Flow Metrics Offer KPIs for DDSCM

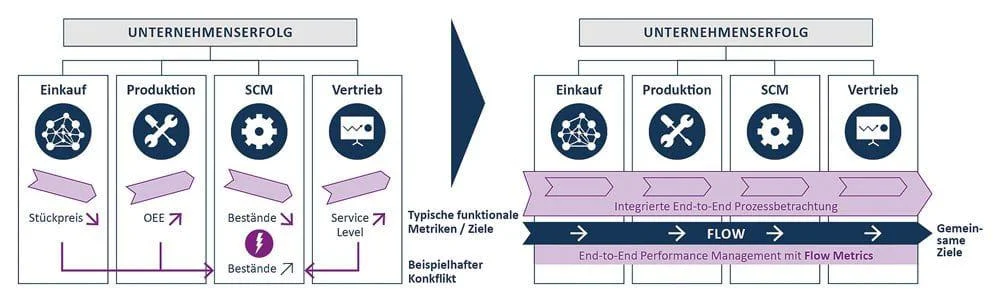

You can find the typical conflict of interest between OEE maximization vs. inventory reduction vs. service level optimization in almost every supply chain. Individual, mostly cost-based targets of independent functional departments lead to silo-like optimization and mutual interference within the organization due to contradictory and misleading target values for KPIs.

The reason for this is usually a lack of understanding that the criteria for what makes information relevant, differs in the operative, tactical and strategic planning area. Forecasts, for example, are required for long-term planning, but actual customer demands are decisive in the short term.

The consideration of fixed costs, for example via key performance indicators such as OEE, is also relevant in strategic planning, but leads to sub-optimal decisions in the operational counterpart. Optimal control of the supply chain therefore requires conflict-free key performance indicators that are tailored to the respective decision-making process.

Variability and silo optimization

In DDMRP, all decisions at the operational level are made in a way that enables them to promote the flow of relevant information and materials. Flow was recognized as the most important and highest goal that is conflict-free. In turn, flow neither promotes variability nor silo optimization. Therefore, Flow Metrics are key performance indicators that consistently support the flow of relevant information and materials.

For this purpose, only information relevant to the respective decision-making process is included and conflicts of interest are consistently eliminated. Flow Metrics take into account, for example, that neither revenues nor full costs are relevant in day-to-day operations, but rather the throughput—especially in the case of bottlenecks in the supply chain.

Freedom from conflict

Freedom from conflict

The transition to flow-based performance management does not necessarily dictate that all previous KPIs need to be replaced. However, potential conflicts must be eliminated, and the availability of relevant information ensured at all stages of the decision-making process. Camelot has established a structured approach and, based on the experience from various projects, put together a set of established Flow Metrics. These are also an integral part of all SAP-based Camelot solutions for Demand-Driven Supply Chain Management, where they optimally support decisions through intuitive and target-oriented visualizations.