The digital factory of the future

Leading enclosure and systems supplier Rittal, a Friedhelm Loh Group company, is investing in its German sites in Haiger, in Hof and in Rittershausen.

By 2018, the world's most modern compact housing plant with highly automated digitalized production will be built at the Haiger site, in line with the principles of Industry 4.0.

To this end, the three-stage production of compact housings, consisting of sheet metal working, painting and assembly, is networked throughout.

9,000 compact housings are to leave the state-of-the-art plant in Haiger every day. Industry 4.0 structures form the basis for highly efficient production, logistics and communication processes.

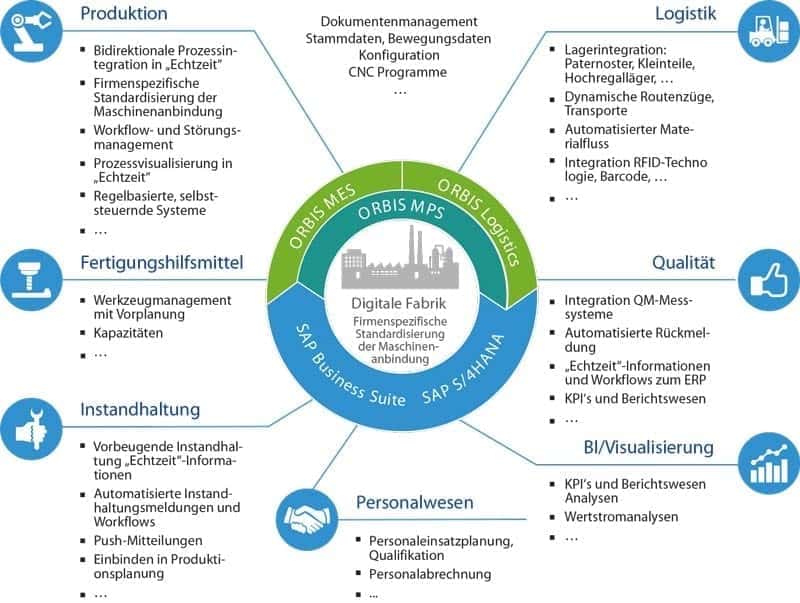

In this factory of the future, Orbis, as an IT specialist for Industry 4.0 solutions, has the role of digitization partner.

Manufacturing down to batch size 1

"In the new plant, we will digitally network all work steps - from the customer's order to production and logistics."

"In the new plant, we will digitally network all work steps - from the customer's order to production and logistics."

explains Carsten Röttchen, Managing Director Production.

"In this way, we will be able to manufacture the approximately 9,000 small housings per day highly efficiently in the future and, if necessary, up to 'batch size 1'."

Digital networking and the associated highly automated production are implemented by Rittal with Orbis Manufacturing Execution System (MES) and SAP ERP.

Orbis MES networks the store floor processes bidirectionally with the SAP Business Suite. The digital factory is planned entirely in the SAP system and controlled with Orbis MES.

The SAP integration of Orbis MES has been certified by SAP with the "Powered by the SAP NetWeaver Technology Platform" seal of approval.Orbis MES allows full integration of MES processes into the processes of production planning and control (SAP PP), maintenance (SAP EAM), quality management (SAP QM), logistics (SAP LES) and human resources management (HCM).

Only this high level of process integration makes it possible to automate the process flows in the smart factory. In the SAP system, a virtual image of the real events in the factory is thus created in "real time".

Networking SAP ERP and production

A central component of Orbis MES is machine data acquisition (MDC). This integrates machines directly into SAP processes. The data obtained is always prepared in user-friendly dashboards.

The result is a complete visualization of the machine and system states of production and assembly as the basis for transparent and efficient manufacturing.

Orbis MES can be used to control processes with machines, terminals, sensors, scales, controllers, I/O modules through to signal lights, RFID scanners, Bluetooth components or even mobile devices, etc.

Another component of Orbis MES is store floor data collection (SFDC). This actively integrates people on the store floor level into the process flows of the paperless factory.

Comprehensive and reliable information on order throughput is available in "real time". The people involved in the production process are integrated via a proactive push principle.

Completely paperless manufacturing

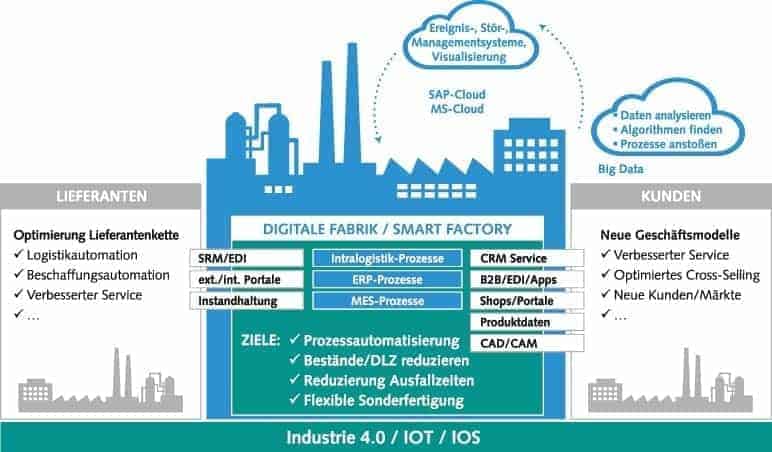

The goals of the digital factory in the context of Industry 4.0 are end-to-end automation and monitoring of processes across the entire value chain. The aim is to map batch-oriented production of series products through to customized production in quantities of one.

The aim is to achieve paperless production in which the components of the technical infrastructure (machines, systems, sensors, software, etc.) are networked or integrated bidirectionally.

Inventories and throughput times are reduced by fully automated production, logistics and communication processes. Digital fault management, which triggers event-driven automated processes, reduces downtimes to a minimum.

"For us, Industry 4.0 means flexibilization and automation, and as process-safe as possible."

"For us, Industry 4.0 means flexibilization and automation, and as process-safe as possible."

explains Moritz Heide, Group Manager Production IT Design.

Orbis uses its own solutions to implement the digital factory, using the existing SAP ERP system as a control system to integrate and visualize processes.

All Orbis solutions for Industry 4.0 are therefore fully integrated into the SAP Business Suite. Digitization projects can thus be easily implemented in an existing SAP environment - step by step or completely.

Orbis has developed the Orbis Multi-Process Suite (Orbis MPS) to automate processes in the digital factory end-to-end.

This digitization suite integrates machines and devices bidirectionally into SAP processes and enables end-to-end and transparent processes.

Process interruptions, for example in the form of "manual" data entry, are replaced by a rapid automated exchange of information.

This transforms what was previously a manual and step-by-step process handling into an end-to-end integrated process chain. Orbis MPS can be used in all processes of a company and is the basic technology as well as an integral component of the Orbis MES and Orbis Logistics solutions.

Through the interaction of industrial processes with fully automated logistics, quality and maintenance processes in "real time", the store floor is mirrored 1:1 in SAP.

One of Rittal's key objectives with regard to networking the store floor with SAP ERP using Orbis MES is a standardized connection of the technical infrastructure. This means, for example, that machines and systems can be networked or integrated within a very short time and with manageable effort.

This also significantly reduces the maintenance effort. Norbert Ruppik, Project Manager IT, summarizes:

"For the first time, we're creating complete vertical integration with IT here, from the ERP system to the PLC on the machine."

Control loops for event-oriented production

Orbis MES allows Rittal to automate manufacturing processes based on control loops. For example, replenishment control for tools and production material is handled fully automatically via autonomous control loops.

For this purpose, the real production structure is virtually mapped in Orbis MES. The main advantage is that replenishment control runs according to demand and "event-oriented".

In other words, if the material supply runs low, replenishment is automatically initiated by the system - completely self-organized and just in time.

These control loops can also be used to implement exception and fault management, in which processes are triggered automatically depending on events.

For example, corresponding faults can be forwarded to the responsible employee according to the push principle, so that manual intervention in the production process is only necessary in the event of a fault.

If limit values are exceeded, an alarm is automatically triggered, which initiates the ordering of spare parts and a maintenance or quality management order and informs the employee about the pending repair.

These highly automated processes enable precise production planning.

"Planning is no longer done in production days. In the new plant, planning is done to the second".

comments Moritz Heide.

Visualization in "real time" creates transparency

Orbis technology is also used for the visualization of machine data. The employee at the machine benefits from the real-time-based and simple information display and, for example, recognizes malfunctions immediately.

Production and process data, for example from manufacturing, are clearly visualized on a web-based, intuitive interface. They can be accessed by the end user in accordance with their role and authorization at any time and from anywhere on any end device.

By linking the store floor level with the management level, Orbis MES clearly delivers the right information to the right person at the right time - the entire factory becomes transparent.

Fully automated one-piece flow as a pilot project

As part of a pilot project, Orbis has already implemented a one-piece flow process at Rittal's Herborn plant that is fully integrated into SAP Business Suite.

In this fully automated process, the entry of a customer order including the desired special modifications is graphically supported in direct communication with software products from Eplan and Cideon as well as the data transfer to SAP.

In this fully automated process, the entry of a customer order including the desired special modifications is graphically supported in direct communication with software products from Eplan and Cideon as well as the data transfer to SAP.

The drawing and NC program are automatically generated and seamlessly transferred to Orbis MES. Orbis MES then uses this data to control a laser robot, which then performs the corresponding housing machining.

This highly efficient networking and automation has made it possible to individualize products down to batch size 1, one of the key objectives of the digital factory in the sense of Industry 4.0.