Industrial Digitalization

It starts with return on investment, continues with security and resilience, and extends to digital twin. Only holistic approaches guarantee sustainable value creation.

Orbis is realigning itself strategically and organizationally, combining its expertise in (intra)logistics and production in the newly created Manufacturing and Logistics division. The Logistics and Manufacturing divisions are beneficiaries of the digital transformation that Orbis is taking into account in its future organization. "We will of course continue to serve our customers as we do today, but we are also building a new pillar that will expand the business unit and complement the existing areas of expertise," says Pascal Kiefer, Head of the SAP Manufacturing Business Center at Orbis, defining the new challenges.

The project to digitize manufacturing processes is about 40 years old and began with CIM, Computer Integrated Manufacturing. Shouldn't we be coming to the end of this development soon? At the beginning of the E3 interview, Pascal Kiefer explains: "The digitization and automation of manufacturing processes actually started about 40 years ago with the concept of Computer Integrated Manufacturing, CIM. But that was just the beginning of a continuous evolution. It's important to understand that technology and the needs of the manufacturing industry are constantly changing over time, so there is no real end to this evolution.

There are several reasons why the evolution of digital manufacturing and automation continues: Technology is constantly evolving, providing new ways to optimize manufacturing processes. This includes advances in artificial intelligence, robotics, the Internet of Things (IoT), and data analytics. To remain competitive, manufacturing companies must be able to produce more efficiently and with greater agility. Digitalization helps reduce costs, improve quality, and bring products to market faster. The manufacturing industry is under increasing pressure to become more sustainable and use resources more efficiently. Digitalization can help reduce energy consumption and waste. Customers increasingly expect customized products in less time. Digital technologies make it possible to meet these demands.

"Overall, there are many reasons why the evolution of digital manufacturing and automation is continuing," adds Frank Wilhelm, Head of Business Center SAP Manufacturing at Orbis. "It is a continuous process that adapts to changing needs and opportunities. There is no clear end to this evolution, but it will continue to evolve to meet the needs of the manufacturing industry.

Digital decade

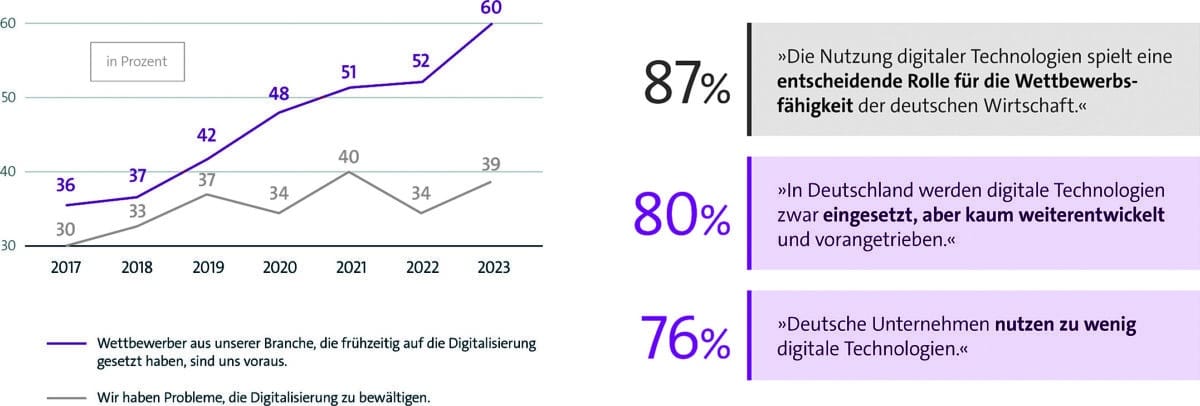

Many companies are increasingly concerned about losing ground to competitors. A clear majority of companies see competitors ahead of them because they focused on digitalization early on. This is an all-time high. Two-thirds (64 percent) currently see their own company as a digital straggler, while one-third (35 percent) see themselves as a pioneer. These are the results of a representative survey of 602 companies in Germany with 20 or more employees commissioned by the digital association Bitkom. 87 percent are convinced that the use of digital technologies plays a decisive role in the competitiveness of the German economy. "Companies have recognized the importance of digitalization for their own future. However, they do not seem to know how to approach digitalization. For each individual company, as well as for the German economy as a whole, the motto must be: make the 2020s the digital decade!" demanded the new Bitkom President Ralf Wintergerst when presenting the study. "Germany used to be the land of poets and thinkers. In the future, Germany must be the country of poets, thinkers and digitizers.

In general, Pascal Kiefer believes that Industry 4.0 and IoT have revolutionized the manufacturing landscape by modernizing traditional production methods and helping companies become more agile, efficient and competitive. "They have paved the way for smart manufacturing, where data and technology go hand in hand to create value," Frank Wilhelm agrees with his colleagues. Industry 4.0 integrates machines, plants and processes in a networked environment. By connecting these systems, data can be collected, transmitted and analyzed in real time. "This enables better monitoring and control of production, resulting in higher efficiency, lower error rates and reduced downtime," Frank Wilhelm continues. IoT-enabled devices continuously collect data from the production floor. This data is analyzed to gain insight into the performance and condition of machines. This enables predictive maintenance, where problems are detected before they lead to failures, thus reducing maintenance costs.

Networked, flexible and real-time

"Networking machines enables flexible production, where machines and processes can be adapted to new product requirements," says Pascal Kiefer, who has worked on other successful Orbis customer projects. This allows new products to be brought to market quickly and customized products to be mass-produced.

"By collecting and analyzing data in real time, quality problems can be detected and corrected at an early stage," explains Frank Wilhelm. "This leads to higher product quality and reduces the amount of waste.

But what are the success criteria for digitizing a manufacturing industry? In business management, in the organization of processes, or in technologies such as SAP APO or IBP (Integrated Business Planning)? "The successful digitalization of a manufacturing industry requires a comprehensive approach that combines technological innovation, organizational adjustments, and a clear strategic focus," says Frank Wilhelm, head of the SAP Manufacturing Business Center at Orbis: "A clear digitalization strategy with specific goals is crucial. Companies need to know what they want to achieve—be it increased efficiency, improved quality, cost reduction, or other goals.

Pascal Kiefer points towards a comprehensive data strategy during the E3 conversation: "A sound data strategy is essential. Companies need to decide what data to collect, how to collect it, how to store it, how to analyze it, and how to protect it. German companies believe that business success is increasingly based on data. Seven percent of respondents say that their business depends exclusively or very much on data-driven business models. Twice as many, 14 percent, expect this to be the case in two years. This means that one in seven German companies would base their core business on data. At the same time, German companies see a great need to catch up in the development of data-driven business models. Only one in a hundred German companies sees itself as a pioneer in the data economy. In their own opinion, 19 percent have missed the boat. These are the findings of a representative survey of 604 companies from all sectors of the economy commissioned by the digital industry association Bitkom.

"Data and its responsible use are becoming increasingly important in the global economy. This ranges from the analysis of mobility data in the transportation sector, predictive maintenance in industrial companies and smart farming in agriculture to the demand-oriented control of energy storage systems for a sustainable power supply," said Bitkom CEO Bernhard Rohleder. "As a resource-poor nation, we cannot afford to lock data away in silos and not forgo its use. By taking a consistent step towards the data economy, Germany can become more competitive, reduce the risk of crises, conserve resources and improve the quality of life at the same time."

The right choice and integration of technologies such as IoT, AI, cloud computing and data analytics are important. In the E3 interview, Pascal Kiefer adds that employees must be prepared and trained for the changes. An effective change management program helps to reduce resistance and promote acceptance of new technologies. Digitization requires collaboration between different departments, including production, IT, engineering, and business development. An interdisciplinary team can develop the best possible solutions.

IT and IoT platforms

An IT platform mindset is taking hold in many application areas, but are there platforms for industrial production? "Yes, there are IoT platforms for industrial production that aim to improve efficiency, connectivity and controllability in the industry," explains Frank Wilhelm. "They provide a central infrastructure on which various IoT devices and sensors can collect, transmit and analyze data. Examples of IoT platforms are Microsoft Azure IoT and AWS IoT."

Germany was the land of poets and thinkers. In the future, we must be the land of poets, thinkers and digitizers.

Ralf Wintergerst,

President,

Bitkom

Two terms are shaping the technological evolution of industrial manufacturing: Interoperability and Composable ERP. Put simply, in terms of the IoT, every thing must be able to communicate with every other thing, and users must be allowed to freely and independently compose and orchestrate their IT tools. "In order for a company to successfully network all relevant process participants, e.g. production plants, logistics systems, platform services, etc., the smooth and largely automated transfer of information is essential. The key word here is interoperability. Interoperability is the ability of devices or services to communicate with each other independently, without being dependent on another actor," says Pascal Kiefer. With Distributed Shopfloor Processing (DSP), Orbis has developed a solution whose central function is process modeling and seamless communication between a wide variety of systems and partners. Communication between devices and services is independent of any actor or system. "This allows the independence of specialized systems to be maintained so that their potential can be fully exploited in the overall process—keyword best-of-breed," emphasizes Pascal Kiefer.

Digital Twin

Because of this complexity, many Industry 4.0 companies rely on a digital image of their production, supply chain and related logistics processes—a digital twin. Combined with the right tools, it also enables automated preventative and corrective actions to respond flexibly to the complex demands of ever-changing manufacturing processes. Digital twins are establishing themselves as a planning tool in industrial production, and Frank Wilhelm explains their function in detail: "A digital twin is a virtual model or digital representation of a physical object, process or system. This virtual model is continuously updated with real-time data from the physical world to create an accurate representation of the real object or process. Digital twins are used in a variety of fields, including industrial manufacturing and the Internet of Things.

Digitized companies are leading the race. To what extent do the following statements on digitization apply to your company? n=602, percentages for "Fully agree" or "Somewhat agree", source: Bitkom 2023.

Pascal Kiefer notes that by continuously collecting data from the physical counterpart, the digital twin can be used to analyze trends that help optimize processes. By creating a digital twin, companies can model and optimize the energy consumption of plants and processes. In addition to manufacturing, logistics, and supply chain management have been much discussed in recent years. What are the current challenges in SCM? "A company's supply chain has a major impact on the entire organization," says Frank Wilhelm. "Today, it is no longer enough to make it cost-conscious and efficient. Customers expect maximum transparency, short production and delivery times, and low costs. To meet these demands, companies must link all processes and manage them holistically. "The goal is to create a transparent network across the entire value chain, plan internal processes, and oversee them efficiently," adds his colleague Pascal Kiefer.

Risk Resistant SCM

To avoid supply chain disruptions and make it risk resilient, it is essential to connect the supply chain to the rest of the enterprise and its data. Resilient supply chains are the foundation for meeting any challenge with strength. Today, the cloud plays an important role in resilient supply chains. From the core with RISE with SAP, to planning with SAP IBP (Integrated Business Planning as the cloud successor to on-premises APO) and solutions for logistics with SAP EWM, TM, Yard Logistics and the SAP Business Network for Logistics, to production with SAP Digital Manufacturing and service with SAP Field Service Management. Orbis is a competent partner for SAP's solutions in the context of the digital supply chain. "We complement this portfolio with our own integrated solutions," emphasizes Pascal Kiefer. Our own solutions such as MES, DSP (Distributed Shopfloor Processing) and a wide range of intralogistics add-ons complete the Orbis portfolio.

Agility with SAP BTP

The SAP Business Technology Platform (BTP) enables the seamless integration of SAP applications with other applications and systems, both inside and outside the company. "This facilitates the exchange of information and the automation of business processes," says Frank Wilhelm of Orbis' successful projects. BTP enables companies to extend their existing SAP applications through individual extensions and customizations. This promotes agility and flexibility in adapting software to specific business needs. "SAP BTP provides developers with a variety of tools and frameworks for creating and integrating applications. These include low-code and no-code development tools that accelerate application development," says Pascal Kiefer, explaining the many benefits of BTP. "The platform offers advanced data management and analysis capabilities. Organizations can efficiently analyze large amounts of data and gain valuable insights.

As a resource-poor nation, we cannot afford to lock data away in silos and forgo its use.

Bernd Rohleder,

Chief Executive Officer,

Bitkom

Manufacturing and SCM

"The future of manufacturing, logistics, and supply chain management brings a variety of challenges, some of which are already apparent, while others may evolve over time," concludes Pascal Kiefer. "The ongoing digitalization and integration of technologies such as IoT, AI, and big data analytics will fundamentally change manufacturing and logistics. Adapting and ensuring data security are key challenges."

Bitkom, the digital industry association, knows that some companies are trying to set the course for digitalization. For example, only eleven percent of companies still have no digital strategy at all. "Many companies introduce a partial strategy for digitalization, but stop there, so there is no overall digital strategy positioning. It would make sense to have a digital vision and an overall strategy," says Bitkom President Ralf Wintergerst.

Other parameters of industrial digitalization are the demands for sustainability in production and logistics. This includes not only the reduction of emissions, but also the efficient use of resources and the minimization of waste. And fluctuations in global trade policy and trade conflicts can have a significant impact on supply chains. Companies must be flexible to adapt to changing market conditions.

End-to-end processes

"As an innovative consulting company, Orbis has been a reliable partner for its customers for years—especially in the inevitable advance of digitalization, especially in logistics and production. We approach our customers with the following vision," explains Frank Wilhelm: "Design and implementation of adaptive end-to-end processes on the shop floor level in distributed systems, decentralization, under integration of people, information and things.

Close cooperation and collaboration with scientific institutes means that the latest scientific findings can be incorporated both into the ongoing training of Orbis employees and into continuous product development. "This enables us to offer our customers continuous innovation across the entire service portfolio," says Pascal Kiefer. "We believe that in the future we will have to focus more and more on interoperable processes, where platforms will play a decisive role. The digitization of business processes will no longer be limited to the SAP universe. Thanks to our strong partnerships with SAP and Microsoft, as well as the Orbis products available on the market, we believe we are well positioned with our entire portfolio."

"Companies that integrate these advances into their business models and processes will be better positioned to remain competitive and meet the changing demands of their markets," concludes Frank Wilhelm, and Bitkom President Ralf Wintergerst says: "I would like to see more German speed not only in the digitization of administrations, but also in the digitization of companies.