APICON Data Master - a comprehensive tool for the data lifecycle in SAP

Data Lifecycle in SAP

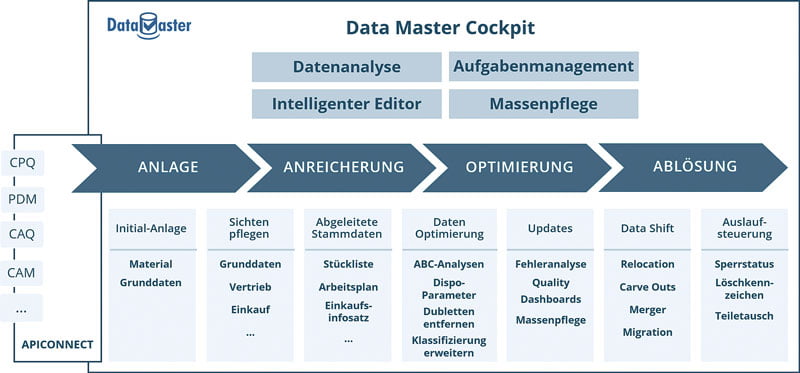

The lifecycle of master data is therefore becoming shorter and shorter. Master data tools that offer additional smart functions for the entire lifecycle provide a remedy. APICON Data Master is a fully integrated add-on in SAP ERP that not only automates the creation and modification of SAP material, but also conveniently processes derived master data such as purchasing info records, bills of materials or routings. How do companies that use APICON Data Master overcome their challenges in the data lifecycle?

Data Lifecycle in Practice

The life cycle of an article often starts in a CAD or PDM system. With the APICONNECT interface, the APICON Data Master saves tedious typing and avoids transfer errors, as data can be easily imported from the previous system. The responsible employees receive a task in their worklist, which leads directly to further maintenance and initial creation of the material master. Where possible, no-code rules automatically determine field values.

Everyone should know when they have to complete which data maintenance tasks. This is provided by task management in Data Master, an uncomplicated and flexible workflow solution. Standard workflows are often too rigid and cause problems when deviations occur. Data Master tasks, on the other hand, can be flexibly adapted in the event of disruptions. The master data manager keeps track of the processing progress of master data maintenance at all times. This is an important advantage, because after the initial creation, further views are added by the specialist departments such as sales, purchasing or work preparation. This works via a traffic light system and dashboards with diagrams.

For Amphenol-Tuchel, leading manufacturer of electrical connectors, the processes for creating new materials were crucial. The parallel processing of tasks in the APICON Data Master task management significantly accelerates the entire process. The departments can process their worklists individually, yet the entire process is controlled by the system.

More benefits through maintenance of the derived master data

Bills of material, purchasing info records and routings belong to the derived master data on which changes in the material master have a direct effect. With APICON Data Master, intelligent editors with rules or mass changes reduce the maintenance effort here as well.

Again the example of Amphenol-Tuchel: in addition to the SAP material master, classification, bills of materials, purchasing info records and other derived data can be created quickly and efficiently in the process chain. In some cases, a single mouse click is sufficient, as assignment rules automatically determine field values with optimal data quality.

Over time, data ages, so it requires maintenance. Data analysis in the Data Master provides individual data quality dashboards without programming. This is also the case at APICON customer Schaeffler: In 75 plants worldwide, Industrial Engineering (IE) is one of the most complex areas within Schaeffler. The area of responsibility includes bills of materials, routings, work centers and manufacturing versions. Schaeffler currently has about 400,000 routings and BOMs and more than 2.5 million internal processing steps. On a regular basis, the Data Master performs more than 20 quality checks across all IE master data objects and provides dashboards with detailed error logs. As a perfect complement, task management allows the person responsible for each plant/segment and IE object to be addressed to perform data cleansing using mass maintenance in Data Master.

Data tuning for dispo parameters, duplicates or classification

Further optimization functions are ABC analyses or the updating of MRP parameters. If you want to get an overview of stocks, sales documents or material documents, the data analysis with so-called strip charts helps. For example, these graphically display all materials grouped by plant, storage location and material type. Clicking on a segment, for example material masters in plant 1000, immediately adjusts the selection and shows only storage locations and material types for this plant. The visualization across several analysis levels gives the planner an excellent overview.

Duplicates are a serious source of errors in master data. When creating new business partners, it is at least possible to check for address fields in the SAP standard. The situation is different when material masters or parts lists have to be checked for duplicates and cleaned up. In APICON Data Master, employees from the specialist departments can parameterize and also carry out checks for any data objects and fields. The real challenge is to eliminate the detected duplicates. Once the golden record has been defined, statuses can be implemented and, if necessary, repostings can be made.

In the case of the material master, but also for other data, additional information is stored in a structured manner in characteristics via classification. In the course of the life cycle of master data, these characteristics must also be adapted. If the data type has to be changed, one fails if characteristics already carry valuations. APICON Data Master offers a solution here as well: Via mass maintenance, the characteristic values are temporarily refilled in order to then carry out the changes.

Efficient updates and migrations via mass maintenance

In these updates, the data analysis and mass change functions in the Data Master support the master data manager. Other scenarios include migrations, mergers or carve-outs of data from different SAP systems. These are then projects and not daily business. APICON Data Master is a comprehensive tool for efficient data optimization throughout the entire data lifecycle in SAP. The modular architecture of the Data Master ensures custom-fit, lean and extensible solutions for master data management in SAP.