Variant configuration including pricing plus SAP

It was a simple use case in the context of a trade fair many years ago - but it caused visible astonishment among the professional community present:

The goal was to quickly and easily create or build a variant configuration with a direct transition to the quotation and order process.

For example, a ladder was configured live in the SAE configurator (with real-time CAD display) with automatic SAP-compliant pricing. The creation of a production order including material requirements planning, bill of material creation and explosion, plausibility and availability checks was automatically triggered by the system.

The subsequent automatic transfer of the order to the SAP ERP took place at the push of a button and led directly to the machine control. The production of the ladder in a ratio of 1:20 was automatically triggered and the small production line started running.

A complete process from the creation of models and configuration to order transfer and automated machine control in symbiosis with SAP ERP - and all this using the example of a simple product whose characteristics can nevertheless be manifold in terms of length, material used, muntin width, muntin spacing or the start of the first muntin. Industry 4.0 in 2003.

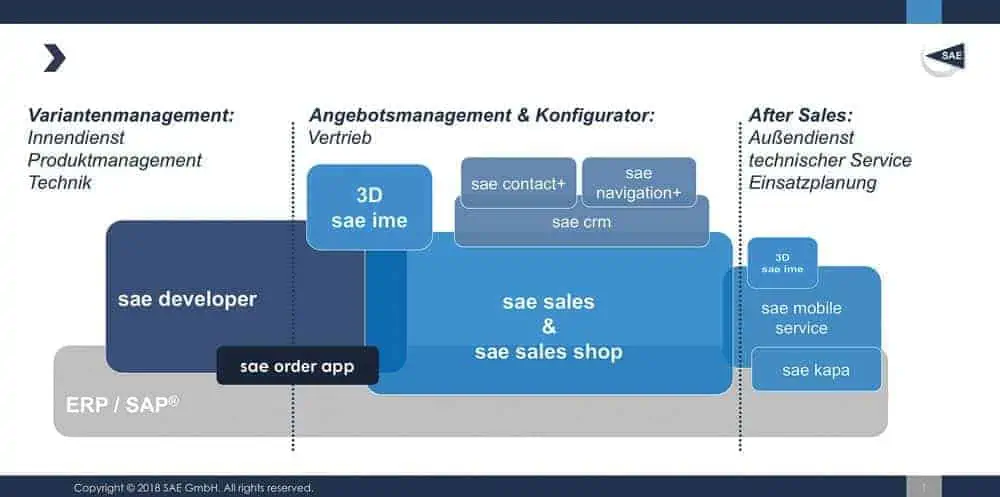

This tangible and demonstrative use case was implemented at the SAE booth with the SAE applications SAE Developer, the CPQ application SAE Sales incl. CAD and various SAE-own Abap solutions.

The fact that this presentation resulted in many concrete orders/customer relationships with partly well-known global companies was not planned, but an all the more pleasing result.

Today, companies of various sizes in more than 50 countries worldwide use SAE applications, including global key players with billions in sales.

Once founded as a management consultancy for logistics processes specializing in the topic of variant configuration and the efficient mapping of all internal company processes within the SAP standard, SAE GmbH operates as an owner-managed company with SAP certifications.

In doing so, the SAE team has broad SAP module expertise, CAD know-how across multiple vendors, and excellent software development experience in the latest technologies as well.

For more than 15 years SAE has been developing its own software applications such as the aforementioned Developer and Sales.

S/4 interfaces

The stand-alone sales management system from the CPQ environment features consistent interfaces to ERP/ECC 6.0 and S/4. Many years of experience with SAP and the web capability of the software solutions enable SAE to successfully serve a wide range of diverse customers.

Neutral database

A look at SAE Developer: It enables outstanding sales data management based on SAP ERP or SD data, including the complete SAP LO VC objects with object dependencies.

The SAE solution generates native data from the existing ERP data, i.e.: a completely neutral database. All data objects that are necessary for a quotation or order creation are generated, prepared or transported via the developer.

Complex price data, perfectly formatted texts and the most sophisticated document customizing allow individual print creation. For example, SAP configuration data can be enriched, revised, verified and prepared for further sales processing in a comprehensive manner.

Also, all desired sales data can be built or modeled autonomously in SAE Developer. The solution also provides optimal support for the essential core value creation processes of efficient variant management in line with requirements:

From the use of a distinctive structuring platform for variants, the visualization and simulation of object dependencies and configurations with country- and sales channel-specific versions, the enrichment of technical configurators to sales-optimized configurators, the use of an inside sales workflow for quotation and order processing, the use of a central database and communication platform for subsidiaries and sales companies to the use of a central control platform for the relevant CAD models.

Highlights include: cross-instantiation between subordinate objects, parts list processing over several levels, editing and checking of object dependencies with automatic code suggestions. SAE Developer is used by large and medium-sized companies in mechanical and plant engineering.

Due to the modular structure and the individualizable (customizing) functions, the company-specific requirements and goals are realized in a demand-oriented and highly efficient manner. SAE Developer thus provides functions and applications that go far beyond the standard ERP solution.

For customers, the SAE solution is used in the sense of a functionally extended "middleware" for preparing the SAP configuration, the sales options and the sales prices (master list prices and sales prices of the subsidiaries) for the CPQ process - also as a web solution.

Here, for example, for the data transfer from SAP and the PDB, the structure of country price lists, the country product characteristics and the marketing-oriented addition of the sales configurations.

The transfer of relevant CAD data for sales configurations or other applications is realized via SAE MX Developer.

Quotation and sales processes under control

The focus is on the SAE Sales solution, which is an offline as well as web sales application that effectively supports sales teams with sales- and practice-oriented interfaces and functions in all phases of the quotation and sales process.

The flexibly implementable offer configuration, the offer pricing including the storage of offer documents, a sales-oriented CRM project folder management, the extensive text and document management, the Outlook integration, the 3D model creation up to an automated data transfer to SAP systems represent only a small part of the functions. Whereby SAE Sales can be used both as an online and offline system.

A significant advantage is that technically demanding products and their variety of characteristics are clearly presented with SAE Sales in a customer-oriented manner.

As mentioned, the SAE solution has its own CRM module with an offer-specific workflow. It supports the sales process and thus the field sales force in an ideal way.

The Outlook integration as well as the up- and download functions at the push of a button to an SAP system are SAE standard functionality. The connection of already existing CRM systems is also possible (such as Salesforce or C4C).

Still profitable: SAE Sales enables a highly efficient and error-free workflow in the quotation and sales process. Throughput times are reduced, processing is massively facilitated for everyone involved in the workflow, and sales costs are lowered at the same time.

Quotations created offline or on the web from the SAE Sales application are transferred one-to-one to SAP within the workflow process via the SAE-SAP interface.

Interactive Motion Engine

With the Interactive Motion Engine, SAE sees itself as a pioneer in the field of global quotation and configuration software and sets new standards. After all, the SAE Interactive Motion Engine enables variant products up to complex plant systems to be individually displayed in 3D on the basis of virtual reality technologies and to be fully dynamically pronounced and interactively "moved" (by generating a computer-generated reality).

The result can be a high quality quote with custom images and custom pricing within SAE Sales. It can also be used in other native applications.

An essential component of a future-proof solution for the visualization of configuration on different platforms is a uniform database in the form of a digital core. The SAE Interactive Motion Engine is used to generate this database and such a data format.

The highlight here is that the configurations from the leading ERP system (SAP ERP or SAP S/4 Hana) are merged with the existing CAD data (which is converted at the push of a button) to create added value.