Orsoft: Modeling the Digital Factory

Furthermore, new ideas are already maturing in the labs of software developers. Orsoft, one of the leading development and consulting companies in the field of planning software, provides an insight into this development. The consideration of planning as a holistic tool for the control of business processes is at the top of the agenda. Autonomous processes are accordingly included on the entire shop-floor level and modeled based on digital twins.

Before delving deeper into the subject, it is important to clarify and differentiate between a number of terms. When classifying the term artificial intelligence (AI), Orsoft uses the definition of the market research specialist for supply chain management Gartner. AI applies advanced analytics and logic-based techniques, including machine learning, to interpret events, support and automate decisions, and take action.

As a subset of AI, machine learning (ML) aims to train an algorithm through repetitive training so that it can perform tasks autonomously. Unlike conventional algorithms, the recognition of (data) structures is not predetermined by an implicit model structure but is left to the “machine” autonomously.

Autonomization of planning processes

With the patterns recognized from the ML, the prognosis quality of time series-based processes attains a completely new quality. The highest goal of ML to date is autonomy. In differentiation to automation, Fraunhofer IESE describes the terms as follows: if it is known how a system behaves in a certain situation, it is automation. If this is unknown, we speak of autonomization.

Enhancing existing Enterprise Resource Planning (ERP) systems with advanced planning systems (APS) is the goal here. Since ERP is not explicitly designed for planning tasks—for example, only rudimentary inventory controls or simple planning processes such as MRP runs can be mapped—additional advanced planning systems are often used to represent and optimize transactional business processes. However, these no longer meet the expectations of today’s planning reality.

The systems, which are often not very agile, neither represent entire supply chains nor the possibility of ad-hoc plan adjustments close to the batch size of one. With its software tools for strategic, tactical, and operational planning, Orsoft has always pursued the integrative end-to-end approach to planning—that is, to model all planning instances holistically, intelligently linking them with each other, and creating a wide range of simulation and forecasting options. These characteristics are the basic prerequisite for the application of (partially) autonomous planning instances, the third major disruption in supply chain management after ERP and advanced planning systems.

Digital twins

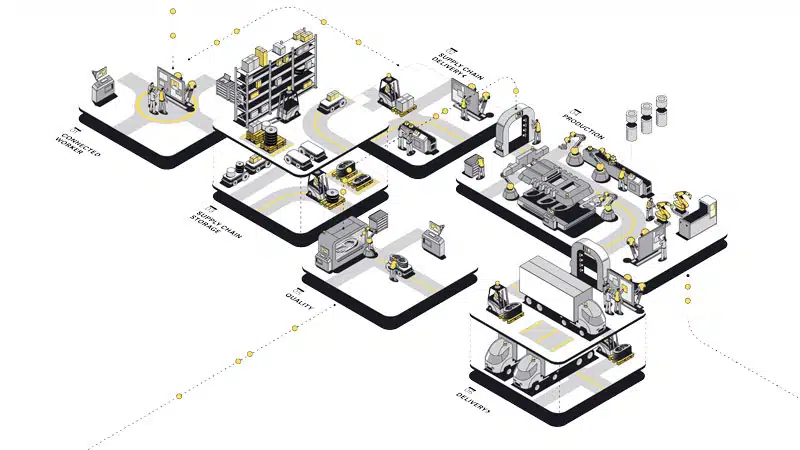

Autonomous planning instances are to be modeled using digital twins. But what actually is a digital twin? Analogous to genetics—where identical twins share identical DNA—the digital twin shares specific functional properties with its real counterpart. Transferred to industrial reality, this can include, for example, the shop-floor and its digital copy in production or a digital supply chain twin in planning.

The digital supply chain twin is the basis for the autonomization of planning. With it, processes become more networked, efficient, agile, faster, and more transparent. The more complex the value chains—a plant with a sales unit or a comprehensive network of production, purchasing, and sales processes make a big difference—the more necessary the real-time synchronization of data between the planning instances and the central ERP becomes.

A uniform data layer with maximum detail, data integrity, and response time can be provided through the modularly expandable and interface-open PaaS platform Edge.One. This allows numerous processes from the shop-floor and the top-floor to be mapped and integrated into the central platform approach of a digital factory.

Advanced Analytics

Advanced analytics is no longer limited to the past-related descriptive analysis of data (the question of “What happened?”), but focuses on predictive (“What will happen?”) and prescriptive (“How can I achieve this outcome?”) analysis.

With advanced analytics, scenarios can be mapped and executed automatically on the basis of pre-defined goals or goal hierarchies, such as maximum customer service, customer segmentation, a margin-optimized production program, and more. Prioritization rules help to resolve conflict situations in the best possible way and to automate them through machine learning. Depending on the complexity of the plan optimization, the (human) employees can be partially or completely relieved of decision-making authority.

Based on ML analysis of time series, reliable forecast values are provided for demand planning. In this way, fluctuations in the supply chain can be reduced and subsequent processes improved. The conclusions for inventory management are equally evident: the reduction of necessary safety stock to cover demand fluctuations is another important goal. With the help of AI, inventory management can be switched to dynamic safety stock. Reactive scheduling is another buzzword in AI-supported planning. Here, the planning run is described as an agile process that is open until the last minute. The goal is to be able to react to changing conditions – ad-hoc orders from an important customer, reordering, delivery bottlenecks, employee/plant breakdowns, or similar. Continuous learning from decisions made in the past continuously “feeds” the AI with data. An always up-to-date planning engine in the background, fed by the live system, helps to marginally and continuously adjust the initial plan.

Machine learning methods also provide interesting features in conflict management. Based on earlier decisions and the analysis of the results, suggestions for the solution are provided and autonomized, if desired. By comparing planned production and real feedback from the shop-floor, the quality of the plan can be evaluated and fed back into the modeling of the algorithm—also with regard to the implementation of maintenance forecasts. Alarm functions are also (partially) automated and self-learning through AI-supported decision processes.

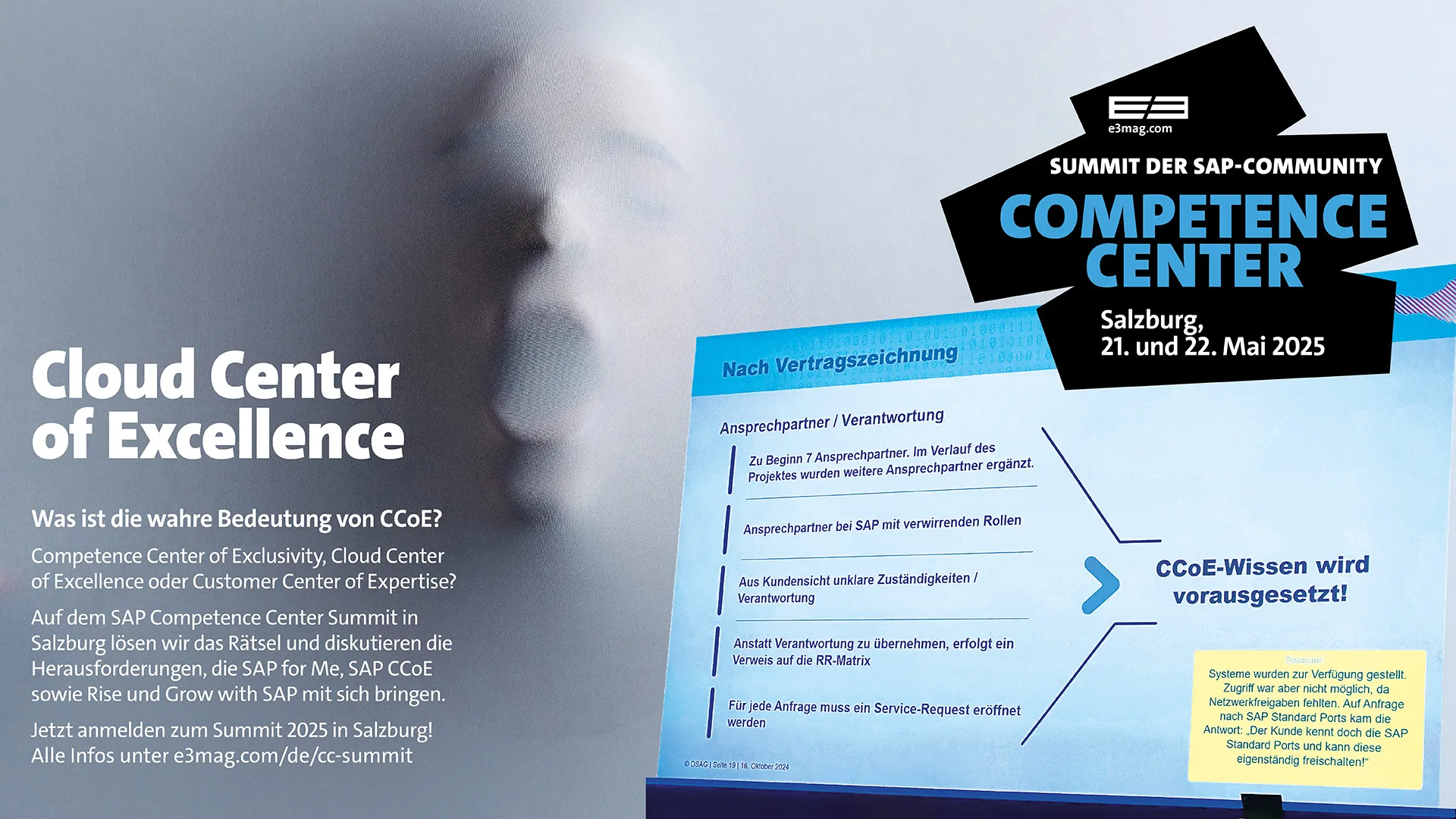

SAP systems

Automation of advanced planning and scheduling in SAP systems is an Orsoft use case. The customer’s requirement was clearly defined: Touchless autonomization of operational planning with the goal of implementing a system that works autonomously in the normal case—in the so-called happy flow—and that can automatically involve planners when certain events occur. The following additional constraints were agreed upon: automatic (iterative) interaction with SAP, strong configurability of the data model, automatic reaction to certain, freely configurable events, and the execution of functions on a separate application core, which allows the software to be operated even without logged-in users.

In order to do justice to an autonomization of operational planning, goals of the planning run, which are represented as given prioritization rules – also graded as sequence of priorities -, must be defined. Like the boundary conditions, these can be set in detail. All SAP fields – including those of referenced objects, e.g., the customers for the sales order of a planned order – can be configured both manually and automatically and ranked by maintaining limit and exact premise values. In the specific case, the consideration of material availability/procurement times as well as personnel availability and qualification were specified by the customer as explicit boundary conditions.

Thanks to the bidirectional real-time synchronization with master and transaction data in SAP, the plans created are always aligned in terms of capacity at the plant and material level. Orsoft applies a complex MRCP (Material Resource Capacity Planning) run with finite (limited) resources without overloads, which is not available in SAP. In the specific application, material provisions from customers are also integrated into the planning run. A CTP (Capable to Promise) instant check implemented by Orsoft and interacting with SAP acts as a trigger for planning autonomization. Only if there are target conflicts or missing resources on material and capacity level, automated alarms are displayed and sent as an e-mail alert.