When manufacturers become dealers

In the fashion and lifestyle industry in particular, customers have long since become accustomed to manufacturers becoming retailers and maintaining their own flagship stores, selling their goods directly on the Internet, and opening up additional sales outlets and opportunities in parallel to traditional retail.

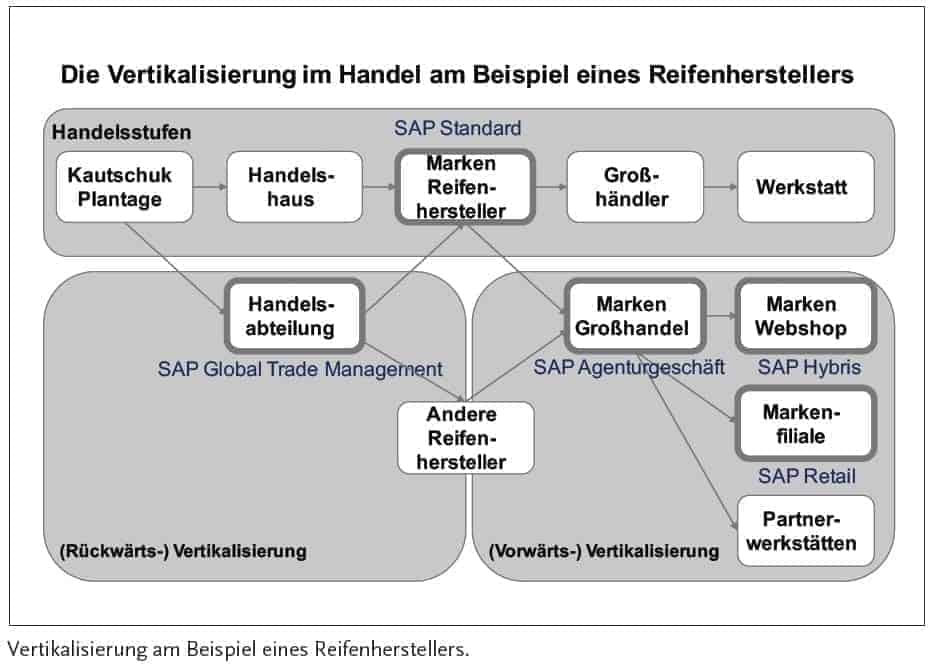

In addition to this strategy, which experts describe as "forward verticalization," many manufacturers are now also discovering the verticalization path backwards: Numerous production companies are reinventing themselves, repositioning themselves in purchasing and becoming active as raw material or material traders themselves.

The boundary between manufacturing and trade has never been clear-cut. Now it is becoming increasingly blurred.

Digitization of all processes and the technical possibilities under the buzzwords "Industry 4.0" and "Internet of Things" make many things possible. A classic steel trader, for example, becomes an industrial platform operator that manages complete supply chains for its customers.

Many manufacturers see new opportunities through verticalization. They are discovering not only new routes to the customer, but also new opportunities in procurement and logistics.

The prerequisites are flexible and adaptable logistics and supply chain processes and structured data management. GTM can be used as a supplement to the standard SAP system for processing transactions in a wide variety of lines of business - and thus offers good prerequisites for all manufacturers who are opening up new sales channels and becoming retailers themselves.

Nobody has to fail at data exchange and order processing...

Old habits of thought

The advantages of verticalization for the manufacturer are manifold. One becomes more independent from the classic trade: Forward from the classic retailer, backward from the classic wholesaler.

Manufacturers who take on trader tasks themselves not only improve their margins. They also achieve greater data transparency across all process chains and can respond more flexibly - to special customer demands as well as to short-term fluctuations and bottlenecks on the raw material markets.

Do not overload employees

When manufacturers become retailers, they not only have to make bold strategic decisions about financing, inventory management and logistics. It is also important not to jeopardize the organization with the new tasks. After all, the motto is usually "Do one thing without leaving the other".

Employees usually have to take on new tasks without neglecting the previously traditional processes and activities. Verticalization is mostly an expansion of the business, not a replacement of the existing.

This makes it all the more important to have an IT infrastructure and a data processing approach that maps both purchasing and sales processes completely and simply and enables end-to-end transparency.

Trading Contract

With GTM, the standard SAP system offers all the options for transparently and congruently mapping further processes resulting from verticalization in addition to the classic processes of a manufacturer.

GTM traditionally represents various processes on the basis of a central document. The so-called trading contract is used to record all data resulting in the fulfillment of a customer order - from material purchasing to invoicing.

It integrates sales orders, purchase orders and all ancillary costs. This serves transparency and effectiveness because employees do not have to record work steps multiple times or in separate systems.

In addition, this method allows reliable controlling. Purchase and sales contracts can be associated with each other. Through the association on the batch level, a reservation of the articles for a sales contract takes place.

As a trader, you can see at a glance whether there is still sufficient trading stock or whether you need to reorder. By taking all costs into account and assigning them to one or more trading contracts, GTM shows in detail whether a transaction is being processed profitably.

Especially in the initial stages of verticalization, this direct profitability indicator, which is based on all cost and revenue types, is of great value: after all, managers could usually only fall back on little empirical knowledge.

After deciding to verticalize, a company has to relearn the complete pricing and margin policy - regardless of years of experience as a manufacturer.

DSAG announces need for expansion

With the GTM component, SAP offers all the possibilities for manufacturers who become retailers to map the flow of goods and services seamlessly and clearly, even under new conditions.

However, the GTM working group of the German-speaking SAP User Group e. V. (DSAG) also reports a need for expansion after consulting with customers who rely on GTM.

What is needed is a better integration of GTM into inventory management and stocktaking: For example, GTM cannot yet optimally map the consignment business, with which the manufacturer stores his goods at the retailer or customer before they are completely sold.

Here, an extension of the GTM component would save a lot of work and increase transparency. Inventory transfers and subcontracting items also need to be better integrated to enable lean and simple processing.

All new functions must, of course, take into account the association of contracts.

Verticalization

The good news: Compared to the strategic risks and the requirements for cultural and operational change that manufacturing companies take on when entering the new territory of "verticalization", the expansion of the SAP landscape is relatively easy to manage.

The GTM module is ideal for organizing the flow of goods. As an open system, it offers a range of expansion options. Before making the leap into verticalization, therefore, it is important to take stock of exactly which of the new trade processes can be mapped with the standard setting and for which add-ons need to be developed.