JiVS IMP Demands Freedom for Product Data!

Manufacturing companies in general and machine and plant manufacturers in particular face a special challenge when they introduce new generations of software. Not only do they have to ensure a legally compliant and long-term solution for the storage of their legacy data. Rather, they are also responsible for storing their construction plans, design drawings, images and documentation on the parts and materials used, approvals and documents on maintenance and repairs in an audit-proof manner for several decades.

As a rule, the retention period is at least thirty years, and fifty years or longer in the case of nuclear power plants. In addition, many components are subject to export controls, for example in the energy sector. For this reason, associated documents such as construction plans may not be accessible in all countries. Some are not allowed to leave a site, while official permits must be applied for in order to access others.

Linking: Data and documents

Companies must be able to prove why which part was installed when and by whom. At the same time, they must ensure that all relevant documents are assigned the correct export control classification. This is far more information than the blueprint of the part itself with which it is associated. This complete package of data and documents is usually only available in the original application, and access is regulated by clear authorizations. In order to be able to decommission such applications, companies must therefore ensure that the data, including metadata, can still be accessed in full and in the correct context together with the documents.

The maintenance of metadata and document master data is an essential part of a project to decommission legacy PDM systems. Only if the data is properly maintained will queries be possible, not only for legal reasons, but even more so for business reasons. This is the only way that maintenance teams or quality managers can, for example, display all documents relating to damage to a component of a plant in a specific country at the touch of a button.

If quality managers determine that this damage occurs not only in the system in question, but more frequently, improvements can only be made to the defective parts if older construction plans are also available to the developers. Data and documents from decommissioned systems must therefore be converted into formats that can be used in the successor systems.

Decommissioning legacy PDM systems

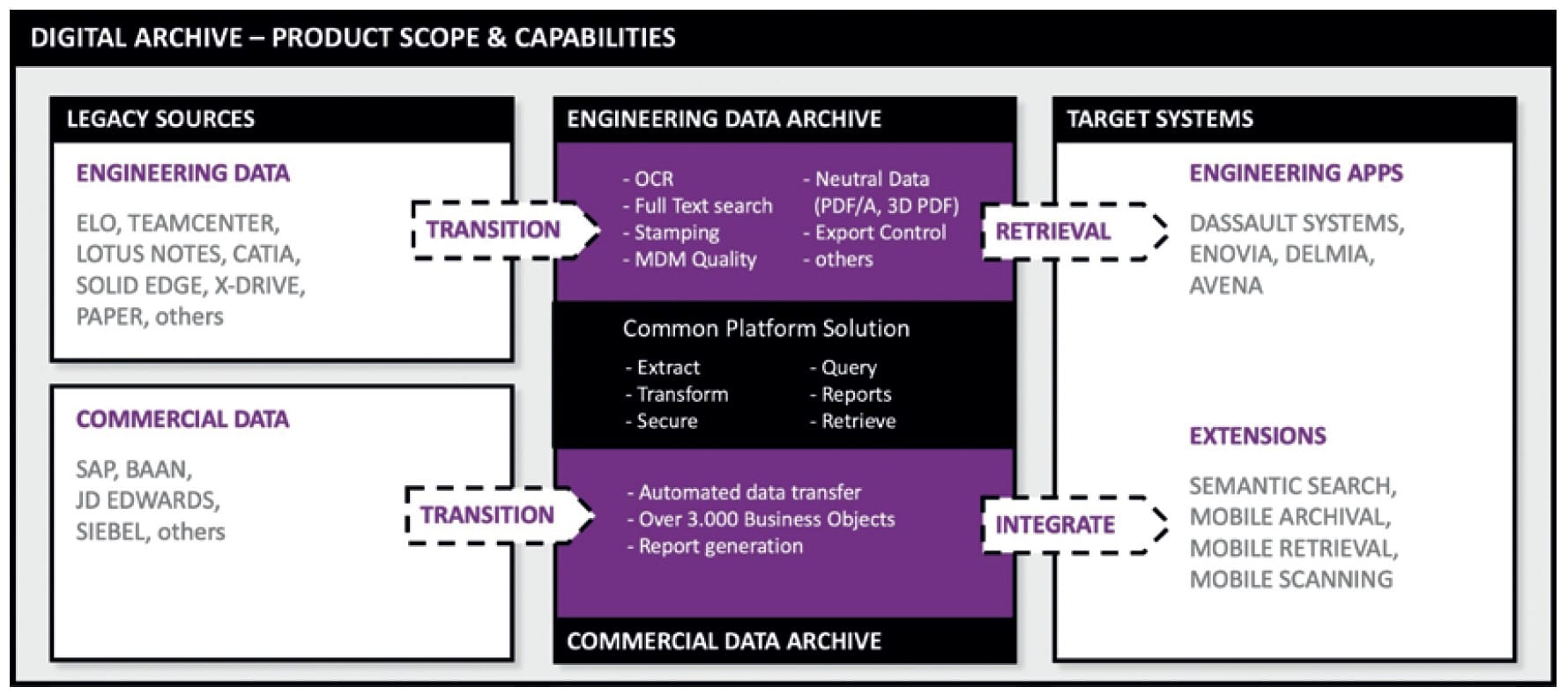

If companies decide to switch to a new generation of PDM systems and decommission the corresponding legacy systems, they need a replacement: a central, company-wide platform for information management. The advantages are obvious: with the right backup strategy, data and documents are protected against loss. Authorizations and controls prevent unauthorized access, whether accidental or deliberate. In the event of reorganization through acquisitions and disposals, the information assets can be separated or merged with much less effort than in heterogeneous IT landscapes or in the paper world, as they are fully inventoried. Legal requirements and other information and verification obligations can be fulfilled at the touch of a button. In addition, information can be retrieved, searched and used in current business cases worldwide in a matter of seconds. This is both efficient and effective.

It goes without saying that companies should cleanse, normalize, enrich and, if necessary, transform their information before reusing it. This is the only way to retain the contextual information required for business and legal purposes independently of the legacy systems so that they can be switched off.

Transformation without legacy

Manufacturing companies, and machine and plant manufacturers in particular, should manage the entire lifecycle of legacy PDM data and documents separately, i.e. detached from the outdated PDM solutions.

This requires a platform,

- with the help of which all PDM data and documents can be extracted from legacy systems within a very short time, even with high volumes,

- which enables the import and readout of scanned paper archives using OCR recognition,

- on which this data including metadata and documents, the latter in a neutral format such as 3D PDF or PDF, can be stored in a legally compliant and EU GDPR-compliant manner,

- which at the same time offers all options for further data processing such as selection, transformation and migration via the application layer to current PDM systems,

- which not only allows access to the migrated PDM information, but also to the archived PDM data and documents in the current PDM systems,

- which uses AI to suggest which business objects are required for storing and displaying data and documents such as parts lists, CAD drawings or construction plans from the legacy PDM systems and how these objects can be created,

- which builds a bridge to ERP data and systems,

- with the help of which the entire life cycle of PDM data and documents can be managed via retention management through to legally compliant deletion

- and thus enables the decommissioning of legacy PDM systems.

JiVS IMP, the platform for company-wide information management from the Swiss Data Migration International Group (DMI), is precisely this platform. As it not only archives PDM data and documents from legacy systems, but also manages their lifecycle until legally compliant deletion, it is also a product lifecycle management solution for this legacy data and documents. As a central platform for the storage, transformation and migration of all types of data and documents from ERP and PDM systems, JiVS IMP plays a central role in building a company-wide data layer, a so-called data fabric. This enables companies to manage their data and documents independently of the applications, avoid restrictions due to vendor lock-in and increase flexibility in selection.

Economic advantages

The resulting business benefits are enormous. Using JiVS IMP, companies usually save 80 percent of the costs compared to continuing to operate their old systems. In addition, the reduced search times and the resulting contribution to added value - those who find construction plans faster can, for example, write more maintenance orders - very quickly add up to several million euros a year, depending on the number of employees who access PDM data and documents in their daily work.

The advantages are even more far-reaching, as the lion's share of information in development still exists on paper at many manufacturing companies and machine and plant manufacturers. The majority of documents in paper archives can be completely digitized. The rest are usually documents that have a historical value or those whose legal validity depends on signatures that have been made and cannot be reproduced digitally at a later date. Here too, the financial argument is decisive. In addition to the file maintenance of sometimes millions of documents and several kilometers of records in the archive, it is above all the physical security requirements for the archive rooms and buildings prescribed by law that have an impact here. After all, the files must be effectively protected against burglary, fire and flooding. The savings potential is huge.

Value chains become one

The strategic advantage here is that by eliminating paper archives, development can achieve a similarly high level of digitization as the transaction-oriented ERP world. If development and ERP can access the same information, the intellectual and physical value chains can be merged. The right people can thus access the company's crown jewels at the right time and in the right context and further increase the treasure, regardless of the current applications.

Pilot project: PDM transformation on demand

Data Migration International is currently working with various companies and partners on successful pilot projects for a PDM archive based on JiVS IMP.

The aim of this solution is to extract CAD data including metadata, documents and attachments from the legacy system to JiVS IMP. The legacy information is stored there in a legally compliant manner. At the same time, the CAD drawings are converted into a neutral format such as 3D PDF and PDF and prepared together with the metadata for later search and display. At the same time, the original CAD data is transformed and finally transferred to the successor system. Developers will then be able to continue working with the original data in the new system. Together with other users, they can search for drawings and documents from the old system and display them, call up parts lists for components and export them to Excel.

If the tests are successful, the companies can gradually switch off their legacy PDM systems and store and manage their legacy data and documents exclusively on JiVS IMP. Another advantage: to keep the successor system lean, they can initially only transfer some of the legacy information, but can transform and migrate the data and documents they need at any time at the touch of a button in order to continue working with them in the operational system.