MDM before ERP migration

Refrigeration system manufacturer Hauser operates several production plants in Austria and the Czech Republic, distribution centers in Europe and a site in Australia. Business is conducted using an ERP system whose maintenance has been discontinued. From 2025, the company plans to work with S/4 Hana from SAP worldwide. Since this decision was made in 2021, preparations for the migration have been progressing everywhere and financial accounting has already been converted.

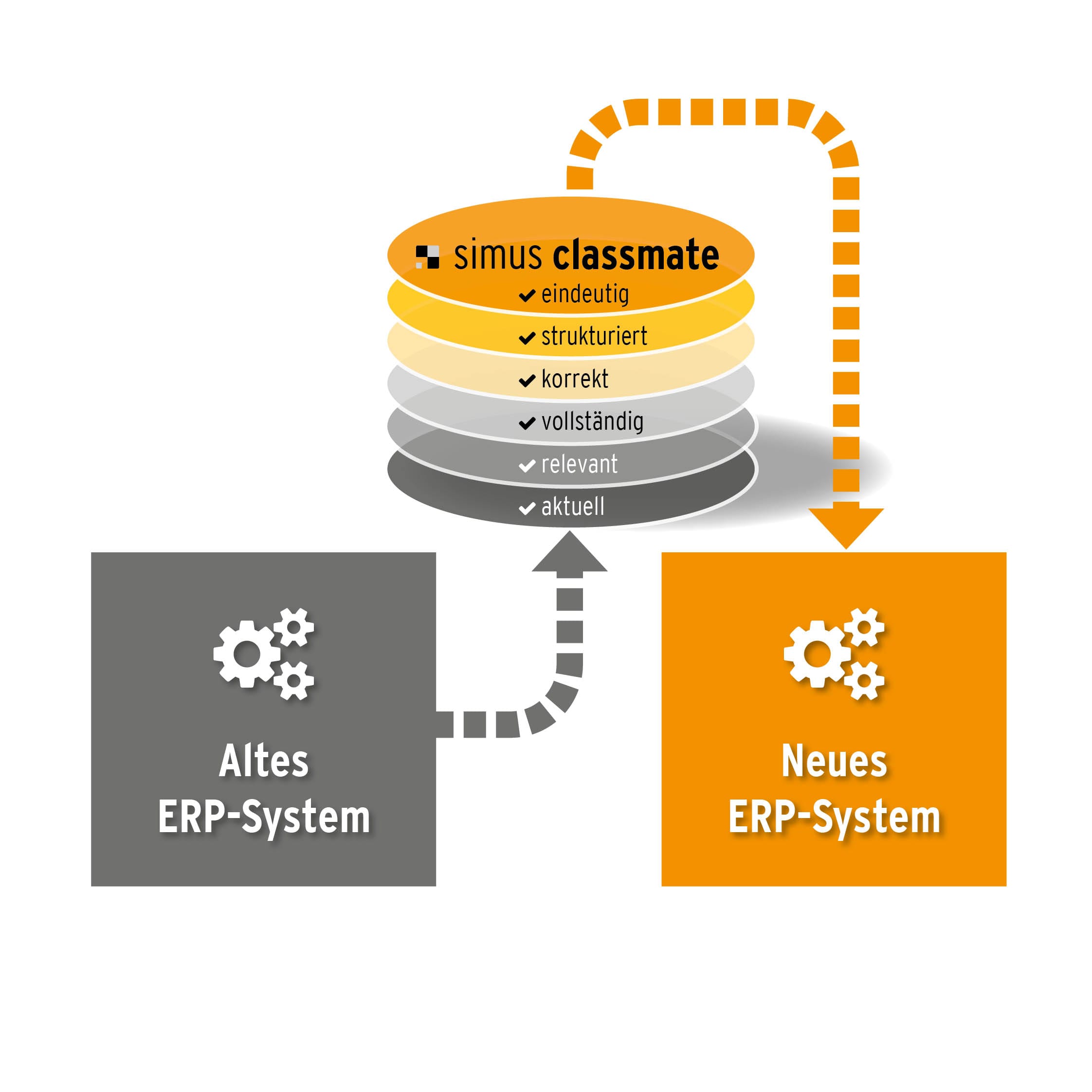

It was already clear at the time that the master data, which had previously been maintained in different forms and qualities, would have to be fundamentally cleaned up, supplemented and prepared for new automation and digitization requirements before the migration. Until then, the master data had been maintained decentrally by many authorized persons - poor retrievability and reuse as well as numerous duplicates were the result. Added to this were the requirements of the new ERP system, which the database could not meet anyway.

Master data cleanup

"We were looking for a master data specialist with in-depth SAP expertise to support us," reports Paul Lung, who is responsible for material master data and business partner data as SAP master data management team leader.

Simus Systems was selected from five providers. The main reasons were the method of individual but standardized classification offered by Simus, the Simus Classmate software tested in a preliminary project and the technical possibility of migrating the finished database directly into SAP.

"Although we weren't aware of many of the pitfalls of our project at the time, we wanted to tap into Simus Systems' SAP expertise," says Paul Lung. "In hindsight, this was certainly a good decision." Simus Systems had already demonstrated its proven approach and effective software in a preliminary project during the decision-making phase: Simus Classmate is used to automatically analyze extracted data from any source. Using the initially neutral rules for processing and optimization, the data is sorted, enriched and stored in an SQL database.

The results are then filtered and viewed using the Classmate Finder search engine to identify any errors, duplicates or inaccuracies. The data records found then do not have to be processed individually. Instead, the basic rules integrated in Simus Classmate are adapted to the individual customer so that the next optimization cycle delivers better results.

Individual classification

The classification project began at the start of 2022. A best-practice standard classification developed by Simus Systems was continuously adapted in workshops and consultations with the specialist departments. "This was an iterative process with changes to take many dependencies into account," reports Paul Lung. "Sometimes the standard fitted immediately - sometimes we had to adapt the classification to our specifications using the Simus methodology. In any case, it was good to be able to start from a base that we brought with us." Today, the individual classification is 99 percent complete. "All departments are satisfied," says Paul Lung. "We were able to take many dependencies into account now that we would otherwise have to deal with later in

S/4 Hana should have changed."

Define characteristics

The definition of the subject characteristics that describe the materials in the classes and the short texts that should provide an initial, catchy description of the material proved to be more complex. In order to bring real added value to the process, the short texts were to be fed automatically from the classes and characteristics - and in several languages. "Much of the necessary information was not contained in the master data. Finding the missing data was a major challenge, especially for the specialist departments," says Paul Lung. For the example of screws, not only information such as DIN, cylinder and dimensions is required, but also material and surface quality. How are high-strength screws 10.9, 8.8 or normal-strength screws 5.6 described? "Stainless steel screws are often specified in the food sector," says Paul Lung. "The production staff know this. But that's not enough for automatic warehouse management." Efficient and automated processes in the warehouse area are just as much a part of the company's goals as the configuration of products. To do this, the interfaces need considerably more data than was previously maintained.

Set up a Golden Client

In the meantime, the MDM team, together with the specialist departments, prepares the data largely independently using Simus Systems software. To this end, employees in design, purchasing, production and product management have 50 Classmate Finder licenses with read rights. "It's important to keep motivating people and to communicate the benefits of well-maintained data," says Paul Lung. "Sometimes you have to compromise, sometimes you have to be pushy - the key is communication."

The Simus Systems SQL database thus becomes the golden client, whose data is repeatedly transferred to the S/4 Hana test system via the Simus Classmate interface.

The program also provides the transfer features. "This would be much more time-consuming without the software, namely difficult manual work or individual programming," says Paul Lung. If data for a mandatory field is not available in S/4 Hana, the transfer would simply be aborted without the error being recognized. If you fill in other fields that are not mandatory fields, you would have to fill in all dependent fields to prevent an abort. In this way, errors and gaps in the data that still need to be closed are detected again and again. Of around 600,000 material master records in the old system, only around 15 percent are refined and migrated. The data in S/4 Hana is also checked and kept synchronized with Windchill PLM, the design department's product lifecycle management system, via an interface.

Perfect database

The short texts, which can only contain 40 characters in S/4 Hana, are now 80 percent defined. Some key users are working with the new data on a trial basis and have found that the required components and information can now be found very quickly and efficiently. The MDM team has set up new processes for material creation in which all relevant departments are involved in order to ensure the quality of the data. Hauser now has a treasure trove of data that saves time-consuming searches, duplicates and errors. In terms of quality and scope, it corresponds to the automation and digitalization tasks that the company intends to tackle in the coming years.

MDM must be carefully considered

"You have to invest a lot of time and thought in master data management, but it pays off immediately," says Paul Lung. "The excellent cooperation with the competent and friendly consultants from Simus Systems contributed a lot to the successful course of the project." The Simus Systems software will continue to be used for modification and maintenance work. Next, the MDM team will process the approximately 3,000 business partner data with a new module from Simus Systems. "We will have a solid database for the go-live with S/4 Hana by the autumn and were able to solve many challenges in the run-up to the migration that would otherwise have jeopardized a successful start."