Interactive Virtual Reality in the CPQ Process

CAD data are the basic framework. The variant configuration is the individual offer to the customer. Added to this are good relationship management and appropriate pricing.

Until an ERP system is a satisfactory quotation and sales system, it needs many additions and adaptations. SAP partner SAE has untied this knot.

The growth and profit leaps of many manufacturing companies from various industries are largely due to the fact that products or entire product system solutions are finding buyers in increasingly varied forms. This development will not only continue, but will also be significantly intensified by the use of various digitization options.

Process-integrated and virtual configuration tools that expand the CPQ (Configure Price Quote) software used as needed and offer increased potential for use and benefit in sales, but also in service - see the following discussion - will represent the standard in the future in connection with Sales 4.0. In addition, sophisticated product management must of course also be ensured in the context of ever greater digitization.

The speed of innovation in Configure Price Quote software has always been high. Numerous medium sized enterprises and large companies benefit from the constant innovations and further developments.

The focus of configure-price-quote software is on the profitable use of real process-integrated optical configurators with real-time interactions. Here, feature evaluations take place directly on the concrete model using virtual reality technologies.

Product configurators are used in a variety of ways, for example in online stores in the B2C sector as well as in B2B online portals of companies. However, various solution approaches have so far been limited to a rather low level and are sometimes afflicted with considerable media disruptions.

The following roundtable discussion illuminates the potential applications and looks beyond the surface to provide ideas and perspectives for an innovative approach to 3D variant configuration developed by SAE.

Peter Färbinger: Almost everyone knows a configurator, at least all those who have ever bought a car. If you set something wrong, the software "screams", moreover, a price tag always runs along on the page as well.

My question to the round: Do you need something like this in the industry at machine and tool manufacturers? In industry, you have experts sitting in front of you, and when they see a material number, they immediately know what fits it. Do you need visual support here as well?

Ben Herrmann: In industry in general, and especially in mechanical and plant engineering, it is important to have visualization. Here, configurability, i.e. the selection of the various elements that I put together, is a prerequisite.

The customer no longer asks for a direct product, but for a holistic service, such as a business case for energy generation at GE Power.

With cars, this is still relatively trivial. With plants, such as those planned at GE Power, it is no longer so trivial. Industrial products are complex, have a wide range of requirements, such as legal requirements, and thus a large number of possible configurations to map all these requirements.

Hence the high level of investment in the quotation and order processing departments and the technologies required there. Without modern, innovative IT support, it will no longer be possible in the future to offer technically sophisticated products and systems in a timely and cost-efficient manner.

If I can already tell in the initial budget phase - in the quotation phase - which solutions I will offer a customer, I have saved both sides, seller and buyer, a lot of effort. So in mechanical and plant engineering, an easy-to-use interactive 3D visualization is definitely needed as a support.

Färbinger: Is the visualization of the variant configuration the exit strategy for being able to master complexity at all, because humans apparently can no longer master it?

Frank Niemann: The applications will remain complex and they will become even more complex because the requirements will also increase. I think B2C and B2B are separate markets, but they influence each other.

The expectation today is that a complex machine can be configured visually, just like an Audi on the vendor's website. The complexity at the customer interface is added to the existing complexity at the back end.

We're talking about the digital consumer experience, which is also spreading strongly in the B2B sector. There is certainly a lot of catching up to do here. We are currently seeing a major trend toward B2B e-commerce.

So: We had B2C and it is also running. We actually already had B2B, too, in the simplest case in the form of EDI, Electronic Data Interchange. Now we have B2B e-commerce. A digital sales channel is emerging and visual variant configuration or CPQ are certainly part of it.

Färbinger: The user then configures complex machines himself and puts them in his shopping cart?

Niemann: That would be the wish. The batch size of one is certainly one of the things we will see more and more often, precisely also in mechanical and plant engineering. Perhaps interaction with a sales representative is no longer necessary.

But the configured machine is only one part of B2B e-commerce. For example, services and spare parts are a huge market for German industry. Here, too, I have to configure, there will also be automated and self-service variant configuration.

Färbinger: How do you see the changed role of sales, who perhaps used to type the order with a typewriter and now interactively performs variant configuration in front of a screen? Has the role changed, will it change, in which direction is it going?

Susanne Henkel: The role has definitely changed. B2B products are now highly individualized. Machine builders have to respond much more strongly to customers' individual needs than in the past.

This means increasing complexity for sales. The sales employee must be empowered to carry out the individualization of the offer himself, because the individual and visual configuration means that the offer is accepted more quickly.

The problem was that the design departments, which had to convert the quotation into a CAD model, were often completely overwhelmed in terms of time. The challenge is to enable sales to map this pre-CAD phase themselves.

In this way, he can immediately show the customer that this is his individual product, his plant. This is how an individual product solution created by the customer is actually created.

Färbinger: So one challenge is to optimize the sales process?

Handle: The sales department comes with a requirement from the customer, now it is implemented CAD-wise in the technology, then it goes back to the customer, who says, I didn't really imagine it like that.

The customer changes the configuration, which then has to go back to the technology - and so on: ping-pong. What we have now achieved is to carry out the configuration independently, visually, interactively and directly on site, to implement the spatial dimensions, the functions, the characteristics of the equipment and systems directly in discussion with the customer.

This is the new role of sales. Ultimately, everything is measured by the time factor. In addition to the shorter throughput times that can thus be achieved, we relieve the design department in the process of order acquisition - which is probably one of the most strategically important processes in the company.

We don't know at the beginning whether it will be an order, but we also don't create internal costs in the design department.

Färbinger: Is that right?

David Sappl: These are exactly the problems we have been struggling with. Customers have certain requirements. As a designer, I get the requirements from the salesperson, then I start, make my plans, and after two weeks I hand in the plan.

Then the customer realizes, there we are too close to the property line, the positioning of the transformers must be repositioned due to a change in the location of the connecting line, and so on.

A configurator in sales is the single source of truth, that is, the only source on which we build. If the salesperson configures the offer with the customer visually and interactively, then I receive very accurate and precise information in order planning.

I can immediately see how, for example, the building with the motors is to be positioned on the property and can automatically calculate or derive all the connection lines using the configuration.

Nothing then stands in the way of error-free, efficient order confirmation and order processing.

Färbinger: Mr. Schaarschmidt, we described your solution in the E-3 Cover Story April 2018. Listening to this, the advantage of your solution is that there is an end-to-end situation that goes back and forth seamlessly, so I don't run into these dead ends and spend two weeks constructing what I can then throw in the trash.

Erich Schaarschmidt: That is exactly what our goal has always been. We have been involved in the CPQ process for many years and have witnessed how time-consuming it is to implement complex machine and plant solutions.

"State of the art" is a complex coordination and synchronization between customer, sales, design/development and controlling. This is the daily routine in technical machinery and especially in plant engineering.

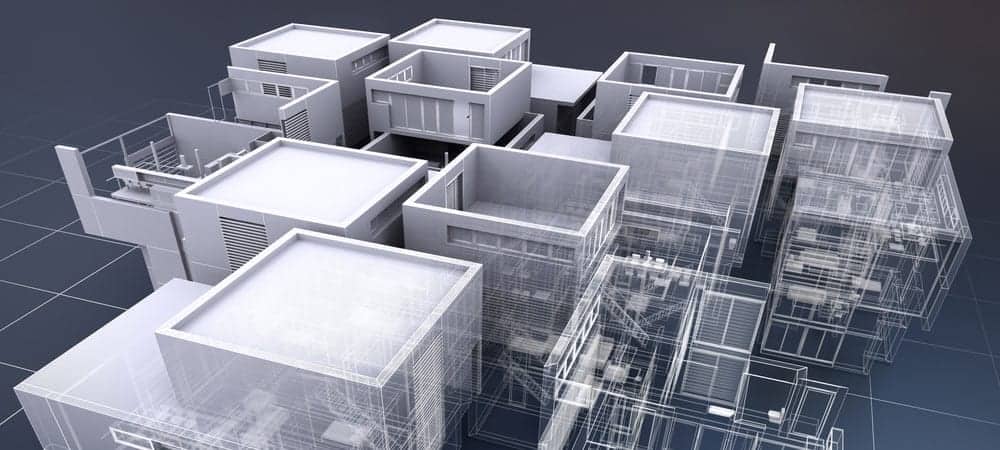

Plant engineering means assembling a solution from countless components. SAE reduces the enormous effort through interactive 3D modeling including SAP integration.

Because we are an SAP partner, we naturally want to use as much data as possible. Built into our solution is that the design is offered with the right prices and of course the right texts are available.

Often people don't think about what a gold treasure the LO-VC, the SAP variant configuration, is. Through our solution, we can make the LO-VC available to colleagues out in sales, so that sales can also live exactly this end-to-end solution with this treasure trove of data.

Färbinger: That all sounds very logical. Why hasn't such a solution been around for ten years?

Niemann: So CPQ, Configure-Price-Quote software, has been around for quite a long time.

Färbinger: Where is the secret?

Schaarschmidt: We have a technical past and we have always been SAP solution providers. SAE has been involved with configurators for more than 20 years.

The logics and methods of SAP-LO-VC provide a flexible tool for ordering and thus avoiding errors. If a variant model is now combined with the associated 3D model data, a unique application is created.

By the way, CAD automation has always been a specialty of SAE. It was really only a matter of time that, as technologies advanced, we would develop and provide our own CAD application as a digital twin for sales. I want to see what I configure and I want to be able to operate it easily.

Niemann: They focused precisely on this issue, the last mile, so to speak. You have not questioned something that is already established. They have "closed" the last mile to sales, or in a broader sense, to the customer or perhaps even the sales partner. We're talking about CPQ today because the big IT vendors can't invent it all themselves.

Herrmann: I believe that the world has also changed. Against this backdrop, two buzzwords are important to me: simplification and digitization.

Simplification in this context means that everyone wants things to be simple. We are used to this in the digital age, and the second word is already included: We are talking about real digitization, automation - that many things are simpler.

It's not that you oppose technologies, but you try to go along with them. This mindset change that has taken place is the real driver. And so it is that the SAE company has gone ahead here - from the mindset of inventing a 3D variant configurator.

Schaarschmidt: I spoke to the CEO of a large company last week and he said the exact same thing.

In purchasing, we are getting more and more impetus from the younger generation, and they are no longer satisfied with five pages of prefabricated text describing a machine - they want to see it.

They also want to be able to simulate how the plant works. Now, of course, it also fits the mindset that this visualization and simulation is technically possible via web browser.

Now you can see in the SAE cloud application how I simulate the production process, for example, that the production cycle is correct, that the ROI calculation fits based on the processes. When the robot bends a part, for example, the process can be shown in a 3D simulation, and of course you can score points with that.

Handle: It is important to differentiate between rigid 3D visualization and interactive 3D modeling or design and simulation. 3D visualization or 3D configuration exists.

But a lot of it is just isolated solutions. I can configure with 3D, but the results are not based on the SAP LO VC. How does that help me? With our SAE Interactive Motion Engine solution, we have created an end-to-end solution.

We pull the data from SAP, take the CAD data and combine it with our Interactive Motion Engine IME. Sales configures, pushes the button and gets a complete quote including a simulation with high-quality graphics.

This can lead directly to service manuals, instructions or marketing campaigns. The prospective customer receives his offer and sees exactly what his configuration looks like.

Furthermore, the individual 3D model is fully dynamically customizable. That makes the difference and that is the added value. This is the only way I can relieve the "CAD departments".

Färbinger: This simplification actually results from the integrated system. For sales, but also for the customer, this results in a new role model, a different challenge, doesn't it?

Niemann: This also has organizational implications, when I no longer work sequentially, but interaction becomes possible. For me, this results in an information hub on which design, development, sales, marketing and service can exchange information.

Then it may become easier to make organizational changes instead of saying you need to get together often enough and talk to each other more and you'll be fine.

Herrmann: It gives me a communication and networking tool. Sales will have to look at itself differently. At the location in Germany, there is this technical sales, but in the global market, it looks different.

With the solution, I can better inform the customer, even if he has less detailed knowledge. Many people today no longer want to know every detail.

You need to understand it simply, and that very simplicity is the most important thing. There is no way around interactive 3D modeling.

Schaarschmidt: We have two customers who get thank you emails from their sales offices located around the world. Who gets thank you emails from their sales force? Because now they can sell sensibly and perhaps more liberated - without the worry, hopefully I haven't made a mistake - our SAE IME is paying attention.

Herrmann: It is good to have a tool with which you can plan end-to-end, from external customers, sales into internal customers. The last instance is production and service, which must be considered.

Only through a valid configuration can I also say whether buildability and feasibility are given. Nevertheless, one insists on variant reduction, otherwise I reinvent everything.

We talk about configuration, but looking at the cost is important! That should be seen again just about such a tool: What does such a configuration cost me?

The advantages are, on the one hand, Prediction, I can anticipate what the customer wants, and on the other hand, Guidance, I show the customer how the product interacts in his environment.

He then says, this doesn't fit and I need something else, which he has to order again in the post-process. This results in unbelievable costs that disappear into overhead pools that can no longer be verified.

These are the hidden complexity costs, as it is called in technical jargon. This cost issue is one of the most important challenges for companies.

Färbinger: Are we having a technical or business discussion here?

Niemann: The one conditions the other. You can no longer separate the two. Business needs IT, and when we talk about costs: How long can a sales expert spend with a customer, with an offer?

In a high-wage country like Germany, where there is a shortage of skilled workers, human and time resources are very limited. So any kind of automation is naturally a benefit for the company.

Of course, in the end we are talking about technology, but the business lever is increasingly being considered, which is why the relevance of IT solutions is then also increasing.

Herrmann: The uncertainty arises from the fact that customers are difficult to assess. I go into a conversation with the customer and have the order processing chain in front of me: from initial contact to order delivery.

The second, subsequent part is the service, which is often sold along with it. I sell the customer a business case. The question arises: Am I really offering just the robot arm or an entire production facility?

Handle: There is a risk that a pure sales configurator is not technology-based and, for example, buildability is not guaranteed. Consistency is essential.

I can then also make this customized 3D model available to the service department. This really brings added value: consistency based on the set of rules.

I get it back into SAP at the push of a button and I can make this data, these models, and images and movies available to everyone. The customer experience, the shopping experience that is created there, is convincing for the customer.

Herrmann: This is an important point. This service area in particular is often forgotten. The service technician stands outside in front of the machine and doesn't know what the thing looks like. A digital twin for service is created from the 3D model.

Handle: Exactly. The service technician is not presented with a general model, but actually sees the customer's machine. And then, of course, he also sees which component needs to be replaced.

Niemann: It's a different way of experiencing the product. When I go to a website today, the first thing I see is a video: Visualization. I will have to create that tangibility.

Färbinger: But is only beautiful not too little?

Niemann: I would like to add one more point that helps bring out this pervasiveness of data: I learn much more about my customers.

Who wants what constructed and how? From which region, in which customer size is the demand? What are features that are always modified? This feedback from the customer interface back into product management also enables consistent data management.

Dyer: You have to make people aware of the treasure trove of data that I have, that I'm actually using it.

Niemann: That is something I can only emphasize. Qualification and education are a huge issue in digitization. It has nothing to do with automating everything and then not actually needing people anymore; instead, I have to involve people, but to do that I have to qualify them.

I am convinced that things can also be changed in a company, not from above, but ultimately by providing and letting people participate.

Handle: Because our system is interactive and actually self-explanatory, there is no training in the sense of "I have to explain the tool". The user trains himself automatically through operation.