Revolutionary planning concept gets a grip on variability within the supply chain

Tomorrow's intelligent enterprises - known by the buzzword "Intelligent Enterprise" - use data effectively to automate processes. Take DDMRP, Demand-Driven Material Requirements Planning, for example: DDMRP uses actual customer orders in combination with strategic decoupling points and inventory, time and capacity buffers to propagate the demand signal through the supply chain. As a result, the planning concept reduces variability and the "bullwhip effect" within the supply chain, which can lead to a reduction in inventory while increasing the level of service to the customer.

As part of a strategic development partnership, SAP and Camelot ITLab are developing the new SAP Integrated Business Planning for Demand-Driven Replenishment module, which is part of the SAP IBP standard and covers all functionalities of DDMRP.

DDMRP uses many granular, real-time indicators to determine demand

The requirement to meet the "demand" of end customers has always been inherent in the basic idea of supply chain management. Traditional supply chain planning approaches use forecasts of future customer demand to define what should be purchased, produced and transported, when and how.

However, since the introduction of these MRP systems in the 1950s, the planning environment has changed significantly. Logistics networks have become more complex, product portfolios are growing, product life cycles are becoming shorter and shorter, and customers' requirements regarding delivery times are increasing. This increasingly leads to uncertainties in the supply chain. Volatility is growing.

It is hardly possible to make accurate demand forecasts anymore. Demand forecasts in an agile business environment sometimes deviate by up to 50 percent from actual demand. As a result, the wrong quantities are procured, manufactured or delivered to the wrong places. The quality of service to the customer declines.

DDMRP enables companies to get a grip on this challenge - in particular the variability in the supply chain. The planning concept represents a disruptive approach, as companies need to radically redefine their planning processes in order to be more agile in the marketplace while operating more efficiently.

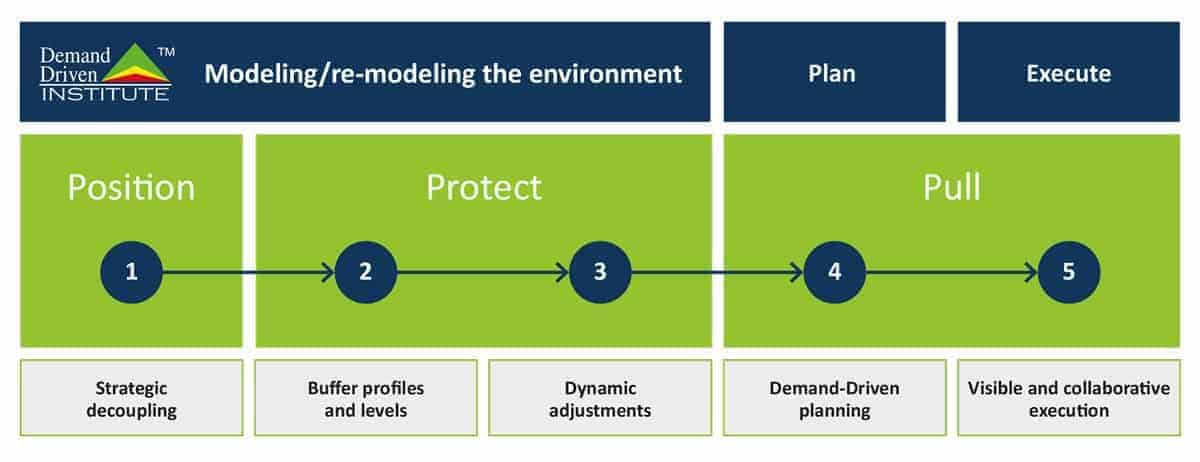

The DDMRP Concept: Five Steps to Actual Needs Assessment

Demand-driven material requirements planning is divided into five steps. These are run through cyclically, for example once a day. They include the positioning of decoupling points ("Position"), the definition of stock limits ("Protect") and the concrete planning and its execution ("Pull").

Step one (Strategic Decoupling) defines at which levels material inventories are stored. These decoupling points are defined along the entire supply chain. With their help, optimal inventory buffers can be positioned. The buffers act as "shock absorbers" that cushion fluctuations at each distribution and manufacturing stage.

In steps two and three, the planners design the inventory buffers optimally and adjust them dynamically. To this end, in the second step (Buffer Profiles and Levels), upper stock limits are first defined at the decoupling points and the buffers are thus suitably dimensioned. In the third step (Dynamic Adjustments), planners make adjustments to the previously calculated buffer sizes. This allows short-term adjustments of the input parameters or even the consideration of the planners' experience.

In step four (Demand-Driven Planning), purchase orders are then generated at the individual storage points by evaluating actual inventory levels, outstanding stock receipts and future demand within the framework of the "Netflow Equation".

Finally, in step five (Visible and Collaborative Execution), planners receive execution support through alerts: for example, for parameterization and projected inventory history.

More efficiency, lower inventories and a higher quality of service

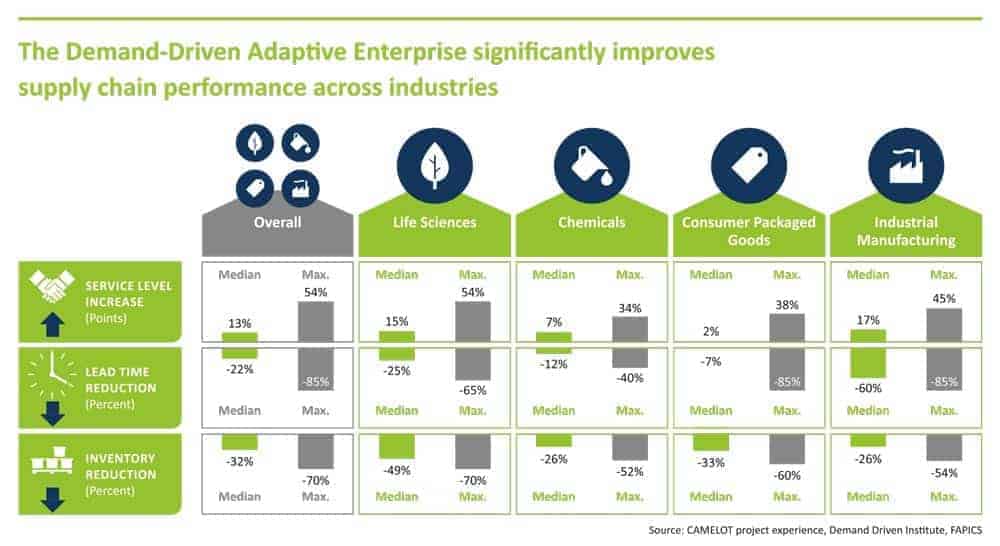

Many global companies in different industries use the "Demand-Driven" concept very successfully. They significantly reduce their variability and stabilize the flow of materials in their supply chain. The agility of the supply chain in these companies increases by up to 85 percent due to shorter lead times. In addition, inventories can be reduced by up to 70 percent and costs by up to 20 percent - with a simultaneous increase in service quality to customers.

SAP and Camelot ITLab integrate DDMRP into SAP IBP

Support of the individual steps by IT systems is the prerequisite for a successful implementation of DDMRP. SAP and Camelot ITLab have now integrated the DDMRP concept into the SAP standard Integrated Business Planning (SAP IBP). The solution supports all five steps described and enables companies to take a modern, customer demand-driven approach to planning their supply chains. The module has been available to SAP customers since May 2019 under the name "SAP Integrated Business Planning for Demand-Driven Replenishment".

SAP and Camelot ITLab have been working together in partnership for several years. Camelot ITLab brings its extensive knowledge as the largest global partner of the Demand Driven Institute (DDI) to this development partnership and will also act as an implementation partner for this new, joint solution. With this cooperation project, Camelot ITLab consolidates its position as a strategic partner for the joint development of functions for DDMRP within SAP IBP.

Camelot ITLab shows DDMRP module for SAP IBP at the DSAG annual congress

At this year's DSAG Annual Congress, Camelot ITLab will show which efficiency gains can be achieved with the new DDMRP module for SAP IBP. In addition, Camelot's experts will illustrate how supply chain planning and implementation are linked and how SAP solutions support here.

Other topics at the Camelot booth: data analysis with SAP tools, business and IT strategies for CRM and ERP users, Industrial IoT using acquired data in SAP S/4HANA, and blockchain scenarios from SAP practice.