TMS Monitoring and Reporting

In view of the technological change that is already in full swing with regard to S/4, high demands on supply chain stability and sustainability, resource bottlenecks and increasingly short-term deliveries, a fundamental rethink is necessary in transportation management. In order to adequately meet the challenges of the future, the importance of real-time information and integrative aspects in transportation management has increased enormously. What does a TMS have to do today to keep up with the world? One answer is the shift from transport management to active transport control.

With regard to the SAP community, the discontinuation of SAP ERP/ECC 6.0 and LE-TRA (transport solution, TRA, within the logistics component Logistics Execution, LE) means that established options for transport mapping are no longer available. Although a successor is available in the form of S/4 Transportation Management, this forces companies to re-implement it, since a migration from LE-TRA to S/4 TM is not available. Taking into account a new implementation of the successor solution, process changes based on external factors and business requirements, the topic is currently being re-evaluated by many companies.

Supply Chain Resilience

One buzzword that has been making the rounds with increasing frequency over the past two years is supply chain resilience. Ultimately, this is nothing new. Back in 2009, the term was defined by Ponomarov and Holcomp as "the adaptive ability of a supply chain to prepare for unforeseen events and respond to disruptions." In order to actively intervene in the processes and, in the best case, to act at an early stage thanks to new technologies - i.e. before a disruption even occurs - a holistic view of transport and plant logistics is required.

It is time to break up historical realities and break new ground in order to integratively merge the management and execution of transports and to map an end-2-end process in terms of systems technology. The specialist departments in companies are currently under particular pressure to transform. In addition to the shortage of truck drivers and rising transportation costs, the issue of sustainability, combined with the new supply chain law, is forcing companies to rethink their supply chains and find more sustainable ways to map processes.

Furthermore, there has been a trend in procurement logistics for some time now for purchasing and logistics to move closer together in order to digitalize the inbound process holistically and increase supply chain resilience. As a result, the topic of risk management is increasingly coming into focus. This involves concepts that make it possible to react to possible impairments at an early stage: for example, to flexibly change sources of supply, carriers and routes and to clock the warehouse and production accordingly so that the end customer experiences a high level of service. This inevitably leads to the creation of supply networks that permanently involve partners in the core processes.

The example of the inbound process quickly makes the importance of transport control clear: The point is that transport planning must take place in an integrated manner in the system network on the basis of feedback from the suppliers by making packaging information or the possible pickup date available to it. All relevant information - whether via web, e-mail or electronic connection - is required at the leading digital document so that information can be successively updated along the process to ultimately actively control the transport and no longer just manage it.

In outbound, the focus is increasingly on saving costs, minimizing the number of transports, and making the best possible use of the purchased transport. Here, too, the issue of sustainability is of high importance. Whereas in the past the focus was often on area freight forwarders and regular transports, there is now a trend for transport logistics as a discipline in companies to become more and more centralized, especially on the premise of combining inbound and outbound transports. As a result, transports are to be planned and executed across different transport modes throughout the company.

However, the trend also means that subsequent processes must not only be better planned, but also executed. Time slot management that takes into account the capacities of the warehouse and dynamically calculates the loading processes in terms of time, followed by integrated inflow control based on real-time data, is elementary in order to process the trucks as quickly as possible and transport the individual deliveries together. This also includes a fully comprehensive yard management system that proactively detects the inflow, reports bottlenecks in the yard in good time, and uniformly controls the activities along the loading process.

On the IT side, this leads to a realignment of the IT architecture used to date. In particular, the aim is to break down silo systems, avoid media discontinuities and create a combinatorics of process worlds.

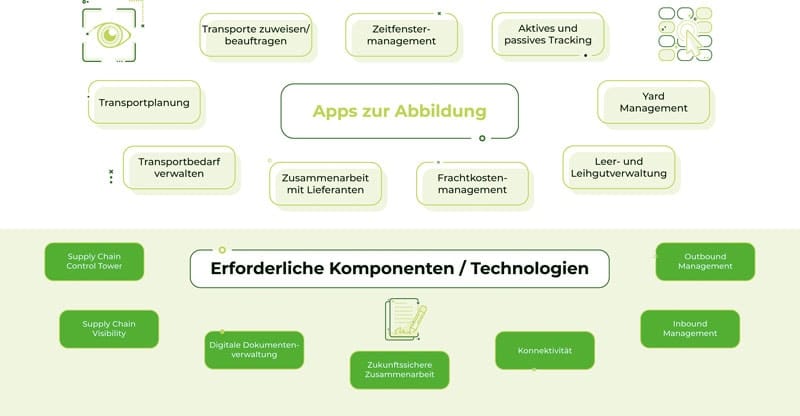

A solution is often used for inbound collaboration with suppliers and the associated notification. However, other solutions are then used for delivery control, yard management or track-and-trace. In outbound, different applications are used in some cases for the same processes, as the work areas can make their own IT decisions. It may also be common practice for sub-processes to be mapped via e-mail, spreadsheet processing, fax and telephone. This situation makes it more difficult to operate and contradicts the concept of a resilient supply chain. Active transport control urgently requires a harmonization of both worlds in order to allow interventions that take upstream and downstream processes into account.

Comprehensive platform solutions

Particularly in the SAP environment, the motto "Keep the Core Clean" applies under S/4 and, associated with this, the streamlining of IT systems used along the process chains - especially in a global context. The aim here is to reduce the heterogeneity of solutions and providers to a minimum in order to achieve an integrative architecture. This helps to ensure smooth operation, standardize different technologies and, in the best case, enable outsourcing in the context of AMS (Application Management Service). It should be noted here that in-house developments should be reduced as far as possible and processes with a high division of labor should be outsourced from the core.

Based on AI, blockchain and the use of cloud applications, supply chain resilience concepts and transportation mapping can be implemented. Process-as-a-Service platforms such as those from Leogistics are already meeting the increasingly urgent challenges of business and IT. Because with a highly integrative cloud platform, the relevant information is available to all parties involved at all times and processes can be intervened in predictively and ad hoc at any time in order to actively control them.

The combination of an SAP system and the Leogistics platform enables a high degree of automation in the digitization of processes. The result is not only an IT architecture with a "clean core", but also transport logistics based on S/4 Hana that already takes into account the challenges of the future.