JIT, agile & demand-driven

SCM, like many other IT tools, should not be an end in itself. Why is it only now that people are realizing that supply chain management must be designed on the basis of demand - demand-driven?

"The key motivating impetus for the development of the demand-driven SCM concept is a simple but far-reaching realization: our previous SCM approaches no longer meet the requirements under today's framework conditions - complexity, volatility and uncertainty - and the application of a central planning method from the 1960s"

Patrick Wolf, Partner at Camelot, explains at the beginning of the interview and continues:

"Almost all ERP or SCM/APS systems in industry today still have MRP processing logic from the 1960s at their core. This only works if demand is predicted very accurately, but this is simply impossible in today's world.

Therefore, instead of always trying to improve demand forecasting, the Demand-driven SCM concept addresses the root cause of supply chain problems first - namely, how we process and pass on variability and volatility in ERP/APS systems.

DDSCM, with its centerpiece - Demand-driven MRP - is a new approach to better manage variability in today's 'Digital Supply Chains'."

Necessary maturity level

The development of demand-driven SCM is comparable to machine learning: the idea and concept of neural networks has been around for many decades, but it is only current computer technology that makes it technically feasible in reality and not just on paper.

Suitable software solutions for Demand-driven SCM have also been lacking for a long time. Camelot's work is a pioneering achievement, which now enables the practical application of theoretical knowledge. Agile action not only includes understanding, analyzing and forecasting, but also consciously controlling the supply chain according to the actual customer needs.

The success of Demand-driven SCM is achieved through a clear shift away from trying to manage supply chain fluctuations through improved demand forecasting. The deliberate installation of "shock absorbers" in the form of inventory buffers at defined decoupling points in the supply chain ensures that fluctuations in customer demand are no longer passed on and amplified throughout the supply chain.

"Demand-driven enables the synchronization of the supply chain according to customer needs. The result is an optimal flow of information and material across all stations of the supply chain, i.e., from purchasing to production to distribution."

explains Christian Kroschl, also a partner at Camelot.

SCM can cover a wide horizon in terms of time, organization, and also physically: In practice, how do you synchronize SCM across many, even heterogeneous, stations so that the supply chain behaves in a demand-driven manner?

"This is ensured by the intelligent definition of decoupling points and an innovative approach that helps to control the stock level at these decoupling points"

defines Christian Kroschl.

SCM paradigm

Everything flows, everything is in balance - this is probably the perfect state for demand-driven SCM: How do you achieve this state technically and organizationally?

"Demand-driven is a new paradigm in supply chain management. Ergo, it is important to first anchor the 'thoughtware', i.e. the theoretical concepts and philosophy, in the company and the organization."

Patrick Wolf knows from his professional experience.

"So this is also primarily about business transformation, for which effective change management is needed. In our projects, we additionally support change management with training sessions conducted by our certified demand-driver trainers."

At Camelot, however, they also know that a "Thoughtware" is useless if it cannot be implemented with appropriate IT solutions. And Wolf emphasizes:

"What is needed are integrated extension solutions that map the Demand-driven SCM principles - something that did not exist for a long time. As a pioneer for SAP-based demand-driven SCM solutions, Camelot has been instrumental in making these extensions available for all SAP platforms today."

End-to-end

E2E is the new hype in ERP and CRM. Camelot now brings the E2E idea together with SCM.

"Supply chains as well as their management are by definition always to be understood E2E"

is how Christian Kroschl describes the Camelot approach.

"However, our experience has shown that, in practice, supply chains are often managed in individual silos due to complexity, variability and historical organizational development."

Camelot recognized early on that approaches and solutions were needed to help companies realize holistic supply chain management. Camelot partner Kroschl explains:

"We put these into practice in concrete supply chain integration projects. The approaches and project experiences have - already several years ago - resulted in the development of the Demand-driven Lean Supply Chain concept."

Accordingly, central elements for reducing complexity and variability are tactical configuration, active use of inventories in planning, and E2E synchronization of the supply chain, Camelot and Kroschl add:

"It was clear to us that forecasts - predictions of customer demand - should be the basis for supply chain configuration, but should not drive execution. Because of the alignment of concepts, we now work very closely with the Demand Driven Institute, the global authority on demand-driven MRP."

Demand-driven & SAP

"The currently available solutions can be easily integrated into any SAP system as an add-in"

Frank Arnold, Vice President at Camelot, describes the operational approach.

"Whether it's ERP/ECC 6.0, SAP SCM or S/4 Hana, it doesn't matter. There is also a demand-driven MRP solution for the modern SAP Integrated Business Platform, which Camelot has developed as a co-innovation with SAP."

But what do existing SAP customers say about demand-driven SCM?

"Demand-driven SCM is a key topic of concern for many of our customers"

Frank Arnold knows from his discussions with existing SAP customers. Companies have realized that the complexity and variability of today's global supply chains cannot be managed with the old MRP system world.

Arnold knows that customers have tried to remedy the situation with tools they developed themselves, but haven't gotten very far.

"Accordingly, a new concept is being sought with corresponding IT solutions that can be flexibly adapted to the respective customer situation"

Vice President Arnold defines the current state.

What SAP architecture and components are required to implement demand-driven SCM for an existing SAP customer? Frank Arnold explains that Camelot's understanding of a holistic SCM solution includes the following:

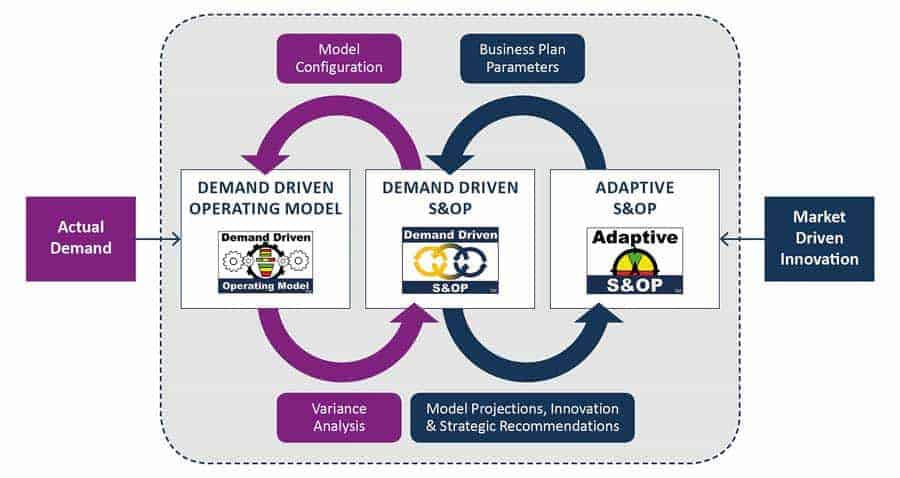

In addition to the main components Demand-driven MRP and Demand-driven Rhythm Wheel Planning, an approach for smoothed production planning (production leveling), also extensions such as for Demand-driven Sales and Operations Planning, strategic AI-based segmentation and configuration, as well as machine learning algorithms in production leveling. Arnold:

"In terms of SAP solutions, Demand-driven MRP is available today on the S/4 Hana, SAP SCM and SAP Integrated Business Planning platforms through standard solutions or enhancements from SAP and Camelot.

Production Leveling is available as an enhancement for SAP APO PP/DS and S/4 Hana Advanced Planning exclusively from Camelot." Camelot develops the aforementioned enhancements based on the SAP Cloud Platform (SCP) and SAP Leonardo.

Added value in business management

"With DDSCM, it is possible to get a handle on the variability that causes excessive inventories and long delivery times"

explains Patrick Wolf in an E-3 interview.

In turn, mastering variability leads to immense business and financial benefits. For companies that have implemented demand-driven SCM, Camelot has seen performance improvements - across industries - averaging 31 percent less inventory, 22 percent lead time reduction, significant service level improvements, and double-digit efficiency gains.

Is there a connection between demand-driven MRP and demand-driven SCM?

"Demand-driven MRP is an approach specifically for material requirements planning and the core of Demand-driven SCM. However, from Camelot's point of view, Demand-driven Supply Chain Management also includes a corresponding concept for production planning, Demand-driven Rhythm Wheel Planning, as well as additional extensions such as, above all, for Sales and Operations Planning."

Patrick Wolf adds to the previous statements.

At Sapphire this year, SAP CEO Bill McDermott presented the new CRM product C/4 Hana. In this CRM initiative, SAP speaks of E2E and sees CRM as the starting point and ERP as the end point.

Where does it say demand-driven SCM and MRP?

Christian Kroschl:

"In this definition, CRM is used synonymously for demand generation and ERP for fulfillment or execution. Demand-driven SCM is thus to be understood as a link that takes up the "demand" and transfers realistic, demand-based planning to the ERP for execution.

Of course, seamless real-time reconciliation between systems is the basis for optimal planning and execution. SAP is of course ideally positioned here with its highly integrated solution portfolio."

And to what extent does Camelot collaborate with SAP on Demand-driven SCM?

"As a pioneer for SAP-based Demand-driven SCM solutions, Camelot is working very closely with SAP here. An example of the collaboration is the co-innovation of Demand-driven MRP for SAP Integrated Business Planning, the first ever extension solution for SAP Integrated Business Planning."

confirms Frank Arnold.

Everything Demand-driven

In the future, will every SAP three-letter term be preceded by a "DD" for demand-driven? "In theory, yes," says Frank Arnold in an interview with E-3 Editor-in-Chief Färbinger:

"However, the term demand-driven was explicitly created to express the move away from forecast-based planning of value creation to an absolute focus on specific customer and market needs.

This implies a paradigm shift in SCM that we do not see in the same way in CRM or marketing. Here, the focus is on the customer and the demand generation by definition."

Since ERP systems have evolved from the classic MRP-based PPS systems, and even today the MRP planning approach forms the basis of every ERP system, one could of course coin the term demand-driven ERP or DDERP here, says Arnold.

"An example of this would be S/4 Hana, which has been expanded to include demand-driven MRP functionality. But we believe that the number of new abbreviations will cause sufficient confusion even as it is."

he admits to a linguistic challenge in the new SCM world as well.

Stability & Efficiency

Where did the highest ROI result in the operational implementation?

"It always depends on the customer situation to what extent and in what timeframe an ROI is achieved"

explains Christian Kroschl.

"Our experience is that in all organizations, ROI is realized in less than two years!"

What are the user insights?

"The nervousness in the entire system almost completely disappears. All fluctuations in the supply chain are managed efficiently. The most noticeable change is in the planners' day-to-day work."

Patrick Wolf knows from many satisfied customer statements.

Instead of "firefighting missions" and the permanent rescheduling of orders, SAP existing customers can now concentrate on their actual task of planning exceptions and difficult products.

"In addition to the 'hard facts' already described in the form of business and financial benefits, customers also feel the following positive changes: simplified business processes, fewer conflicting goals and friction losses within the company, and of course: more satisfied customers."

Wolf explains and adds:

"Our experience is that all business units involved in demand-driven SCM projects, including the CFO, are enthusiastic about this intuitive and understandable concept."