Security for the system change

In addition to company-wide migration to a new ERP system, there are many occasions for larger data migration projects: company acquisitions, integration of operating units, suppliers or foreign subsidiaries are just as much a part of this as the integration of PLM or e-commerce systems. The challenges arise in three dimensions: the sheer volume of data, the unbelievably large number of details such as field lengths, data formats, languages, units or number ranges, some of which first have to be converted at great expense during a transfer and then assigned correctly, and finally new requirements that are to be met with old data stocks.

Software and best practices developed

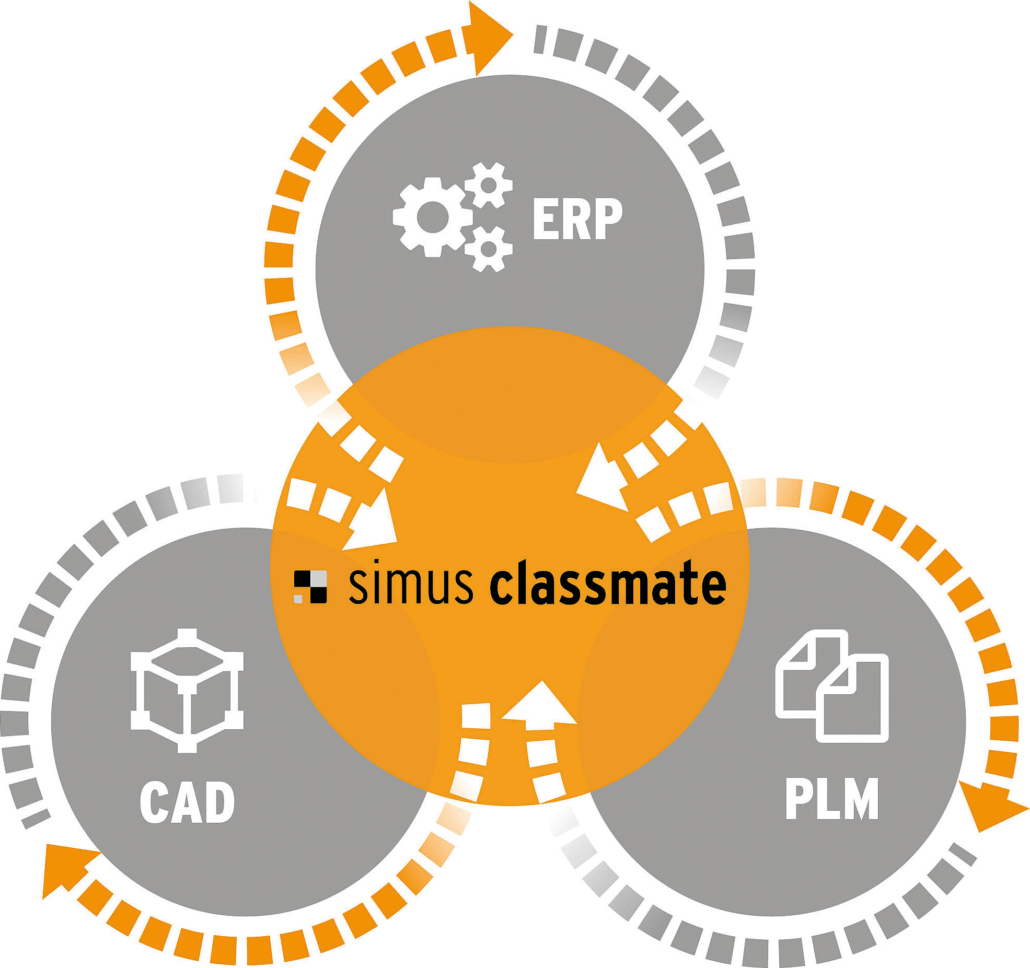

simus systems addresses these challenges with the simus classmate software suite, which includes the classmate DATA program. In a first project step, a customer's legacy data is read in here, analyzed, structured and cleaned. CSV or TXT files with unstructured data from ERP or PDM systems are systematically condensed, enriched and structured via integrated, customizable rule sets.

Together with the customer and a possibly involved system house, mapping tables are developed for each data group, which define the data distribution to the respective target fields in the new system. Simus systems then implements these rules in simus classmate and begins initial tests.

Finally, the mapping information is fully calculated and written to a database for each object type. This creates a flexible, independent database that can be used for cleaning and modifying material masters, documents, equipment and routings as well as for meeting new requirements. Depending on the object type and target SAP system, this data is prepared accordingly.

By means of the classmate SAP interfaces, the selective transfer of data for creation or modification in the new SAP system is then successful. Finally, error logs are evaluated for quality control, quantity checks are performed and the process is documented.

Introduction or adaptation of a classification

The second step is to ensure that the data remains well-ordered and findable in the long term. For this purpose, it makes sense to adapt, expand or introduce a classification, which is usually developed in workshops with the customer.

Classmate DATA supports standards such as eCl@ss as well as company-specific classification systems. The main advantage from using the software is that the classification is not only theoretically derived, but is actually built up in an evaluated way based on the existing data and content. An industry-specific best practice class system, developed by simus systems as the essence of numerous projects, can be used as a basis.

Characteristics and classes can be defined via the simus classmate interface not only during the creation of new objects, but also during necessary optimizations and adjustments. The objects can be automatically classified and evaluated as well as checked for conformity with SAP. Manual interventions are also possible. The mentioned classmate SAP modules also open read and write access to structure data such as classes, characteristics and object dependencies.

Application example Piller compressors

How such a project works in practice can be seen at Piller Blowers & Compressors GmbH. Simus systems advised the internationally positioned manufacturer of blowers on setting up a classification system and preparing the master data for a migration of the ERP system to SAP S/4HANA.

In the process, the entire material master was fundamentally revised, massively reduced and the data quality significantly increased as a result. simus classmate was introduced for classification and master data maintenance: User-friendly tools synchronize the data directly with the ERP system since then.

As a globally active family business, Piller develops and manufactures high-performance blowers for the process industry. When the technology leader decided in 2016 to replace its existing ERP system with SAP S/4HANA, the master data was examined for migration capability. "Around 360,000 material masters were searched for and found using short texts," reports CIO Thomas Henzler. "Since these texts are limited to a small number of characters in SAP S/4HANA, a complete reorientation was necessary."

In the first quarter of 2017, a project began with two goals: building a specific classification for better retrieval and improving data quality for migration to S4HANA. simus systems was selected as the service provider: "On the one hand, we were impressed by the high level of technological understanding and the wealth of project experience of simus' mechanical engineers.", explains Thomas Henzler. "On the other hand, with simus classmate they have brought along optimal tools for direct use in the SAP environment."

A customer-specific classification with subject characteristics was developed with all departments. The data master was tested and optimized until an optimal status was reached. In the process, the number of material master records was reduced by almost half.

With the support of simus systems, the data migration was completed in time for the go-live on 2. 3. 2020. "Simus knows the SAP data structures in detail and was able to support us as a new user in the best possible way"., Henzler is pleased. "Among other things, with this experience we have managed the data migration." An automated material master creation process now ensures that, as far as possible, only complete and error-free master records enter the new ERP system. During the project time, the decision was also made to introduce some tools from simus classmate in the company: "The solutions like classmate FINDER work super fast, transparent and user friendly" says the CIO. "After looking at the same processes in the ERP system, our decision was clear." All users of the new ERP system now benefit from the data quality they have gained. "The results of S/4HANA's graphical analysis tools always correspond to the underlying data quality", reports Thomas Henzler. "An order trend by merchandise category therefore only provides real insights if the merchandise categories are properly maintained."

Broad customer base in the industry

Just like at Piller, numerous projects run with simus systems, which can be successfully completed due to intensive knowledge of the processes in the manufacturing industries and the SAP systems. With the experience of more than 18 years and a competent staff, new challenges are gladly accepted.