Mechanical engineering pioneer in batch size 1

The pioneer in the field of batch size 1 is mechanical and plant engineering. Two thirds of the companies in this segment are already striving for the new level of individualization.

These are the results of the German Industry 4.0 Index, which has already been surveyed for the third time.

The fact that machinery and plant engineering in particular is making headway is no surprise.

After all, this industry is traditionally characterized by comparatively low unit volumes and customization according to customer requirements. Industry 4.0 takes this principle to a whole new level.

A current example such as the machine tool manufacturer Trumpf shows that batch size 1 is already a reality through digital transformation: from the customer's configuration in the electronic front end to the delivery of a finished individual punching tool.

Other sectors, such as the electrical industry, are also catching up. As successful as individual companies may already be with batch size 1, many companies still have a tough road ahead of them.

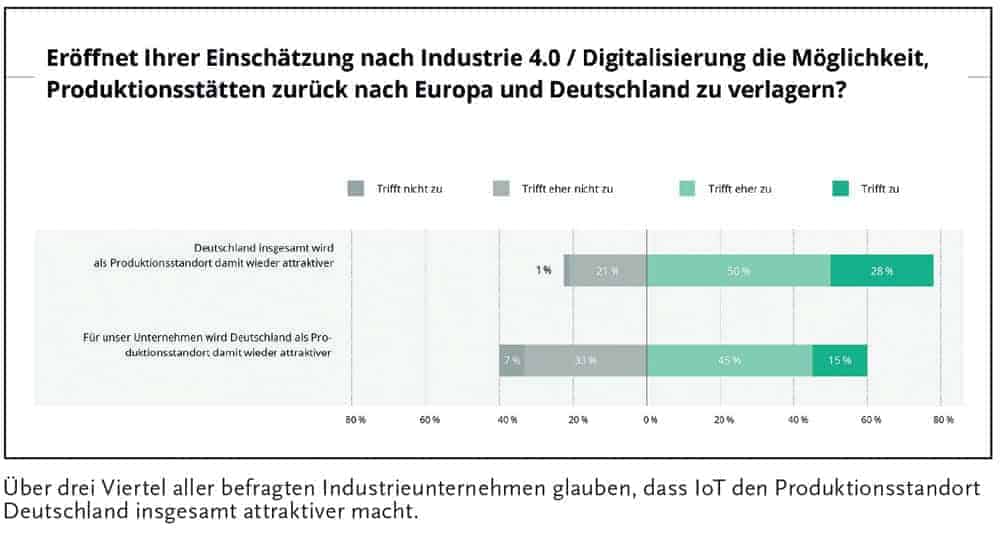

Industry 4.0 concepts only develop their full potential when the entire value chain is included. A side effect of the digital transformation: high-wage locations could become more attractive again.

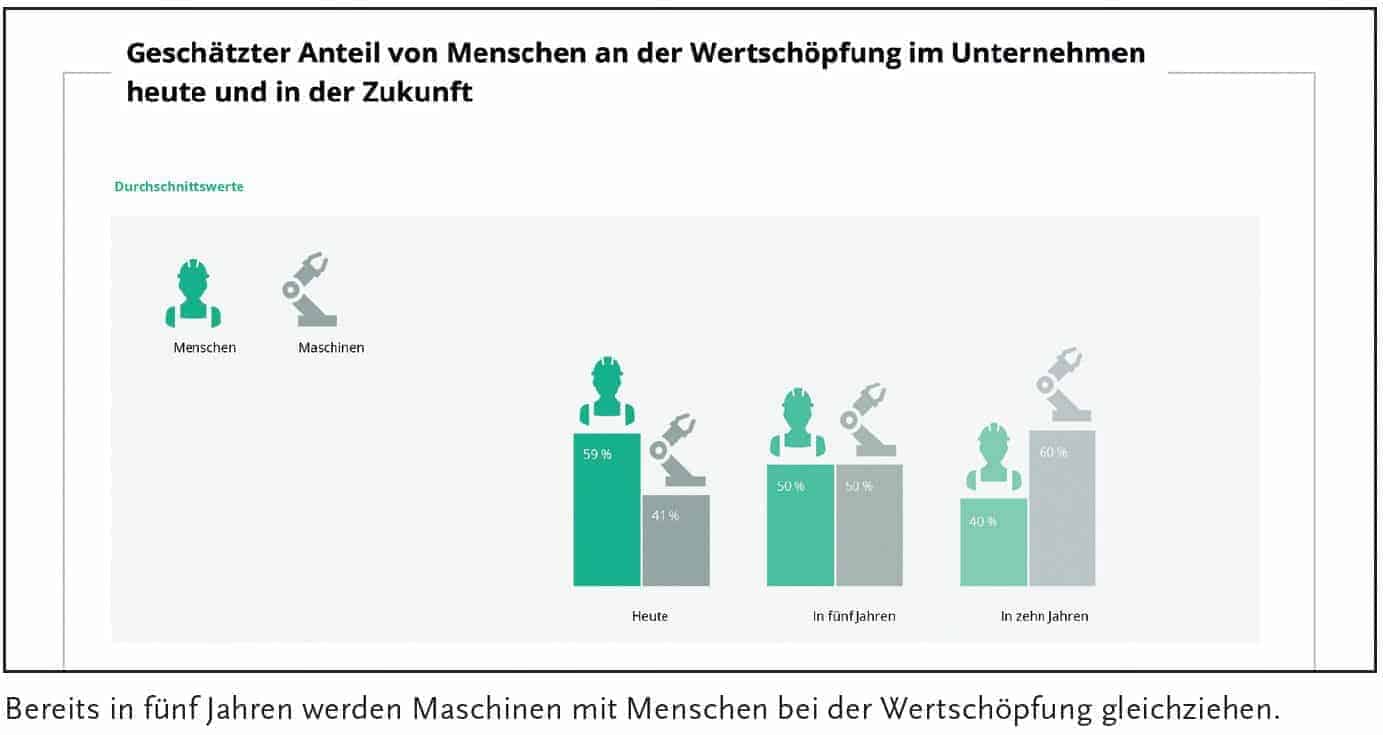

According to the study participants, in ten years' time humans will only account for 40 percent of value creation, meaning that machines will soon account for the lion's share.

Due to the decreasing share of labor costs in total costs, companies could rediscover Germany as a production location - also against the background of local, agile supply chains.

This is the belief of 78 percent of those surveyed for the German Industry 4.0 Index. Despite further automation and increasingly autonomous machines, industry will not be able to function without people in the future. However, job profiles are changing.