with a preliminary project that creates clarity about the potential and the internal and external costs involved. To this end, a manageable amount of data is first provided by the customer and processed externally. Based on the results, the objectives for the actual project are defined in workshops and discussions. They begin with a functional reorganization of the master data and often include the classification of standard and purchased parts as well as the creation of additional, customer-specific functional classes that significantly increase the reuse rate of materials.

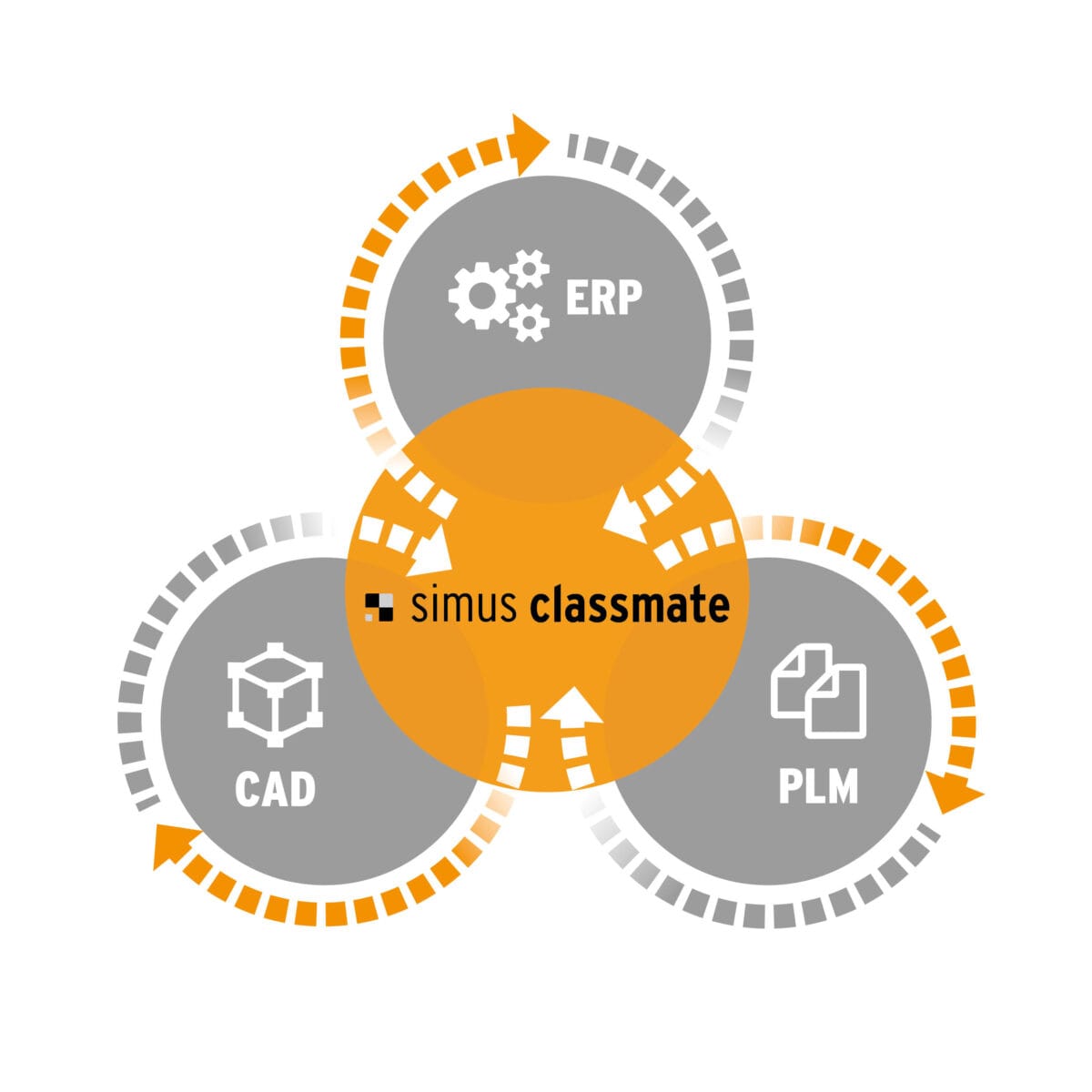

usual system landscape of industrial companies.

Change rules instead of editing data

At the start of the project, all relevant data is read from the relevant sources and processed. The data is sorted, enriched and stored in a results database according to initially neutral rules for preparation and optimization. The results can then be filtered and viewed using the classmate FINDER search engine to identify any errors, duplicates or inaccuracies. The results are refined in workshops or team conferences with the customer's relevant specialist departments. However, changes are not corrected via individual data records, but via formatting rules.

The data is automatically structured into the appropriate classes. This means that even large volumes of data can be processed within hours. Thanks to this method, up to 80 percent of the effort required for data processing is saved. The data, including the new structure, is then imported into the new system using a flexible interface from simus systems.

Sustainable assurance of data quality

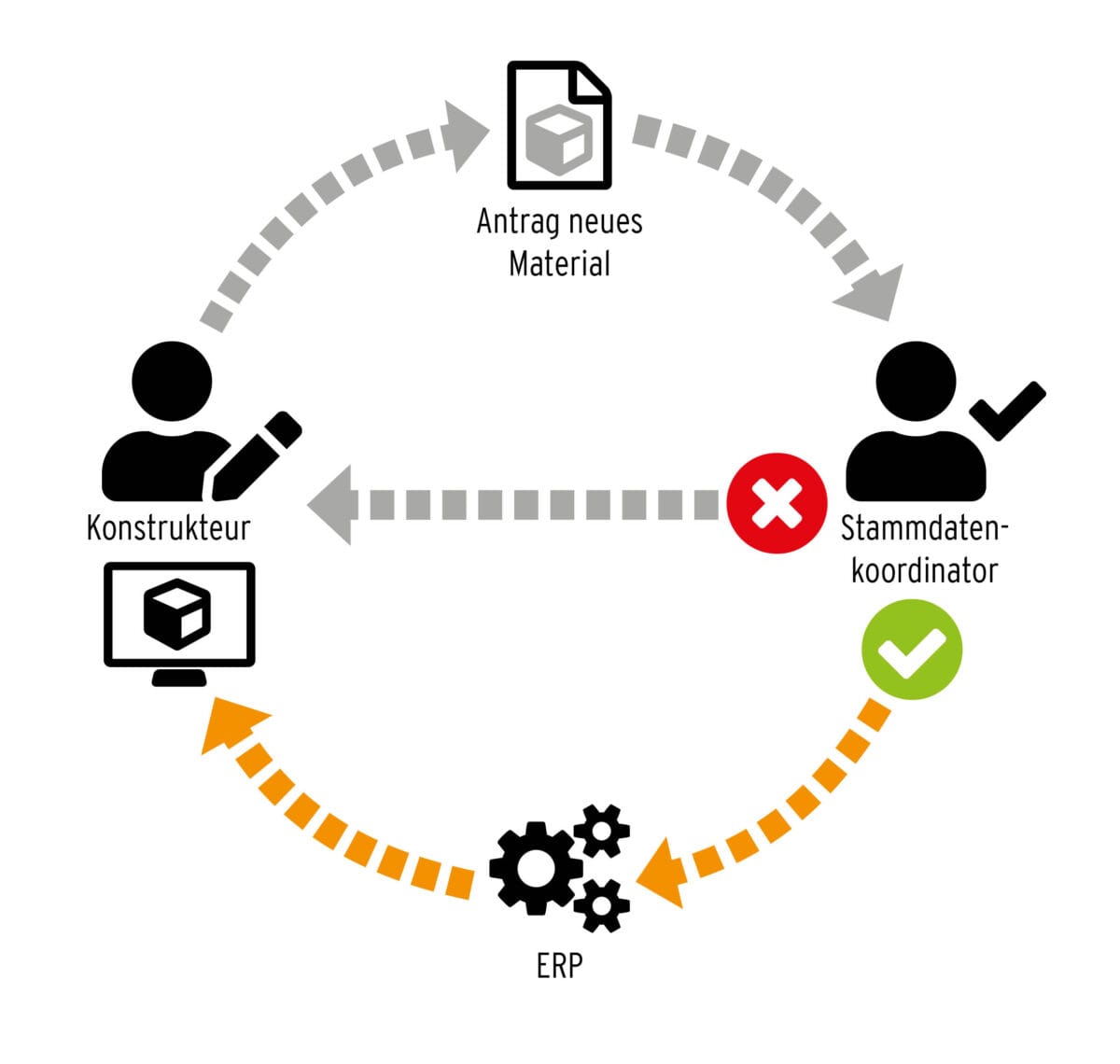

In order to maintain the quality of the master data once it has been achieved, classmate FINDER transfers the rules of master data governance into processes. For example, users can submit a material request if they cannot find a required part. A master data center reviews the material requests. Once a positive decision has been made, the new material is automatically created in SAP S4/HANA via the interface.

Cross-company care process

Data maintenance for business partners, equipment or material masters can also be automated across several departments in customizable processes. An authorization concept ensures security, intelligent default settings reduce effort and prevent incorrect entries. Intelligent support for routine tasks speeds up throughput times, while the database remains up-to-date and of high value.

High user-friendliness, low effort

Data preparation before a migration to SAP S4/HANA is a necessity. Subsequent data maintenance with simus classmate leads to greater user-friendliness, flexibility and transparency. Workflows can be defined and adapted more cost-effectively independently of SAP - without giving up the data sovereignty of the ERP system. But simus classmate brings further benefits. This includes the automatic creation and maintenance of material short texts and goods tariff numbers, for example, as well as the maintenance of purchasing info records together with the material. Even automatic translation routines of these texts into several target languages are easily implemented.

About simus systems

Founded in 2002 and based in Karlsruhe, simus systems GmbH with its simus classmate product family is one of the market leaders in the field of automatic classification of CAD models, data cleansing of mass data, searching and finding existing data and automatic calculation. The independent company offers experience from over 400 successful projects in the mechanical and plant engineering, automotive and electrical engineering sectors. The simus classmate product family integrates with leading 3D CAD and PLM solutions as well as ERP systems such as SAP.