Master data preparation for SAP systems

But without established standards, proven procedures and efficient tools, optimizing ERP master data quickly becomes a Sisyphean task.

Work.

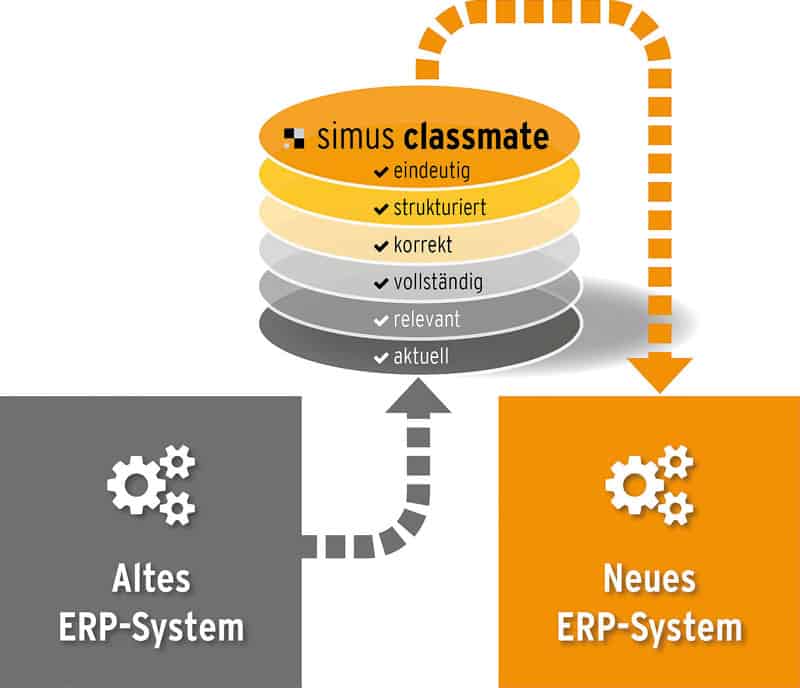

ERP systems house many thousands of master records that are subject to a cycle of creeping degradation due to mis-entry, inconsistent terminology, outdated data, different procedures, lack of conventions and responsibilities. A sustainable optimization project must therefore achieve two goals:

Master data quality must be redefined in a tour de force, the extensive data treasure must be updated, cleansed and raised to a new level.

Appropriate means and measures must be taken to prevent the possible erosion process of data quality from starting again. This is where Master Data Governance (MDG) comes into play.

Today's ERP systems, it should be noted right away, contain neither efficient on-board tools that support one-time master data optimization, nor routines or functions for ongoing quality assurance.

Efficient tools for master data preparation

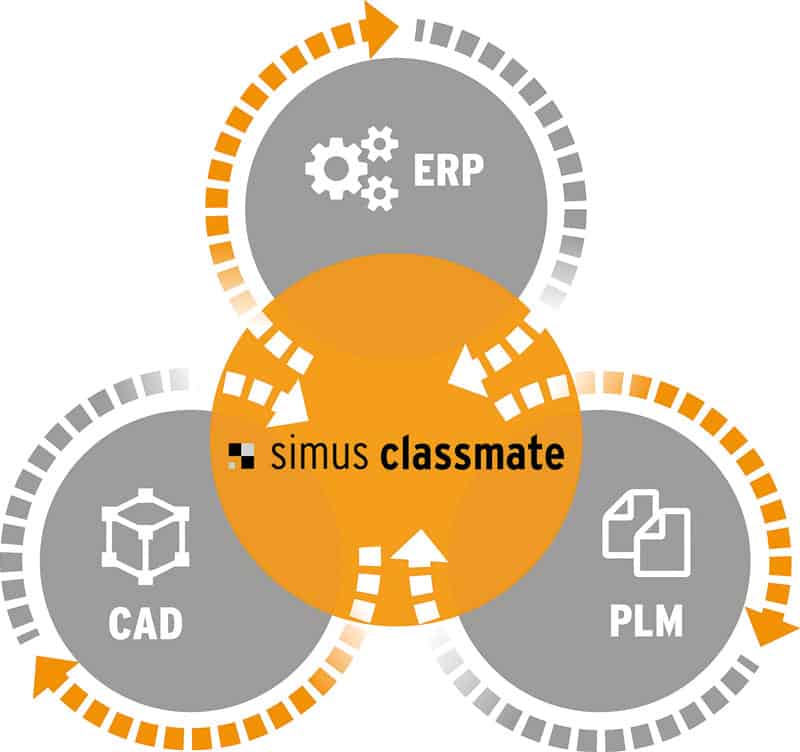

simus systems fills this gap with its patented software suite simus class-mate. The software modules classmate DATA and classmate CAD use predefined rules to analyze data sets of any size from relevant in-house sources such as databases, spreadsheets or CAD, ERP and PDM systems. Meanwhile, the software captures typical features that serve as the basis for a class definition. In the case of 3D CAD models, the classification is additionally based on geometry and meta data.

Know-how and Best Practices

In addition to the software, simus systems, as a service provider, brings a proven project methodology and standardized basic sets of rules to the collaboration. After all, the specialist for technical mass data has successfully completed more than 350 projects for around 220 customers in mechanical and plant engineering, the automotive industry and electrical engineering over the past 20 years. Detailed knowledge of the structure and functioning of SAP's ERP systems has led to the development of interfaces that ensure data exchange. This experience, the industry knowledge, the specially developed software and the professional project methodology improve the cooperation with the customers.

Image rights: simus systems GmbH.

Clear goals, accurate results

It begins with a preliminary project that creates clarity about the potentials and the internal and external efforts behind them. For this purpose, the customer provides the data volume to be processed and initially processes it as an example. Based on the results, the goals for the actual project are defined in workshops and discussions. They start with a functional reorganization of the master data and often include the classification of standard and purchased parts as well as the creation of additional, customer-specific functional classes that significantly increase the reuse rate of materials. Those who design their own products will need a geometric classification of the 3D-CAD-

Include models.

Change rules instead of editing data

At the start of the project, the relevant data is read out from the ERP systems concerned and processed in classmate DATA. According to initially neutral rules for preparation and optimization, the data is sorted, enriched and stored in a results database. The results can now be filtered and viewed with the classmate FINDER search engine to find any errors, duplicates or inaccuracies. The results are checked in workshops with the affected departments of the customer, which take place online or on site. However, the discrepancies and errors are not corrected via individual data records, but by changing the underlying formatting rules.

Thanks to the rule-based approach, the classification can be adapted to any use case. Data is automatically structured into the appropriate classes. Thus, even in the face of huge amounts of data, the desired results can be achieved within hours. Thanks to this methodology of existing best practices, up to 80 percent of the effort for data processing is saved, both on the part of the customer and the service provider. The data, including the new structure, is then transferred to the ERP system.

Sustainable assurance of data quality

In order to maintain the quality of the material master data once it has been achieved, the classmate FINDER already known from the project is used to implement a material master request process for new parts according to Master Data Governance. In this process, users submit a material request when they cannot find a desired part in the inventory. A master data center reviews the material requests. Automatic processes and email notifications are set up for this purpose. After a positive decision, the material is automatically created in ERP systems such as SAP via simus classmate.

Cross-company care process

The maintenance of material masters by several departments, from engineering to marketing, can also be automated with a customizable process. An authorization concept ensures security, intelligent presettings reduce the effort and prevent incorrect entries. The process can even span distributed locations and be adapted to different workflows, for example for different types of materials. Intelligent support for routine tasks accelerates throughput times, and the database remains up-to-date and of high quality.

Easy integration with SAP

Seamless integration with ERP systems from SAP has proven itself at many companies. They benefit from the high usability, flexibility and transparency of the processes set up without giving up the data sovereignty of the ERP system. For this purpose, all results of the simus software are written to a database, which is used for all functions. The results are then synchronized with the ERP system at adjustable intervals. In this way, workflows can be defined independently of SAP - but the results are available centrally for many applications such as Product Lifecycle Management or Engineering Control Center (ECTR).

About simus systems

simus systems GmbH, founded in 2002 and headquartered in Karlsruhe, is one of the market leaders in the field of automatic classification of CAD models, data cleansing of mass data, search and find of existing data and automatic calculation with its product family simus classmate.