IoT and E2E

The company TiSC is the current answer to a digital transformation driven by Industry 4.0, IoT, Suite on Hana, S/4 and ultimately the Hana Cloud Platform. The company is not even a year young.

However, some of the acting persons have decades of experience in the ERP business and the SAP community: Michael Schuster, CEO of TiSC AG and co-founder of GIB, Dr. Myriam Jahn, TiSC board member, Nadine Rahman, TiSC board member, Markus Fresslé, TiSC board member and Qosit company founder, and Dr. Thomas May, TiSC board member and IFM managing director.

TiSC stands for end-to-end processes (E2E) in the IoT and Industry 4.0 sector.

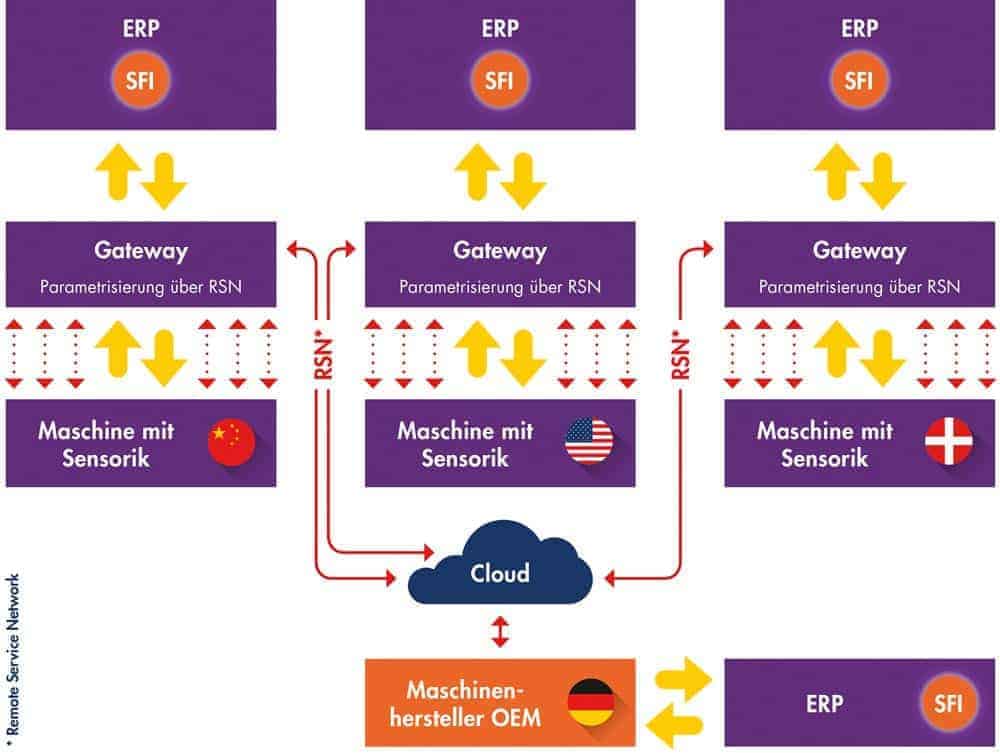

"The journey from sensor to ERP will soon be a tangible reality for our customers."

The topics are thus dictated by sensor technology, automation, and logistics and scheduling. The basis will be both on-premise and cloud computing, which will be primarily realized by SAP's Hana Cloud Platform.

TiSC founding member and board chairman Michael Schuster emphasizes on page 60 of this E-3 cover story:

"GIB's core business is and remains the dispo cockpit. The greatest priority is to continue to develop and expand this business."

The Internet of Things with the expected millions of sensors will transform many theoretical business processes and models in production and logistics into practice: The tools for digital transformation are now emerging from SAP partners and SAP itself.

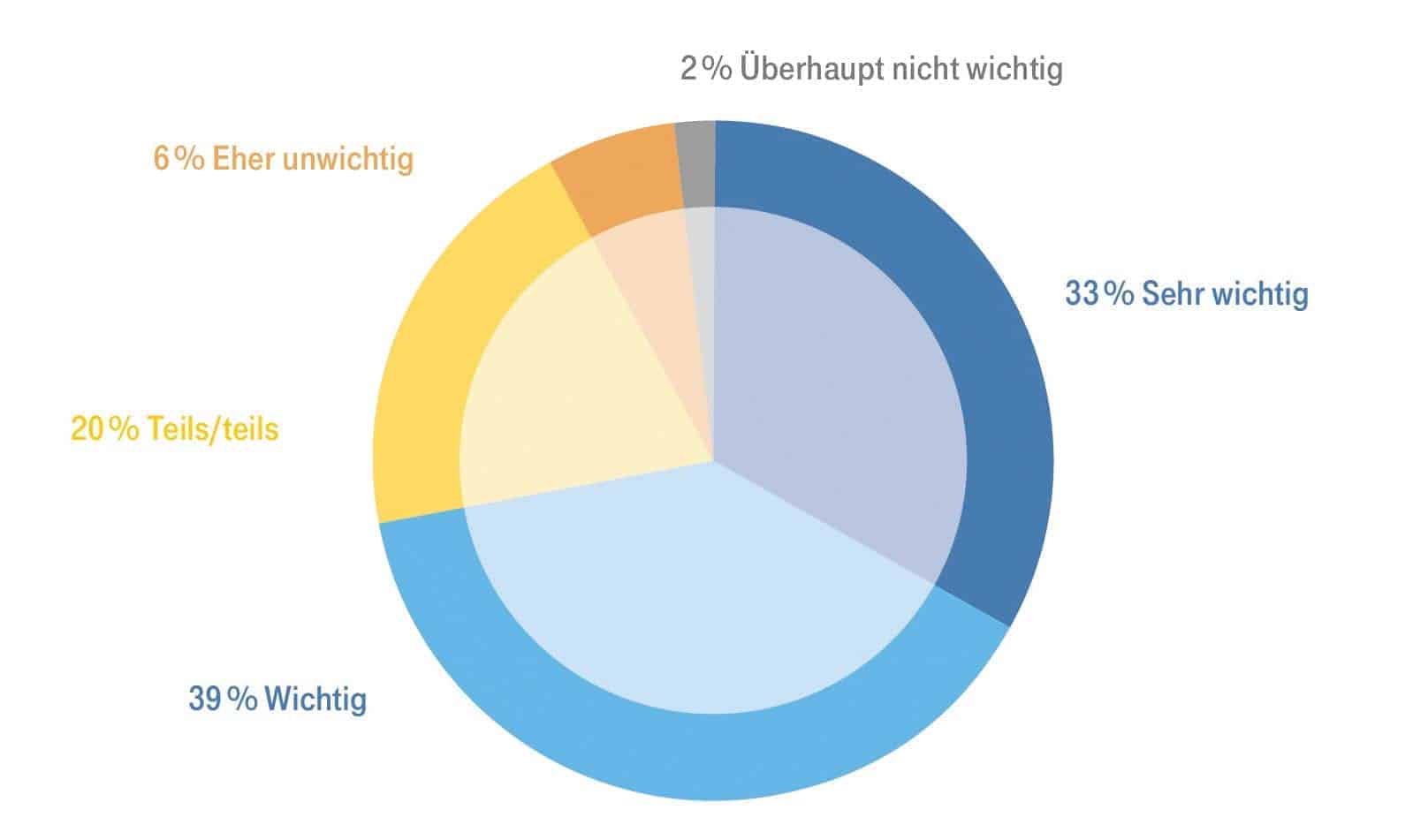

Although the pace of implementation varies by industry and company size, almost three quarters of the companies surveyed by Telekom Deutschland at the end of 2016 rate digitization as significant for their company and industry. Almost half are already implementing individual transformation projects, while 27 percent have an overarching digitization strategy.

SMEs are aware of the benefits: 53 percent expect more innovation, 54 percent want to tap into new customers and markets.

"The results show that SMEs are already much further ahead with digitization than is often assumed.

A recipe for success for medium-sized companies has always been to accept new challenges and adapt flexibly. This is demonstrated, for example, by the early automation in the manufacturing industry, which is dominated by medium-sized companies.

Most companies have also successfully mastered globalization. So for them, digitization is 'just' another stage of change."

The TiSC AG group of companies (see also page 60) stands for automation and internationalization.

Automation & Cybernetics

Sensors and the vision of an E2E solution from the factory via the warehouse into the ERP - i.e., the connection of blue collar workers and white collar workers - are not an end in themselves, but an expression of a necessary automation. Production, logistics, SCM and ERP need a new cybernetics.

This term is derived from ancient Greek and stands for the art of steering, i.e. the mastery and control of complex processes.

In ancient Greece, it was considered a high art to bring a ship safely through the storm into port without damage or loss.

Wikipedia:

"Cybernetics, according to its founder Norbert Wiener, is the science of controlling and regulating machines, living organisms, and social organizations, and has also been described by the formula 'the art of control.'

The term as such was adopted into the German language in the middle of the 20th century, following the example of the English cybernetics 'control techniques'.

The English term, in turn, is a word of art, formed from the substantivized Greek adjective κυβερνητικός 'helmsman,' which is derived from the corresponding subjectives κυβερνήτης 'helmsman' and κυβέρνησις 'leadership,' 'rule.'"

Digitization is a matter for the boss

Based on their experience with automation, industrial companies are among the digital pioneers, according to the Telekom Germany Study 2016. They are followed by professional service providers, who can even already offer their customers digital products.

In the construction industry, the desire for mobile data access is an important motivator. Although the retail sector in particular is under considerable competitive pressure from major players such as Amazon, Zalando and others, it is not yet able to catch up with the pacesetting sectors of industry or service providers.

Digitization is a matter for the boss: The Telekom study also shows that there are still various barriers. For example, 41 percent of respondents fear high investment costs; 36 percent worry about additional IT security risks.

"The issue of investment costs alone makes decisions about digitization a matter for the boss. In addition, business success will increasingly correlate with the degree of implementation in the future. Therefore, managing directors must be the drivers"

The index already shows a clear correlation between transformation and profitability among the top digitalizers.

In 63 percent of the companies surveyed, digitization is a top priority, with the IT department also acting as a strong driver - especially in larger companies.

The pace of digital transformation varies greatly. This is because not all aspects of digitization are equally interesting for all companies.

A company with three employees, for example, does not necessarily need a collaboration platform - the exchange works at least as well over (analog) coffee.

But another, perhaps more important reason is that companies need to learn much more from and among each other.

In 63 percent of the companies surveyed by Telekom Deutschland, digitization is a matter for the boss. And it has to be.

Digital transformation is not just any new software update. It is a strategic realignment, indeed a new way of thinking. The entrepreneur, the CEO must drive it, otherwise it will be very difficult.

The management is responsible for the helmsmanship. In addition to consolidation, harmonization and automation, cybernetics is now added.

TiSC has the hardware, software and brainware to implement automation and cybernetics in production and logistics.

Continuous digitization of new business processes and models seems to be important here: According to an IDC study commissioned by SAP, SMEs pay particular attention to uninterrupted business operations when introducing new technologies.

In return, companies accept delayed benefits: Only one-third of decision-makers see improved processes in the short term as the main aspect of investing in new technologies.

Around half of SMEs in Germany prefer to implement new solutions gradually, but as simply as possible. By comparison, only ten percent of SMEs opt for more extensive projects with rapid process improvements.

Two-fifths favor a mix of short- and long-term solutions.

"The study shows that German SMEs are looking for new solutions that can be used to drive forward the digital transformation.

The companies rely on very well thought-out solution models that tend to achieve long-term and sustainable effects.

Anyone who wants to gain a competitive advantage today must invest in the existing IT infrastructure. This is the only way for medium-sized companies to remain competitive with large corporations.

Integrated Business Planning

IoT and Industrie 4.0 can only be successfully implemented in a digitized E2E process. And IoT/E2E also includes integrated planning.

"Here, we must clearly emphasize the topic of IBP. However, not necessarily in the form of SAP's IBP solution, but rather in the awareness of our customers and interested parties with regard to the relevance of integrated planning.

For years, we have been selling our Dispo-Cockpit, a suite for optimizing logistics processes along the entire value chain.

Starting with sales planning, through inventory planning, to production planning. However, our customers tended to use the individual modules to plan sales and, independently, inventory and production. So rather the optimization in silos.

SAP's new solution, IBP, creates a deep understanding of breaking down silos and the need for integrated planning across departments.

This clearly benefits us and is sure to be the megatrend of the next few years."

However, around 60 percent of DACH companies assess the strategic planning of the digital agenda as a very multifaceted task that requires a wide range of competencies that cannot be economically mapped within their own company.

This is the result of the CSC study "Digital Agenda 2020", which was conducted in Germany, Austria and Switzerland in June 2016.

TiSC is therefore on the right track: Against this backdrop, when it comes to cooperation with specialized service providers, managers see themselves quite well positioned for digitization projects.

Only just under one in five lacks in-house contacts as an interface for collaborating with external partners.

However, the situation in Austria is an exception. Here, around one in three managers complains that there is a lack of employees for external collaborations.

Claus Schünemann, Chairman of the Management Board of CSC in Germany:

"The pace of digital competition in Germany, Austria and Switzerland demands consistent implementation of the digital agenda in companies"

"As practice shows, this requires a close interplay of internal and external expertise in order to quickly tap the digital opportunities for one's own business model."

How will TiSC interact with the companies GIB, Qosit and IFM? Are there synergies?

"Here, three different companies have come together at one table, each of which is an absolute specialist in its own subject area"

explains Björn Dunkel in an interview with E-3 Editor-in-Chief Peter Färbinger.

"The synergies are almost endless and in the end lead to a unique constellation for our customers.

A holistic solution from the sensor to the infrastructure to SAP, and all from a single source".

adds the GIB managing director.

At 52 percent, more than half of the company bosses believe that their company will probably no longer exist in its current form in five years' time.

The reason for this is the consequences of the digital revolution. This is one result of a global study by Fujitsu.

While almost all of them are aware that their company is already influenced by digitization and that this will not change anytime soon, 92 percent believe that they still need to adapt to it much better.

After all, two-thirds are convinced that their respective industry will change decisively by 2021.

"Over the past ten years, we have built GIB into a pseudonym for software solutions for optimizing logistics processes based on SAP that are suitable for medium-sized companies"

Björn Dunkel emphasizes.

"The GIB brand will of course continue to exist and will be further strengthened. We have also been a partner since 2005 with SAP based on NetWeaver as our development platform.

It is possible that the partner status of a GIB will change in the coming years, but GIB is and will remain completely independent, even in relation to its partners.

In five years' time, I see GIB established in many countries around the world selling solutions that provide a not insignificant proportion of sensor-controlled services in the predictive maintenance and store floor integration environment in addition to the classic optimization of logistics processes."

IoT & Industry 4.0

SAP has unveiled a program for its portfolio around Internet of Things solutions to help customers enter the new world of smart devices, connect people and processes, and realize clear business value.

The SAP Leonardo IoT portfolio bundles Big Data applications and connectivity into a cross-business unit package offering with application scenarios for connected products, assets, and infrastructure to fleets, markets, and people.

Recently, SAP had already announced that it would invest two billion euros in IoT over the next five years. TiSC is therefore on the right track for the SAP community.

The new company design is exactly in line with the megatrend set by SAP.

Dr. Tanja Rückert' subtitle, Executive Vice President for Digital Assets & IoT at SAP:

"The 'Things to Outcomes' vision is about new business processes such as Industry 4.0, new business models, and new work and life models"

"With SAP Leonardo, on the one hand, we connect things with business processes, making them immediate and proactive. On the other hand, we also bring things and people together so that they can work more efficiently thanks to extended intelligence and autonomous systems, With the SAP Leonardo IoT portfolio, we are delivering on our promise to offer customers special added value through IoT innovations."

How well positioned is SAP in the IoT and Industry 4.0 environment?

Björn Dunkel comments:

"With the Hana Cloud Platform, the way is paved for all conceivable solutions in the field of Industry 4.0 and IoT, but a large proportion of solutions will also need to be developed by partners on this platform in order to be able to offer solutions suitable for SMEs. In other words, a playground for partners like GIB. However, not every Industre 4.0 and IoT solution will have to take the detour via HCP. We will also create solutions in the core based on SAP ERP and S/4!"

The new IoT program is designed to help companies identify and validate use cases faster. They will be advised by business unit and industry experts from SAP and the partners such as TiSC.

The program is composed of several phases and uses the Design Thinking method (presented at GIB SuccessDays 2016, among other events) to align IoT innovations with customers' strategies and goals - in feasible steps and with clear value creation.