Industry 4.0 for every machine

The machines of the HF Mixing Group are used very successfully mainly by tire manufacturers, but also by other companies producing technical rubber goods. HF Mixing Group is one of the hidden champions and has customers all over the world who process rubbers into rubber compounds.

IT-defined machines

"In the typical case, our customers' production runs around the clock"

explains Daniel Büdenbender, software developer at HF Mixing Group.

"This results in high demands on the machines and on the software in the machines."

In the meantime, software, IT and automation technology account for a significant share of the manufacturing costs of a machine. At the HF Mixing Group, for example, a database is part of the machines in addition to the control software.

The software includes production control and weighing of the required raw materials. This means that the data also contain a considerable amount of intellectual property. For the control of complete mixing rooms with all aggregates, such as those built by HF in Freudenberg, the recipes, the data for production control and the machine and operating data are stored in a database.

Because the machines at HF customers usually run around the clock, the highest demands are also placed on the integrated information technology.

Büdenbender:

"We have customers where the machines run 24 x 7 and have a life cycle of up to 20 years. No IT can manage that, but the database servers still have to be highly available. It's a vicious cycle."

As a mechanical engineering company, HF Mixing Group was looking for an easy-to-implement solution that would improve the high availability of its databases. This should be easy to use by the customers.

"Our goal was to find a solution with user instructions that fit on an A4 sheet of paper"

Büdenbender explains further.

With the support of a consulting firm, they found what they were looking for with the software solution DBShadow from SAP partner Libelle in Stuttgart.

24 x 7 requires highly available IT

The requirements for the high availability solution sound simple, but in sum they are complex. Simple and easy to use is only part of the requirements. At the same time, the solution should be so cost-effective that it does not make the machines unprofitable when delivered.

This also includes the fact that no additional personnel, such as a database administrator, are needed to use the solution. Plant managers and production managers are certainly very IT-savvy today, but it may still be necessary for a worker to lend a hand as well.

Time shifted mirroring

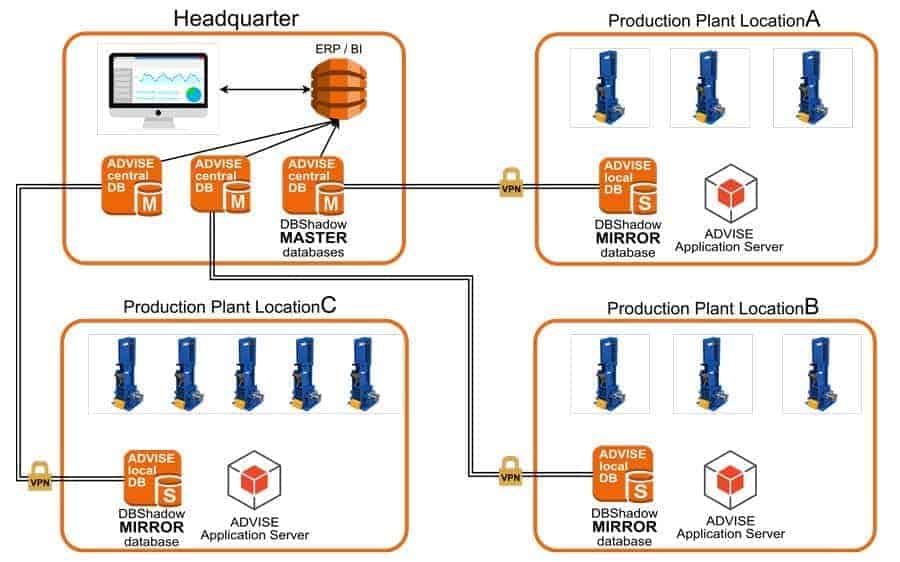

The Libelle solution DBShadow is an easy-to-use solution for time-shifted database mirroring. The functional principle is patented: After an initial copy, all changes to the production instance of the database are stored in a cache called a funnel.

Only after a defined time interval or in the event of a malfunction are these changes transferred from the hopper to the mirror system. This means that the mirror system runs behind the productive system by the set time offset, but all transferred productive changes are already physically in the time funnel on the mirror side.

This results in two significant effects: In the event of an erroneous data loss, the clock can practically be turned back, since not all changes from the hopper have yet been executed on the mirror system.

The second major advantage is that in the event of a malfunction, it is possible to switch over to the mirror system very quickly. The mirror system is thus switched to the productive system very quickly, so that production is not interrupted in the event of a failure.

High availability

In the manufacturing industry in particular, fire, water, dirt or leaking operating materials can disrupt information technology. If the IT fails, the machine also stops. That is why IT alone should not provide a single point of failure for production.

Especially in the raw material processing industry, it is often not the actual downtime of the plants that leads to high costs, but the cleaning of the plant when restarting and the adjustment of raw material and product.

Combining the high availability of the mixing plants with a high availability solution for IT gives HF Mixing Group an important competitive advantage. In the event of a malfunction, the plant managers or production managers switch to the database mirror.

However, local data storage at each individual machine would be uneconomical, which is why the database servers used represent a central database instance for each site.

Duplicate snapshot

Many data high availability solutions target technical failures. Therefore, data is simply duplicated via snapshot. However, databases can also be filled with incorrect data due to controller errors, which may not even be noticeable for a certain time. Incorrect data created in this way has accordingly spread across snapshots and raid drives in no time at all.

In production environments, there is also a risk that errors in the database may not be noticed immediately if machines - and likewise the servers that support these machines - are involved in processes that run largely independently.

Errors on the database servers must then be reported by automatic notification not only to the responsible employee. They must also be able to remotely maintain the database server. The Libelle solution was also able to score here.

Success confirms concept

Several dozen licenses of DBShadow are implemented in the mixing plants at HF Mixing Group customers.

"We are more of a control body in these cases".

says Büdenbender.

"For example, at the customer's request, we check the database repair and then perform the switch back to the production system as a service."

The service department receives messages about how often DBShadow takes hold and switches productive operation at a customer to the mirror.

The machine builders estimate that DBShadow is used about ten times a year by the users and prevents costly production downtimes - the high availability of the database servers proves its worth in production, especially in just-in-time manufacturing.

In the future, the HF Mixing Group also wants to be even more flexible in this aspect. In addition to the solutions from Oracle, other databases are also to be offered in order to meet customer requirements even better and to be able to use the machines even more flexibly.