Data Management—Protecting the Crown Jewels

The first blueprint of a General Electric-owned steam boiler is over a hundred years old and just one of over ten million PDF documents on boilers from various eras, series and designs. These technical documents do not only hold historical value, but are also extremely valuable intellectual property that must be protected against loss and theft.

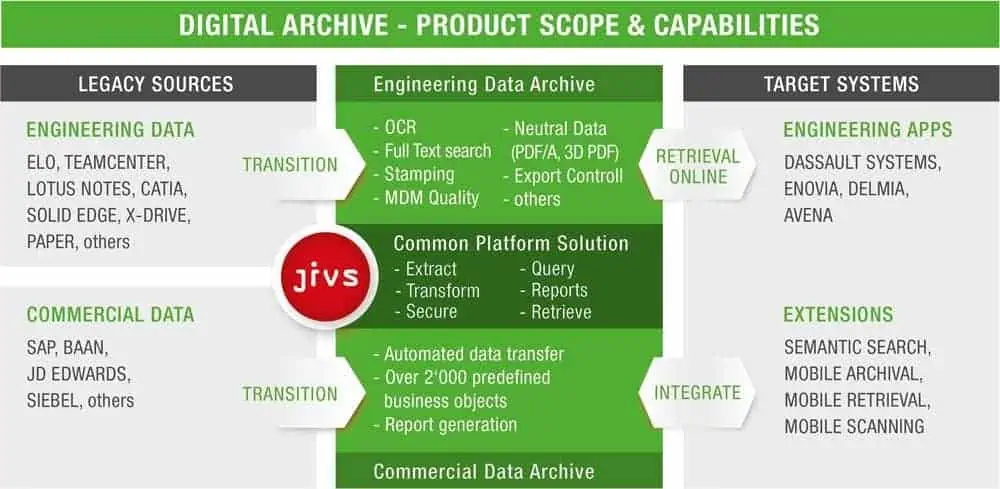

This realization provided the spark for a central information management project including the decommissioning of legacy systems. In a large-scale initiative, archives of boiler documents—mostly available on paper—were put on record worldwide and digitized as PDF scans. At the same time, they were stored centrally and securely. After all, crown jewels belong in the safe—which in this case is called JiVS at GE Power, the company’s energy division based on fossil fuels, and is a product of Swiss company Data Migration Services.

General Electric has made industrial history – not only because of its countless inventions and their effects on economic structures and entire societies. It is true that modern life would be hard to imagine without GE aircraft engines, its medical-technical equipment and systems for classical, renewable and small-scale energy generation. However, beyond the inventions, the company’s history and success have been marked by countless acquisitions, mergers, sales and spin-offs of companies and business units.

“That’s what happened when GE acquired Alstom in 2014,” recalls Peter Thomas, Technical Product Manager at GE Power, who is responsible for securing and managing development data and documents and introducing the latest IT innovations. “Because of competition law, part of Alstom had to be spun off and went to an Italian company.” However, that also meant neatly separating the business documents and technical information that was accumulated over decades in the Alstom heritage in order to avoid knowledge loss and -outflow—quite the Herculean task.

Heterogeneous, complex, expensive

Unlike business data in ERP systems, technical data and documents from engineering and also service, including maintenance and repair, are generally only partially digitized—according to estimates at similar companies with a long history such as GE Power at a rate of around 20 percent.

As IT developments and digitization progress, that rate is increasing sharply. For historical reasons, the remaining information produced before the IT revolution of the 1980s is still available on paper, picture cards or microfilms and is distributed across local archives in various countries. The digitized information is also often scattered across different locations and countries and can be found on shared drives, in application-led databases and document management systems.

This heterogeneity of data sources, databases and applications is typical for large companies and their historically grown IT environments. GE is no exception. The approximately 270,000 employees worldwide work with over 10,000 different applications.

“Although there are few systems still in development at GE, the basic problem remains. The information is distributed and available in different formats,” explains Peter Thomas, stressing: “From a company‘s perspective, this has serious consequences. We are talking about nothing less than the intellectual value chain in which the most valuable assets are created and these are the foundation of the engineering systems.“

Centralization and standardization is the magic formula for mastering this heterogeneity, affecting both the system landscape and processes. In many cases, it is not only the different GE divisions and acquired companies that operate differently, but also the locations and various units of one and the same business segment. To change this situation, GE Power’s Chief Engineers, who are responsible for unifying the global development process, launched an initiative to homogenize the system environment as part of the Alstom acquisition.

What happens to legacy applications?

With every harmonization and conversion to a uniform central system, the question immediately arises what is to happen to legacy applications and the underlying databases and inventories.

“The idea of switching off many different legacy systems and replacing them with a central application is immediately obvious in this context, is simple and, for this very reason, so captivating. However, putting this idea into practice is a completely different, much more difficult matter,“ warns Peter Thomas. “Because not only applications do have a unique lifecycle, but also the data and documents created and processed in them. If you want to shut down systems, you have to ensure that the information is managed independently of the applications.”

Dissolved, clean, compliant

By separating the application and information layers, data management like this differs fundamentally from the alternative archiving approach. On the one hand, the extracted data and documents must still be usable in the new application landscape. On the other hand, not only the information itself but also its business context must be preserved. The latter is particularly important for legal reasons.

Energy generation and supply plants are subject to strict, and in some cases divergent, regulation in all countries. Because of the longevity of these systems, all relevant information, from construction plans, parts and materials used, through permits, to maintenance and repair documents, must be stored in an audit-proof manner for several decades.

As a rule of thumb, the retention period is at least thirty years. In the case of nuclear power plants, that periods can be fifty years and longer. In addition, many components are subject to export controls in the energy sector. For this reason, associated documents such as building plans must not be accessible in all countries. Some may not leave the site, for others, official permits are mandatory in order to be able to access them.

“In practice, we have to be able to prove quickly which component was installed when, why and by whom. At the same time, we must ensure that the correct export control classification is assigned to all relevant documents. We are talking about far more information than just the construction plan of the single part in question,” says Peter Thomas. “This complete package of data and documents is usually only available in the original application, access is regulated by clear authorizations. To be able to shut down that application, we must therefore ensure that the additional data is transferred completely and in the correct context with the documents to the central information platform”.

The maintenance of this metadata as well as the master data for documents is therefore an essential part of the project to shut down legacy systems at GE Power. Only if this data is properly maintained, queries are possible for legal and, even more so, for business reasons.

This is the only way for maintenance teams or quality managers in example, to have all documents relating to damage to a gas turbine in a power plant in a specific Asian country displayed at the touch of a button. If quality managers find that this damage is more frequent than just in that single plant, even older construction plans should be available to developers and engineers to make improvements to the damaged parts in question.

This must of course be possible in the new central system. Data and documents originating from decommissioned systems must therefore be converted into formats that can be used in the succeeding systems. Conversely, documents from new applications will become obsolete at some point too and must therefore be stored as well in the central platform for information management.

Legally compliant platform

“This is the only way to close the information management cycle,” stresses Peter Thomas. “The catalogue of requirements for a legally compliant platform for information management is high accordingly. Fortunately, there has already been a similar project to standardize the system landscape in the ERP environment.”

His colleagues had already examined the market and corresponding offers. JiVS proved to be the only solution that was able to meet all requirements for a legally compliant, context-dependent management of the entire information lifecycle for both structured and unstructured data.”

The first project in the area of Product Lifecycle Management (PLM) from 2014 to 2016 at GE involved detaching over ten million PDF documents on steam boilers, which were stored at six different locations in different systems, including a PLM application in Ashby in Great Britain and a document management solution in Stuttgart. All documents were to be migrated to the central JiVS platform, which is implemented at the GE-Power location in Baden.

Available, reliable, reusable

“This was the opportunity to design and implement an ideal process for information migration,” reports Peter Thomas. “The starting point was to distinguish between active and inactive information.” Only the active ones that are needed in daily work should be transferred to the new GE Power PLM central system. Inactive data and documents, on the other hand, which are only occasionally relevant for business or must be kept exclusively for verification purposes, were transferred to JiVS.

After the data and documents had been extracted, the master data and metadata had to be maintained, cleaned and, if necessary, transformed. At the same time, the documents were indexed in several languages using OCR recognition to enable full text search. Neutral file formats were defined for reuse, PDF and TIFF for documents and STEP and 3D PDF for drawings or plans.

Finally, a kind of stamping system was implemented in JiVS with which every call to a document from JiVS could be traced, in particular in order to fulfill the requirements of export control. The stamps are used in the same way when documents are transferred from the live system to JiVS. Basically, the whole thing resembles a classical library system, where every new addition as well as every loan is recorded without gaps.

Since September 2017, both the system in Stuttgart and the solution in Ashby have been completely replaced after the documents had been migrated to JiVS in full. As these included management documents and even personnel files, access to them had to be severely restricted. After all, in the case of personal data for example, the strict requirements imposed by the GDPR must be fulfilled.

“The project was a complete success,” says Peter Thomas happily. “All documents are still available worldwide and can be searched for in English, French, Spanish and Italian. Users can be sure that the content is correct and consistent. They can also use them in the new environment if required. Available, reliable, reusable, that is the value of information for a company.”

Already during the project, Peter Thomas received further requests for migrations and system shutdowns. These included two initiatives to replace product data management (PDM) systems in Switzerland and Sweden. In the course of the accompanying migrations, the procedure model for data transfer was further refined.

On the one hand, the CAD drawings stored in JiVS should be reusable in the latest CAD environment, i.e. CATIA 5, outside the central PLM solution. Secondly, a new category of migrated data was created for information that could not yet be transformed and normalized due to time constraints.

Nevertheless, auditability during migration to JiVS is guaranteed because the unchanged transfer from the legacy systems is completely documented. Both of the legacy PDM solutions in Switzerland and Sweden are to be shut down by the end of 2018. Only the last two released versions of the affected documents are transferred to the central PLM system for daily work.

Efficient, effective, valuable

The advantages of a central, company-wide platform for information management are obvious: With the right backup strategy, data and documents are protected against loss. Authorizations and control prevent unauthorized access, whether accidentally or with intention.

In the case of reorganization through acquisitions and sales, the information assets can be separated or merged with much less effort than in heterogeneous IT landscapes or in the paper world, since there are complete records available. Legal requirements and other obligations to provide information and proof can be fulfilled at the push of a button. In addition, information can be retrieved, searched and used in current business cases within seconds worldwide. This is both efficient and effective.

Necessary persuasion

“Yet we have to convince business users and those responsible for applications time and again. My team and I are always confronted with the question why these advantages would not be achieved much easier and, above all, faster if all the old information assets were simply transferred to a new, central environment,” complains Peter Thomas. His answer is always the same: “Because it’s too expensive in the long run.”

Of course, it takes longer initially to clean, normalize, enrich and, if necessary, transform the information before it can be reused. However, this is the only way to preserve the required business context of the information for business and legal purposes independently of the legacy systems—so that these legacy systems finally can be switched off.

Economic advantages

With JiVS, GE Power saves on average 80 percent of operating costs compared to keeping legacy systems active. In addition, the reduced search times and the resulting contribution to value creation—those who find construction plans faster can also write more maintenance orders—add up to several million Euros per year for 50,000 employees in this business unit alone. “Our information management based on JiVS is much cheaper than an archive, but as valuable as a treasure,” concludes Peter Thomas.

His plans however, go much further: “Considering that the lion’s share of information still exists on paper, it quickly becomes clear that the potential of our central information management is far from being exhausted.“

He estimates that around 90 percent of the documents in the paper archives can be completely digitized. The rest are documents that have a historical value and should therefore continue to be preserved in their original form, as well as documents whose legal validity depends on signatures that have been produced once and cannot subsequently be digitally reproduced. Here, too, the financial argument is decisive.

The expenditure for the paper archive in Baden alone, which contained approximately 16 kilometers of shelfs—50 million documents—adds up to considerable maintenance costs for archivists and rent each year. In addition to file maintenance, the financial impact of physical security requirements imposed by law for archive rooms and buildings cannot be ignored. After all, the files must not only be effectively protected against burglary, but also against fire and flooding.

“I have calculated the profitability of digitizing the paper stocks in the engineering department for three archives and thereby determined an almost six-digit savings sum per year in US dollars,” says Peter Thomas.

Spiritual and physical world merge

In the long term, however, he sees an even greater advantage than cost reductions. With the conversion of the paper archives to JiVS, the development would achieve a similarly high degree of digitization as the transaction-oriented world of ERP.

“If development and ERP could access the same pool of information, the intellectual and physical value chain could be merged. As a group, you would then be as agile and flexible as the medium-sized businesses rightly praised for this quality. In short: the right people could then access your crown jewels at the right time and in the right context, thus further increasing the treasure.”