Interactive Virtual Reality in the CPQ process

The growth in sales and market share of machinery and plant manufacturers is largely due to the fact that products or entire product system solutions can be offered in an increasingly wide range of variants, and this worldwide.

This ability is becoming the decisive success factor for the future of companies. As digitization progresses, the companies that continue to be successful will be those that embrace the disruptive nature of this development and open themselves up to meaningful new opportunities and techniques.

This development will not only continue, but will also be significantly intensified by the use of various digitization options. Industry 4.0 offensives, including IoT, networking of digital products, a significantly higher degree of automation, even faster development cycles, and the use of enterprise solutions such as S/4 as a "digital core" are in demand among manufacturing companies - in order to be able to manufacture or produce products with a wide range of variants practically at the push of a button or in the shortest possible time.

At the same time, it is essential to expand or transform the sale of complex and variant-rich products in the direction of 4.0.

Homo digitalis and customer journey

The hallmark of the current sales environment is extreme global competition, which provides the buyer as "homo digitalis" with a large number of suppliers offering customized product ranges.

A high degree of identification of the prospective customer with the offered product and the successful presentation of the USPs (unique selling propositions and competitive advantages) during the sales process are decisive for a successful offer process.

This can be ensured with virtual reality scenarios. Additionally important is speed, that is, the time in which an appealing and correct offer can be presented, even for complex products and plant systems.

For the manufacturer, in addition to successful order generation, the certainty of an error-free configuration with correct pricing is crucial. Another essential factor for a lucrative order is the quotation generation costs.

This means that internal coordination rounds for technical feasibility checks or the redesign of layout plans must be avoided.

The sales department itself must be able to carry out these necessary checks and adjustments within the framework of the regulations. In order to be able to offer firstly quickly and secondly without incurring additional internal costs. In addition, a new customer behavior will develop in the decision-making process.

In the future, prospective customers will access digital information offerings on their own initiative - especially those that make use of virtual reality technologies. A large part of the selection process, the so-called customer journey, has already been completed with the request for quotation from the provider.

The customer then expects fast, competent and precisely fitting offers. These requirements are only met in a symbiotic use of ERP and CAD data within the CPQ process.

Sales and Service 4.0

Identifying new customer needs and market developments quickly and responding to them better than the competition is one of the competitive factors in the age of digitalization.

In concrete terms, the next level in the quotation process means that even greater digitization is taking place externally. With the use of so-called digital twins, product data from the design and ERP environment is transferred to new digital areas of application.

Product preparation for virtual reality makes it possible, for example, to bring a product's USPs to life. Further added value is created in service, for example, as virtual reality instructions can be generated for each customer-specific system.

At the same time, data preparation takes place from the outside in, for example through automated and comprehensive back import of customer-specific order data into CAD systems and, of course, into ERP solutions.

CPQ bridging

Configure Price Quote software solutions have long been effective in supporting sales teams in the processes involved in preparing quotations. The focus is always on complex products with a large number of variants and characteristics.

CPQ systems significantly simplify and accelerate existing configuration processes. As a rule, they include a product configurator and can be linked to or extended by CRM (Customer Relationship Management) systems.

At the same time, they create a connection to an ERP system, namely ERP/ECC 6.0 or S/4 (LO-VC), to ensure the exchange of relationship data, for example.

But also, for example, to generate production orders (for example, with material requirements or bills of materials) from a created quotation or to trigger the manufacture of a product (following plausibility checks or simulations).

Agility and Virtual Reality

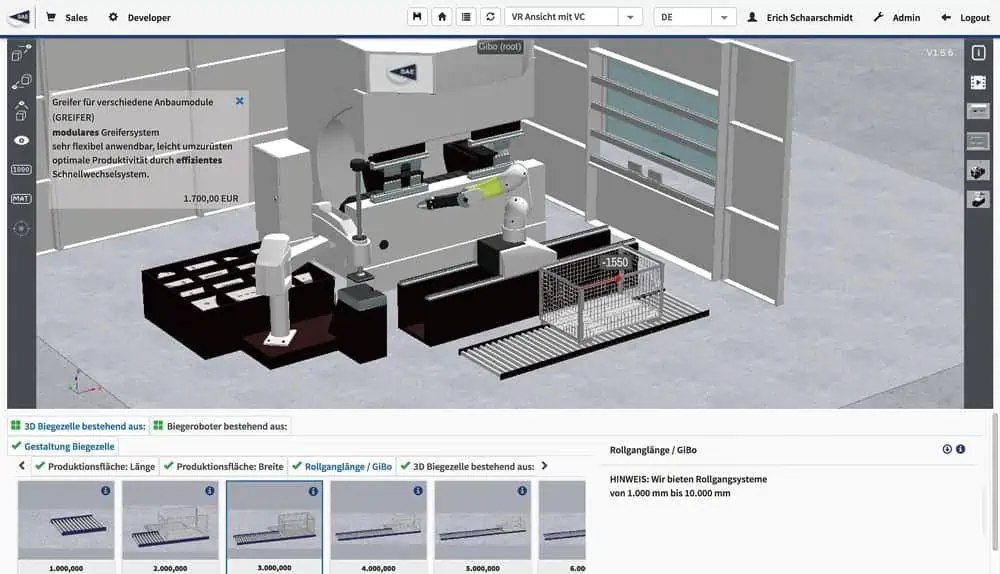

SAE has realized the principles of a process-integrated, virtual and interactive product configurator in the new and already proven next-generation CPQ software solution SAE Sales and SAE Interactive Motion Engine (SAE IME).

Product variants, machine and plant systems can thus be configured in an interactive virtual reality. In symbiosis with the SAE applications for offer management SAE Sales and variant data management SAE Developer, a holistic system is created for every company (more about the SAE product solution offering in the E3 cover article "One step ahead").

And as already stated: IT or CAD specialist knowledge is not required when sales teams use SAE-IME. Thus, the sales department remains anchored in its core competence, selling, and is perfectly supported with particularly innovative SAE solutions.

Furthermore, SAE IME is based on a long experience of SAE in the field of CPQ software with the use of ERP systems (SAP ERP, SAP S/4 Hana) as well as on the competence know-how in the field of 3D configuration.

Digital twin

The Interactive Motion Engine (IME) is effectively a world first and works through a symbiosis of ERP master data, design data, configuration, pricing and virtual reality.

This generates the Digital Core, which is important for all 4.0 activities. The digital twin generated is a virtual image of the configured product that accompanies the entire product life cycle as a specific product digital core. This data source serves efficient after-sales management, such as technical service and maintenance.

CAD and 3D visualizer

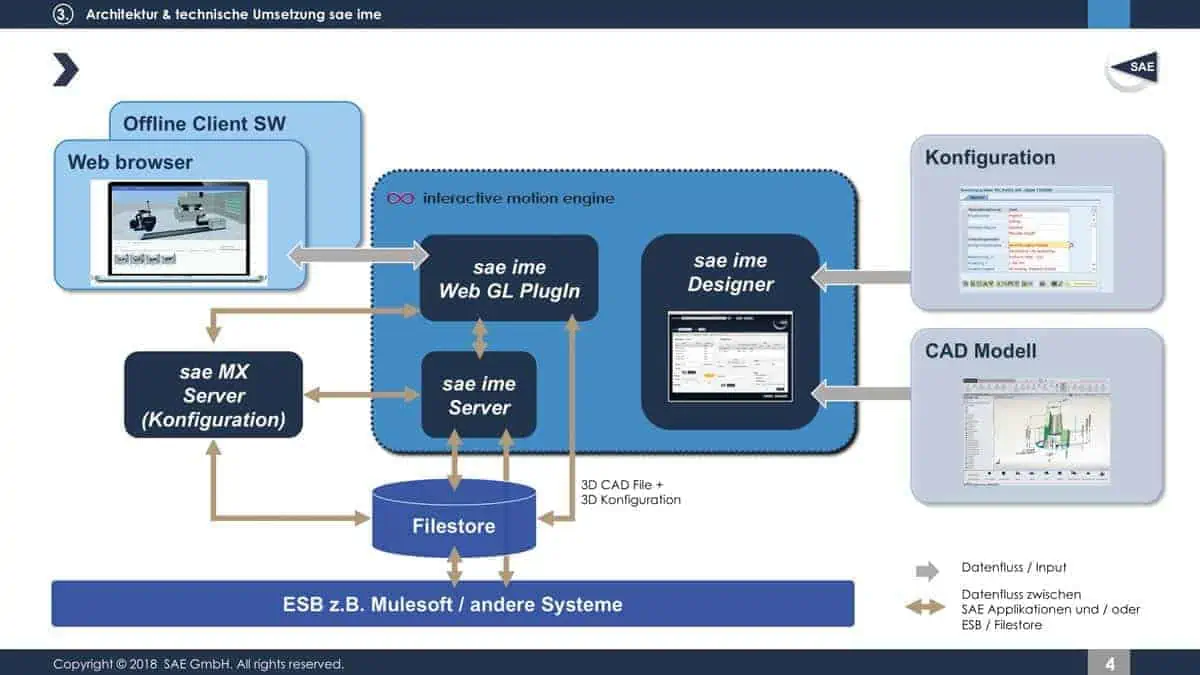

The core or basic element of the SAE Interactive Motion Engine is a so-called digital twin, which is automatically generated in the SAE application from the CAD design data.

A separate data format (ime format) is generated that is cloud-compatible. Product management designs the variant characteristics and the functionality of the product in a customizing process.

This customizing level of the SAE Interactive Motion Engine ensures an agile sales process. In terms of performance and know-how security, it is important to know that the digital twin of a complex CAD model in SAE-ime format now consists only of the relevant sales shell.

After marrying dependency knowledge and set of rules from engineering, the 3D model can firstly be operated and configured by non-experts and secondly ensures the security of the design data that is critical for competition, as it is not given outside.

It should be explicitly noted that the SAE Interactive Motion Engine is neither a classic 3D visualizer nor a generator of elaborately created individual models.

Object dependencies from ERP systems are stored in the SAE Interactive Motion Engine. What's more, there is complete process integration with CRM, PIM or SAP systems. The generated SAE data format makes the data web-capable, both CAD data and, for example, variant master data.

This means that relevant SAP ERP LO VC data also has a (necessary) web capability. Plus point: This means that IME can also be used as a cloud solution (worldwide).

Whereby the SAE solutions have always been designed for international use (with specific country pricing). As a result, with IME, (global, international) sales teams are able to configure or present offers live and interactively; with the creation of interactive virtual reality models (with computer generated reality) and without CAD knowledge. Which brings a completely new and motivating sales experience. For the seller, but also for the buyer.

Fully dynamic quotation processes

Also important: All SAE applications work symbiotically with ERP and CRM systems. The generated, proprietary SAE data format makes all design and sales data from the respective systems web-enabled.

With SAE applications, for example, relevant SAP ERP LO VC data becomes web-enabled and can be used in a virtual reality environment. Plus point: SAE applications have always been designed for international use, e.g. with specific country pricing and offer document management, and are used in over 50 countries.

A new feature for sales teams is the ability to use IME as a CPQ component to perform feature assessments together with customers directly on the model. This takes the form of fully dynamic interactive virtual reality motion simulations as part of the quotation process with ERP integration.

Regardless of this, control takes place on the basis of degrees of freedom and existing object dependencies. Likewise, configurations are managed because a stored set of rules is used as a basis.

No specifically technical and safety-sensitive CAD data with design details or development know-how is used. Sales teams can virtually generate complex product models/variants on their own from on-site thanks to SAE IME - but without having to involve a (CAD) development department at a company headquarters again and again for quoting purposes.

On top of that, queries that are often made between sales and development simply become obsolete. The benefits of the CPQ solution are obvious: quotation processes are accelerated considerably and quotation costs are reduced, in some cases significantly.

SAE Interactive Motion Engine

- Real-time interactivity between configuration and moving 3D model

- Design complete plant systems without CAD know-how Control based on degrees of freedom and existing object dependencies

- Characteristic value assignment directly in the model or in the configuration overview

Configuration options and model behavior can be conveniently customized by the specialist department, e.g. product management - Fully dynamic motion simulation

- Highest data security: database without technical CAD data

- Data transfer to ERP systems such as SAP S/4 Hana or CRM systems such as C4C or Salesforce

- Complete cloud capability of the sales solution