Shortening The Process With DDSCM

Many companies in the process industry are already convinced of the benefits of Demand-Driven Supply Chain Management. However, when it comes to implementation, they often face the challenge of applying theory to the practical complexity of their supply chain. Typically, there exist numerous limitations and challenges that need to be taken into account when attempting to increase plant availability and improving overall plant efficiency.

If anything, most companies hence only start with small DDMRP pilot projects in distribution. Since usually no support system is available, complex Excel tools are used. This in turn makes it difficult or even impossible to transfer the advantages achieved in these small pilots to the entire organization. The scalability of these homegrown add-ons is therefore questionable at best.

Lean planning

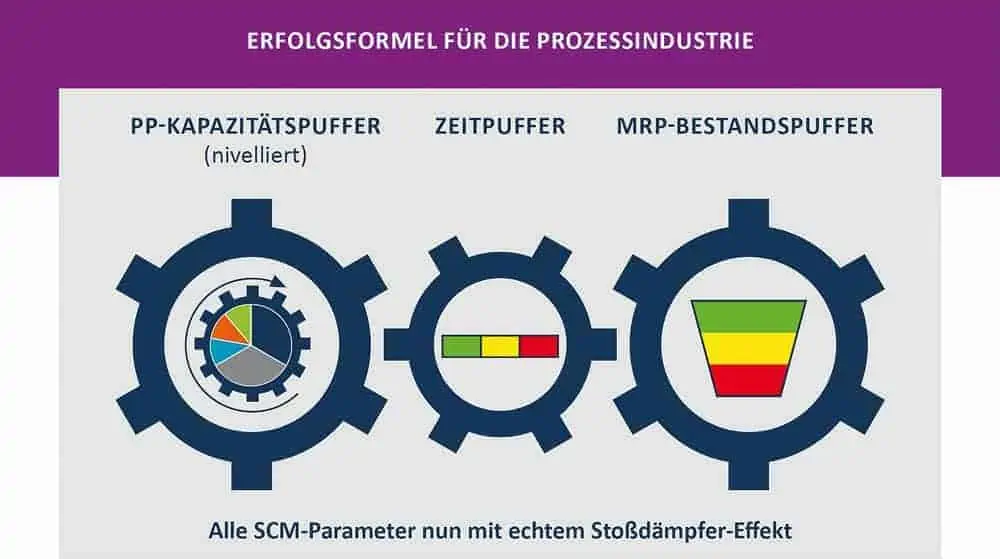

The SAP-based Camelot Demand-Driven Lean Planning Suite (CLS) is a completely integrated solution that supports companies in the process industry in meeting these challenges. The Camelot Demand-Driven Lean Planning Suite is available on SAP S/4 Hana, SAP Integrated Business Planning (SAP IBP) and SAP SCM. In addition to Demand-Driven MRP (DDMRP), the software suite also includes Demand-Driven Rhythm Wheel Planning (DDRWP), a concept for smooth production planning that is highly regarded as a best practice in the process industry today. DDMRP (available on SAP S/4 Hana, SAP IBP, and SAP SCM) reduces the variability of supply and demand by using the inventory in the system as a buffer and replenishing it based on actual consumption rather than forecasted demand.

Production then follows the DDRWP’s repetitive cyclical production approach (available on SAP S/4 Hana and SAP SCM). In this way, production is leveled over time, demand fluctuations on the upstream stage (for required components) are reduced and the visibility and reliability of relevant signals in the supply chain is increased. Production requirements such as batch sizes, campaigns and optimal sequences are taken into account. With the Demand-Driven Lean Planning Suite, Camelot offers a holistic and integrated solution package—particularly for the process industry—and thus supports the introduction of a Demand-Driven operating model. The suite is also available as a cloud solution.

Bottlenecks

The integration of DDMRP and DDRWP in the Camelot Demand-Driven Lean Planning Suite has the following advantages: DDRWP parameters such as cycle times, production quantities and campaign frequency are used in design and parameterization to automatically determine the level of DDMRP inventory buffers and to align them with production requirements and lead times. During production planning, the projected inventory buffers are calculated based on the current demand situation and can be taken into account to set alerts and/or prioritize for automatic intervention when bottlenecks occur.