Intelligent production planning in SAP system landscapes

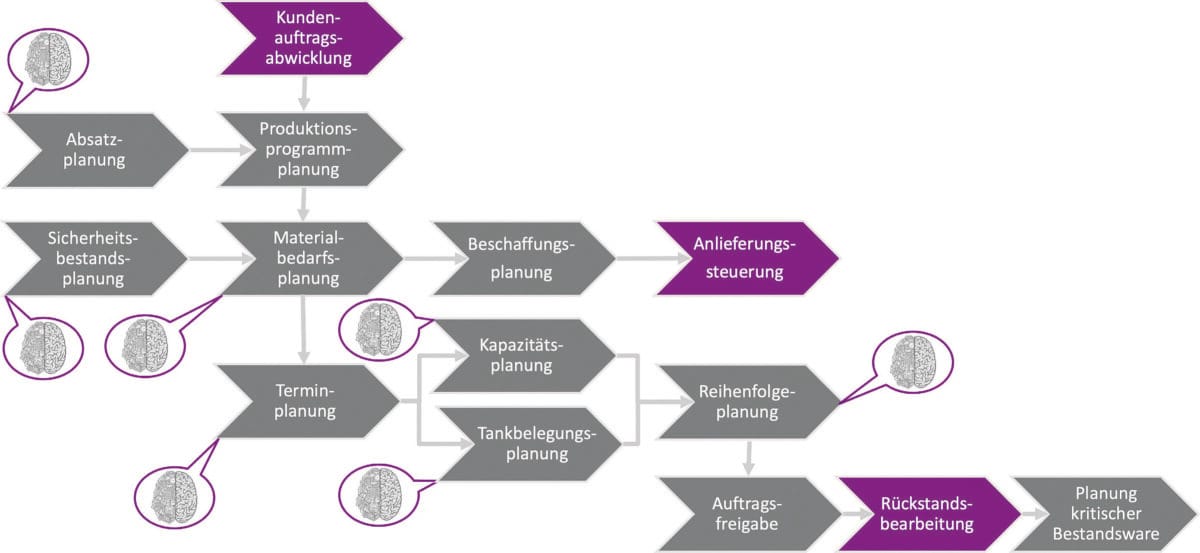

Cimt AIPlanner was specially developed for production companies in the food, mechanical engineering, retail and consumer goods industries and is used precisely where traditional systems reach their limits. The software supports all core planning tasks: from sales and safety stock planning, material and procurement planning to scheduling, capacity and tank allocation planning, sequence planning and the management of MHD-critical stocks. The aim is to use artificial intelligence to transform complex data volumes into reliable and flexibly adaptable plans - directly in the SAP or Microsoft Navision landscape.

APO alternative: More flexible than IBP

AIPlanner is an AI-based alternative to SAP SCM APO, whose standard maintenance expires at the end of 2027. Unlike the successor system SAP IBP, AIPlanner can be operated both in the cloud and on-premises. This gives companies complete freedom of choice and allows them to continue using their existing IT landscape optimally.

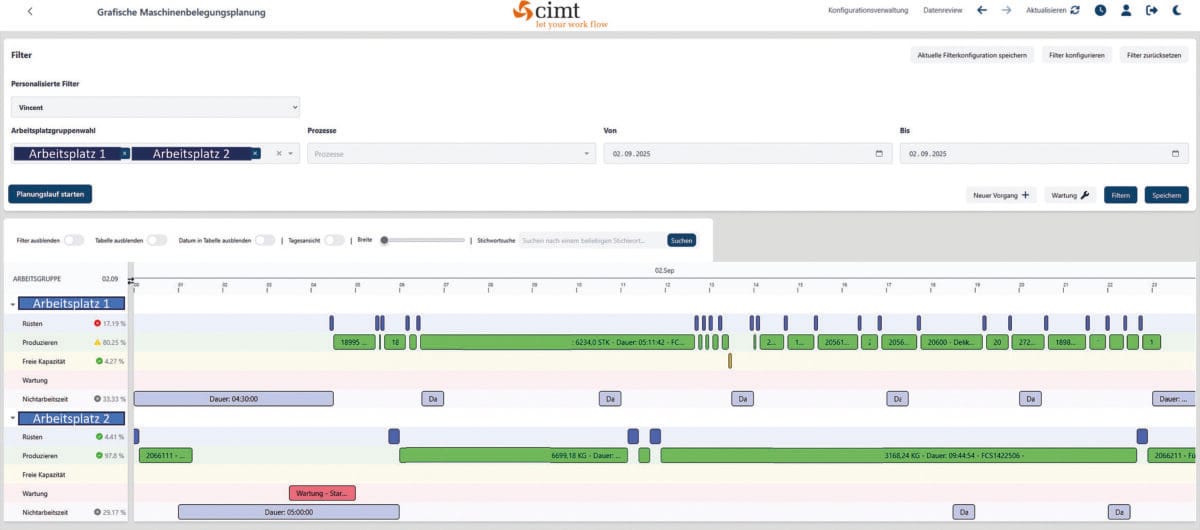

Cimt-AIPlanner app: graphical machine allocation planning.

One decisive advantage is the deep integration into S/4 Hana and Microsoft Navision. This allows planning processes to be mapped without media disruptions. The embedding of state-of-the-art machine learning algorithms is particularly innovative: Reinforcement learning continuously improves complex decisions in sequence and capacity planning. Through simulations and feedback, the system learns which strategies ensure adherence to deadlines, shorten set-up times and optimize capacity utilization - much more efficiently than traditional optimization methods.

Transformer networks set new standards in sales forecasting. They process extensive influencing factors such as sales promotions, prices, public holidays, seasonal factors, cannibalization effects, weather or competitor activities and therefore deliver significantly more precise forecasts. The higher forecasting quality - especially for short-term orders - directly improves inventory and production decisions. A key benefit of AIPlanner is the increase in forecasting quality. Order fluctuations are better anticipated and requirements are planned more reliably. This reduces ad hoc procurements, lowers uncertainties and allows the reduction of excessive safety stocks - with positive effects on capital commitment and storage costs.

Better planning is reflected in higher delivery capability and an increased service level. Customer orders can be fulfilled more reliably and on time. At the same time, AIPlanner ensures more even capacity utilization and more efficient workforce planning: overtime and idle time are reduced, while employees can be deployed more predictably. In the food and consumer goods industry in particular, AIPlanner avoids overproduction by systematically taking into account best-before dates and remaining shelf life. This significantly reduces the rate of written-off products - a contribution to cost reduction and sustainability.

Dynamic rescheduling in minutes

The AIPlanner shows its strength above all in its speed: new customer orders or machine breakdowns do not lead to planning chaos - the system recalculates the entire planning within minutes. Companies therefore remain flexible and able to act at all times.

Planning processes with AI in Cimt AIPlanner.

Apps and visualizations

The AIPlanner provides up-to-date planning data in web-based apps. In sales planning, tabular and graphical forecasts can be created in both monetary and quantitative form, with aggregation possible down to product group or customer level. Daily planning covers material requirements in the short-term horizon as well as rough planning over longer periods and offers a transparent visualization of multi-level order networks.

A graphical machine assignment enables the visual display of set-up and production processes, maintenance, shifts or breaks, whereby manual rescheduling is also possible.

In addition, the tabular machine allocation provides a chronological overview of the processes with an integrated release function. For critical stock items, stocks with an imminent expiry date are displayed. In master data maintenance and validation, the system automatically detects inconsistent or missing master data. Finally, tank allocation planning provides support by visualizing fill levels and tank contents over time.

The underlying AI server continuously optimizes key performance indicators such as forecast quality, ranges, adherence to delivery dates, set-up times and capacity utilization. Competing targets are weighted in a target function and balanced to achieve an optimum overall result.

The calculation is based on current transaction data (sales plans, sales orders, stocks, tank levels, production orders, dependent requirements, purchase requisitions, orders, capacity and personnel requirements) and consistent master data (material masters, work centers, production versions, work plans, parts lists, shift models, technical setup sequences, customer and supplier masters).

Efficient, resilient and sustainable

The effects are measurable: AIPlanner boosts efficiency, increases resilience to market and supply chain disruptions and reduces the environmental footprint through more precise inventory management. Production planning is thus evolving from a reactive to a proactive and increasingly autonomous process.

The AIPlanner was originally developed by CompanyMind. In August 2025, Cimt ai solutions ag acquired CompanyMind, thereby laying the foundation for sustainable further development.

By combining the SAP expertise of the Cimt Group with the AI know-how from AIPlanner development, the solution is being continuously expanded both technologically and strategically. Companies thus benefit from an innovative product supported by a strong organization in the background.