Digital disruption and transformation

![[shutterstock: 1146107879, Blue Planet Studio]](https://e3mag.com/wp-content/uploads/2021/01/shutterstock_1146107879.jpg)

Recurring crises and trade barriers pose challenges to companies' international supply chains. All the factors of a dynamic and networked economy increase the complexity and demands on supply chains. Individual customer requirements, short delivery times, fierce competition and the growing number of links involved in the chain - all these factors are causing supply chains to shed their linearity.

Instead, network-like structures are gradually emerging, making goods flow systems increasingly fast-moving, agile and flexible. In view of this multidimensionality, companies today must position themselves more dynamically in order to meet the requirements and expectations of their business and organizational environment. This not only affects multinationals, but also medium-sized companies, which are just as dependent on international trade and sourcing to ensure their competitiveness.

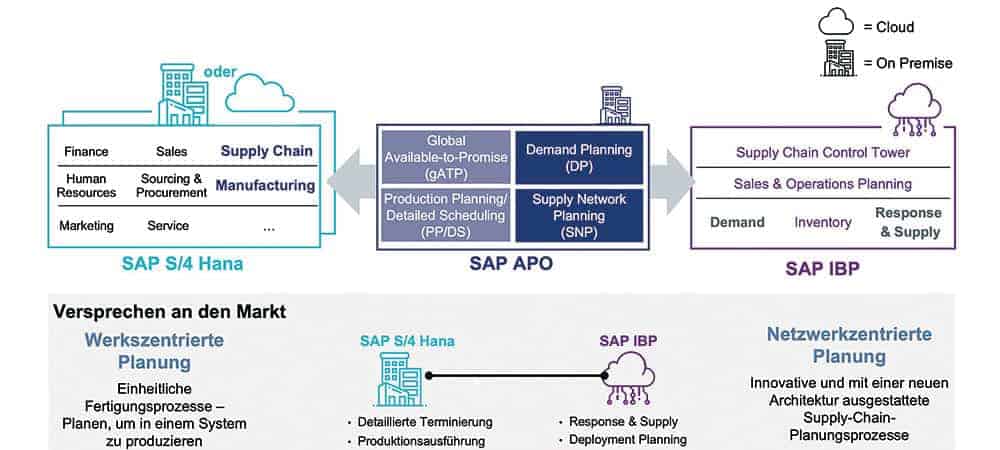

All of this places demands on a modern supply chain and IT infrastructure that SAP APO (Advanced Planner and Optimizer), which was developed at the end of the 1990s, can only fulfill to a limited extent. For around five years, SAP has therefore been developing successor products such as Integrated Business Planning (IBP), which will successively replace APO-based solutions, embedded PP/DS (Production Planning and Detailed Scheduling), a new material and resource availability check (aATP, advanced Available-to-Promise), store floor integration via SAP Manufacturing Execution (ME) and the Digital Manufacturing Cloud.

Embedded and Advanced

The APO PP/DS functions for finite production planning and optimization as well as the availability check (aATP) are integrated in S/4 Hana. Thus, S/4 has a fully integrated Advanced Planning System (APS) for finite planning of production capacities. From Consilio's point of view, this is a serious advantage for an implementation. The aATP has been newly developed as part of S/4 and offers comprehensive options from order checking and confirmation to quota allocation and production checks. Companies often look for benefits and reasons to move to S/4. From Consilio's point of view, ePP/DS and aATP provide comprehensive reasons for process improvements.

With IBP, SAP has placed the Demand Planning and Supply Network Planning components on a new technological footing and equipped them with enhanced functions. SAP Integrated Business Planning (IBP) is a web- or cloud-based SCM application that includes functions for demand, procurement, distribution and inventory planning and was technically implemented on the Hana database platform. An on-premises version is not available. Similar to APO, IBP also consists of several modules which, however, are not necessarily congruent with the APO modules.

IBP for Sales and Operations Planning is a business planning process driven by senior management that evaluates and revises time-phased forecasts for demand, supply, product and portfolio changes, strategic projects, and the resulting financial plans for the medium- to long-term planning period.

IBP for Demand combines "traditional" mid- to long-term planning based on statistical methods with the ability to run more accurate demand sensing models to improve forecast accuracy for the short-term planning horizon. The solution combines automated, exception-based planning processes with manual planning capabilities based on the speed of Hana and a user-friendly Microsoft Excel interface.

IBP for Response and Supply enables rapid adaptation to changes in demand, taking into account the full supply chain model, and simulates production, distribution and procurement schedules to meet customer requirements in a constrained or unconstrained mode. Integrated business planning for response and delivery generates what-if analysis to provide insight into potential scenarios.

IBP for Inventory positions inventory in the most appropriate locations to absorb forecast errors, demand variability, and supply uncertainty while meeting customer service objectives. The application optimizes inventory targets using a series of algorithms to achieve these targets at the lowest possible inventory cost for all locations throughout the supply chain.

Optimization and detailed planning

With this new solution architecture, the ERP system S/4 in particular has been massively upgraded for production optimization and detailed planning. There is now finally a planning solution in which material, machines, personnel and other production restrictions such as tools can be finit optimized from a system solution. In order to optimally allocate production resources, either automatic or manual setup optimization, sequence formation, etc. can be carried out with consideration of personnel, material and operating resource availability. S/4 supports not only classic finite planning scenarios, but also industry-specific scenarios such as model-mix, block, and campaign.

Planning.

The integrated approach in S/4 makes it very easy for companies to successively implement finite production planning. This solution massively reduces IT system architecture costs and implementation and integration efforts. The selection of which of the business objects such as sales orders, planned independent requirements, inventories and production orders participate in production optimization can be easily set via customizing.

The production areas for which production optimization is to take place are also set directly in the application for materials, work centers and bills of materials. Thus, an application for individual production areas within a plant is also possible.

Looking at the SAP roadmap for production optimization (ePP/DS), it is evident that SAP is investing massively in the expansion of detailed production planning and optimization.

Under the name advanced Available-to-Promise, SAP is reorganizing the availability check in S/4. The aim of aATP is to provide intelligent product availability checking in real time for sales, planned and production orders. It offers scalable Available-to-Promise logics for managing large transaction volumes, flexible allocation functions and also includes backorder processing with intuitive priority classification as well as interactive exception handling.

Here, too, the advantages and business benefits of the Hana in-memory database are clearly evident. In addition to the classic procedures such as ATP checking and quota allocation, other options are available, such as: Alternative Based Confirmation (ABC). Here, alternatives can be checked if the availability for a requirement in a material-plant combination is not sufficient.

Execution and integration

Excellent planning also requires first-class execution. With SAP Manufacturing solutions, planning results can be integrated and embedded in manufacturing processes and Industry 4.0 principles can be implemented with a single source of real-time information. Planning is required for coordination of resources and production. It covers the manufacturing cycle from production order to order fulfillment.

Digitalization increases the efficiency and flexibility of manufacturing and harnesses the Industrial Internet of Things (IIoT). The SAP Manufacturing Execution solution consists of SAP ME (Manufacturing Execution), SAP MII (Manufacturing Intelligence and Integration) and the Digital Manufacturing Cloud. SAP Manufacturing is a powerful, scalable manufacturing solution from the machine and plant level to the enterprise level. It helps global manufacturers manage and control their manufacturing and production operations.

From many years of experience, especially in the context of connecting third-party APS and MES and the usually associated complex consolidation, Consilio is convinced that SAP provides a well-integrated platform from sales planning to production planning and optimization to manufacturing as well as efficient control of the store floor for companies.

SCM trends 2021

Individual: From mass production to customized production (make-to-order, engineer-to-order).

Connected: The supply chain connects employees of a company with companies within the network, creating a synchronous planning process across customers, suppliers, contract manufacturers, logistics providers, and so on.

Predictive and intelligent (Predictive): Using intelligence and information to create transparency across the supply chain. Predict where vehicles are and whether they will arrive on time or late based on traffic patterns.

Automated: Technologies such as the Internet of Things (IoT), machine learning and artificial intelligence (AI) enable access to real-time data across the supply chain. This helps companies leverage this information to increase agility and resilience across the supply chain. Employees should be freed from routine tasks and be able to focus on troubleshooting.

Dynamic: Brexit, trade dispute with the USA, Corona, etc. - all these events make it necessary for companies to be able to simulate changing market situations in their supply chain at short notice and change them dynamically if necessary. Only with integrated supply chain planning is it possible to react with fast planning cycles.