X-ray machine for business

![[shutterstock.com:307511156, Watcharakul Gongun]](https://e3mag.com/wp-content/uploads/2017/03/roentgen.jpg)

Process mining technology uses companies' IT data to reconstruct and visualize processes. Any process in companies of any size and industry can be optimized - whether purchasing, production, sales, logistics or customer service.

What can process mining do?

Celonis Process Mining merges the individual process steps stored in different IT systems and analyzes actual processes in companies automatically and end-to-end.

It enables complete transparency at any point in time and in any depth. Instead of investing a lot of time in problem analysis, companies can use process mining to focus directly on measures to increase operational efficiency. This is because they can see at a glance why orders take more time than planned or why there are delivery delays and detours in purchasing.

The variety and meaningfulness of the insights gained from process data analysis are often very surprising for customers. Many users of the software already suspect that certain processes in their company are not running optimally - but the core problems do not always lie where they were initially suspected.

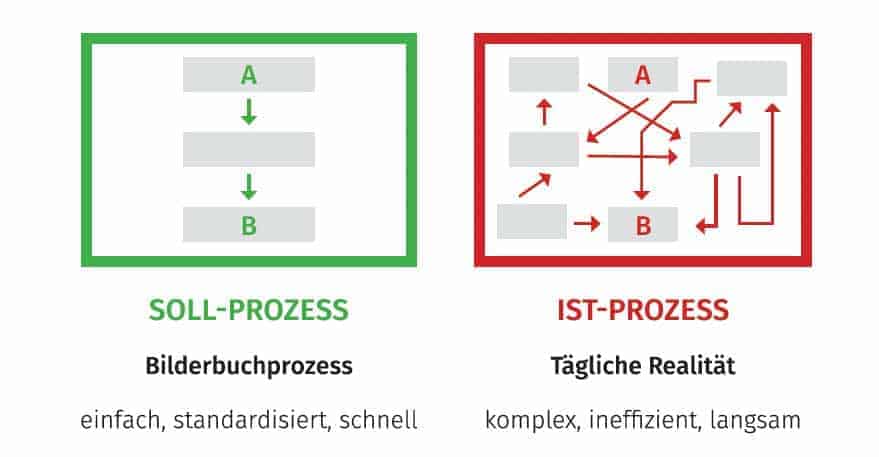

Celonis Process Mining shows at a glance where the actual process deviates from the target process, where the causes are and how these deviations affect the overall efficiency of the company.

Users typically pursue one of the following goals with process mining: Identify best practices, reduce process costs, shorten lead times, increase process quality, standardize processes, or improve compliance in processes.

How do SAP users benefit?

A typical SAP system contains valuable data about a company's operating processes - accordingly, process mining is a strategically relevant and interesting topic, especially for SAP users. This is because evaluating the information has often been complicated up to now.

Not with Celonis Process Mining: Due to years of experience with SAP environments, the connection of SAP systems to Celonis is almost entirely automated. The technology is extremely easy to set up and use.

Customers can start working with a productive process mining solution in a very short time and quickly realize results and process improvements.

Celonis uses the power of Hana to process and analyze its customers' sometimes very large data volumes in real time.

The example of Siemens shows just how comprehensive this can be: Here, a good 30 terabytes of data are analyzed on Hana. Interactive performance and processing in a matter of seconds are prerequisites for process mining. Even for complex scenarios with a large number of systems, Hana can be used to create a powerful, central data platform.