SCM Optimization on S/4 and Hana for the Midmarket

Does a brownfield approach succeed or is the far more elaborate greenfield approach more sensible or perhaps even essential? How much (work) time and costs will be incurred by the changeover? All of these questions often cause deep worry lines, especially for medium-sized companies.

GIB, SAP partner and software developer for SCM optimization, is starting precisely there with the new suite and promises SMEs a valid solution with additional benefits in the changeover to S/4.

S/4 and Hana are undoubtedly the future and drivers of digitization, but also an upcoming tour de force for all those companies that have SAP in use.

GIB has developed a solution to make the benefits of the enormous potential of Hana technology available, especially for medium-sized businesses: The new GIB suite "SCX - Supply Chain Excellence" uses the digital core of S/4 and the high-performance Hana technology for a holistic view of the digital supply chain.

This new end-to-end solution is the result of expertise developed over 25 years of close collaboration with customers, among others.

"What do those who are involved in the supply chain process on a daily basis need? Where is there a need for optimization, where can the SAP standard be usefully supplemented?

We have experienced this first-hand from our customers and have thus already been able to deliver exactly the supplements to the SAP standard that are needed. The sum of these experiences has now led to the development of GIB-SCX: a suite for excellent supply chain processes on S/4 Hana".

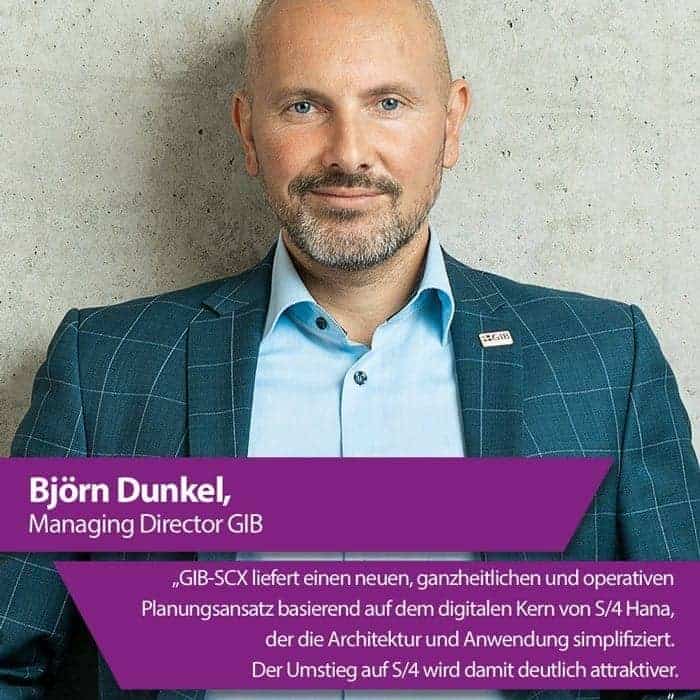

explains Björn Dunkel, Managing Director GIB.

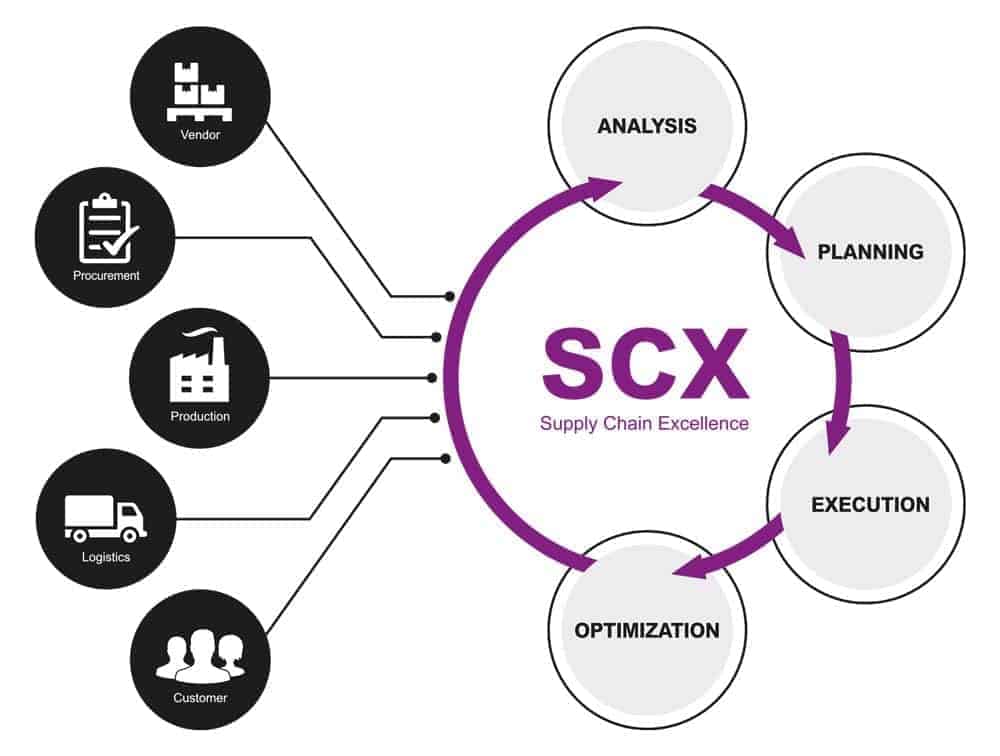

Analysis, planning, execution, optimization

The advantages lie above all in the holistic and process-based view of the supply chain. Instead of the silo thinking that has been common up to now, the focus opens up to the entire supply chain and focuses on consistency.

"We are moving away from modular design and now offer a much more organic solution for the entire supply chain processes with the GIB-SCX"

so dark.

The aim is to eliminate "island optimization" in individual areas, which has no interconnection with the preceding or subsequent processes and thus often fizzles out.

In this way, a holistic optimization can succeed, which also achieves the greatest economic success. This is because adjustments, for example in sales planning, do not remain within this one area, but also have an impact on inventory planning, production planning and order processing.

The core of the GIB-SCX is the control loop, which consists of the process steps analysis, planning, execution and optimization and ensures continuous improvement.

Starting with an analysis of the current status and the actual processes, strategic and operational action planning for optimization is carried out, always on the basis of current data and key figures thanks to the powerful Hana technology. A meaningful simulation is followed by operational implementation and comprehensive control.

The focus is on performance, usability and the use of state-of-the-art system-immanent intelligence. Specific key figures and systematic evaluations make successes and potentials visible.

Optimization takes place in the course of this continuous improvement process. The success is reflected in a significant reduction in costs, an increase in delivery readiness, greater transparency and the acceleration of processes.

With the new suite, the software manufacturer continues to primarily address medium-sized businesses. This is because SCX also uses the enormous performance of Hana technology for new features that turn the switch from a mere necessity into an economically worthwhile investment.

"Supply chain optimization is essential for the economic success of a company, but at the same time it represents an enormously large block of tasks that is often very difficult for medium-sized companies to manage. GIB-SCX breaks up this block and simplifies the process".

Dunkel continues.

Barometer for supply chain optimization

A central component of this process is the GIB-SCX-Indicator, a barometer for the current maturity level of the supply chain. At the push of a button, a single indicator reflects whether there is a need for action.

Faulty planning, such as too little demand in the system or planning against infinite capacity, lowers the value of the indicator. A corresponding scale value signals the urgency of the need for action.

The entry into further key figures, which the indicator forms on the basis of the company-specific data in the SAP system, shows at which point in the process chain there is potential for optimization.

The software enables further detailed analyses, provides recommendations for action and offers control options so that the optimization measures can be implemented directly in the S and OP process.

The information gained from this can be further processed in a meaningful way by simulating production planning. Here, the planner has the possibility to transfer all available variables, for example order situation, forecast as well as machine capacities and material stocks, into a production plan.

By changing individual variables, the planner can determine how this production plan can be optimized. This simulation option significantly improves the planning result and prevents bottlenecks from being detected only during the production phase.

Production is thus carried out with foresight, which has a positive effect on material availability, inventory and setup times and brings lasting effects on costs, delivery reliability and capital commitment.

In addition, SCX also provides clear indications of the need for optimization in the process itself. Often, the impact of changes in the supply chain process only becomes apparent after several months.

It is a less effective trial-and-error process if it is not known in advance whether the process adjustment will have a positive or negative impact.

In the analysis and optimization process, SCX clearly shows which adjusting screws can be turned and to what extent, and opens up meaningful room for maneuver for the supply chain manager, within which he can move with maximum security and, as a rule, great positive effects.

Horizontal and vertical supply chain with S/4

S/4 Hana opens up a new world of possibilities for GIB. A world that the majority of customers do not yet dare to enter.

"One thing is clear: we have a large customer base that relies on our software solutions every day and that we also want to support in the best possible way in the process of switching to S/4.

That is why we have put a lot of programming effort into ensuring that the proven functionalities of the GIB Suite can also be run with high performance in the S/4 Hana environment. Our customers can thus implement the GIB Suite according to the brownfield approach without any effort".

Björn Dunkel explains GIB's hybrid approach to migration from R/3 to S/4.

"Our proven GIB suite is almost programmed out in R/3 - here we have exhausted as far as possible all possibilities to offer an optimal complement to the SAP standard. S/4 offers us new ground for innovations, which we would like to offer within the framework of GIB-SCX".

Dunkel explains.

"So if you're ready to take a greenfield approach and completely rethink your supply chain processes, you'll get an absolutely forward-looking software solution in GIB-SCX with plenty of scope for further innovative functions that will once again significantly optimize your day-to-day work."

GIB already has some of these in its quiver, such as the KPI Tower for a clear presentation and tracking of important key figures (Key Performance Indicators) and a WCM tool that enables holistic entrepreneurial optimization according to the World Class Manufacturing principle.

These new functionalities are inconceivable without S/4 Hana, as the old R/3 basis does not offer the required performance for this. A switch to S/4 will therefore be more than just a necessary step for GIB customers.

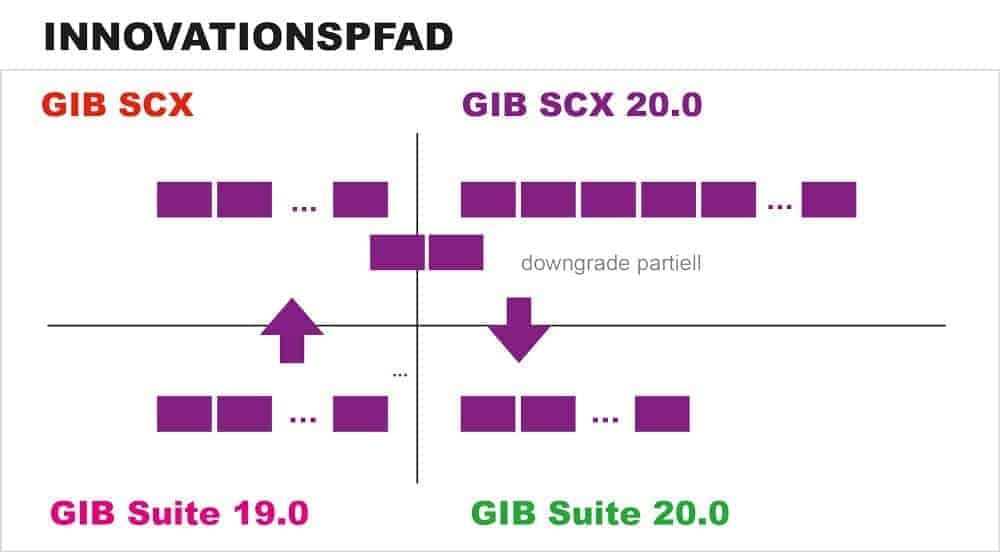

"Our strategy is clearly focused on S/4. From 2020, we will develop exclusively in this new world. What can be translated into the old R/3 world in a meaningful way, we will of course downgrade for our customers who have not yet dared to make the switch.

But the emphasis here is clearly on 'useful' - we will take a close look at which functionalities come into question in each individual case."

The future therefore clearly lies in the new GIB-SCX suite, which in addition to horizontal networking also offers potential for vertical value creation.

In cooperation with the parent company ifm, a globally active and leading manufacturer of sensor technology, GIB has succeeded in developing a unique link between the worlds that is perfectly integrated in the SAP system.

With the GIB solution "Shopfloor Integration - SFI", which connects sensor data with the ERP system. For Björn Dunkel, clearly an important branch of the future:

"In the future, the connection of the vertical and horizontal levels will certainly be a key USP of GIB-SCX. We are working on this at full speed."