Suitable automation solution with smart system architecture and SAP Extended Warehouse Management

Transparent inventories and real-time capable processes in the supply chain as well as scalable automated solutions in the warehouse increase agility. As a holistic ERP solution, S/4 Hana offers seamless access to various current and historical data. This allows suppliers and procurement processes to be analyzed and evaluated in order to develop optimal procurement strategies from these findings and reduce risks in the supply chain. For warehouse management, S/4 offers SAP Extended Warehouse Management (EWM), a scalable solution for warehouse management and control.

Supply Chain and Warehouse

In the Gartner Magic Quadrant for WMS 2022, EWM is among the leading solutions for efficiently managing inventories and fully supporting all types of warehouses and warehouse movements. SAP EWM is particularly suitable when modern, highly flexible warehouse planning and work organization as well as far-reaching options for automating processes in the warehouse are required. All customer-specific requirements for warehouse processes - from goods receipt and warehousing to picking and shipping - can be covered and optimized with the modular EWM system. By seamlessly linking intralogistics processes with upstream and downstream transport and yard management processes integrated in S/4, users can control their supply chain holistically and flexibly.

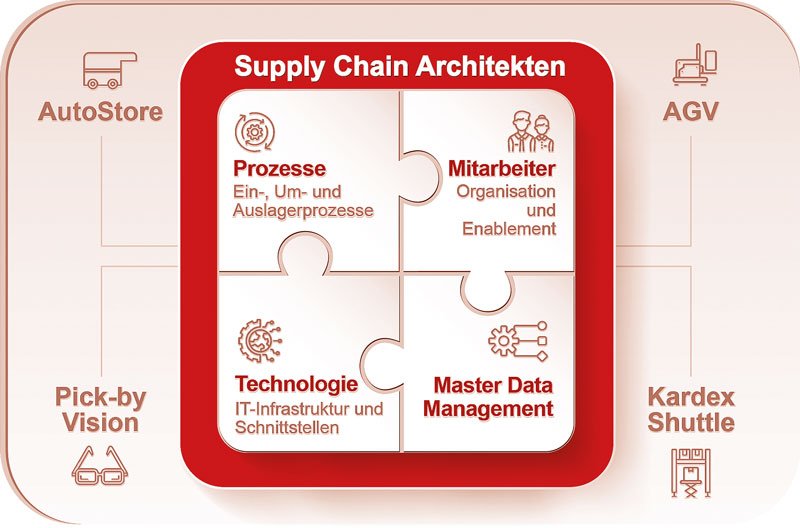

Against a backdrop of limited resources, rising labor and workplace costs, and scarce logistics space, more and more companies are implementing automation solutions in their warehouses. The market for intralogistics offers a wide range of automation solutions for internal material transport, storage and order picking as well as packaging and loading. But technology alone will not bring the desired success if it is not coordinated and interlocked with people, processes and master data management.

In order to select the right automation solution in conjunction with the WMS, the processes and the users, all building blocks should therefore be taken into account as early as the planning and conception phase and the appropriate project partners selected. Supply chain architects such as LogiPlus can help with this. The EWM consulting firm has been supporting companies for around 25 years with custom-fit concepts and solutions for supply chain optimization and digitalization. Like a general planner or architect, LogiPlus draws on other service providers with the relevant expertise from its network as needed. As EWM pioneers, LogiPlus consultants have extensive project experience in intralogistics as well as in the integration of automated trades and processes in the warehouse. In doing so, they always have a holistic view of the automation project and show various options for integrating SAP EWM with automated guided vehicles (AGVs), stacker cranes or other automation solutions such as AutoStore or warehouse lifts.

The training and enablement of the project staff and users who will later operate the system are crucial to the success of any project. Without stable and integrated processes and without involving the affected employees in the change process, the desired potential of the automation solution, such as increased productivity or shorter throughput times, will only be partially realized. Therefore, there should be differentiated training concepts and the planned organizational and process-related adjustments should be clearly communicated, for example by mapping the process flows as well as the integration and decision points.

In this context, the application of the technology must be appropriately trained in good time before and during commissioning so that the promised performance can also be achieved in ongoing operation. Here, partners such as LogiPlus can also provide personnel support, especially in the critical transition phase when changing from a manual warehouse to an automated warehouse, until the processes run smoothly. This shows how important it is to also pay attention to the provider's supply chain and logistics expertise when selecting the right software implementation partner. Experienced consultants know the challenges and pain points during commissioning and bring their know-how to bear when designing the processes and workplaces.

Looking at AutoStore as a possible warehouse automation solution: Many of the companies that are looking at AutoStore in the course of automating their small parts warehouses have SAP EWM as their Warehouse Management System (WMS) in use. When selecting the appropriate warehouse automation solution, it is equally important to consider the system's software integration capabilities and its technical interfaces and coupling at an early stage, in addition to the physical criteria, when selecting a system and vendor. AutoStore, for example, offers various standard interfaces (APIs) for direct connection of the system with the user company's WMS. In addition, the AutoStore-live simulator can be used to test the processes around the AutoStore system before the hardware is installed. Other intralogistics vendors provide a Warehouse Control System (WCS) as middleware to enable self-contained IT integration.

Warehouse Control System

With the task and bin interface, on the other hand, AutoStore provides flexible integration interfaces to meet many company-specific challenges. In contrast to predefined solutions, all parameters can be freely defined via a WCS. This means that the processes can be adapted to the customer's requirements and wishes. As described above, the following areas must be considered during integration: Processes (onboarding, migration and offboarding); Employees (organization and enablement); Master Data Management; and Technology (IT infrastructure and interfaces). This holistic approach also came into play in a project with DAW.

Europe's largest private manufacturer of building paints and thermal insulation introduced AutoStore at its headquarters in Ober-Ramstadt to optimize material flow and increase efficiency. However, it was only through direct integration into the existing SAP EWM system that AutoStore unfolded its full potential. One of the guarantees of success was the upstream analysis of the current situation at DAW. This guaranteed a customized connection via task interface with SAP EWM as the leading system. DAW thus benefits, among other things, from complete transparency in SAP EWM, from consistent system-guided work and from UI5 workplace dialogs.

Due to the direct connection of Auto-Store to SAP EWM with the known interfaces, no separate interface for the master data is necessary. This enables complete transparency of the inventories. The fact that no master data is transferred reduces the organizational effort in ongoing operations. This also eliminates the need for synchronization. This enables end-to-end transparency without additional effort for master data maintenance and the maintenance of an additional subordinate system. In addition, the user can use the standard EWM monitoring tools and all integrated automatic trades to monitor and, if necessary, control them.

Resource management integrated in SAP EWM can be used for resource planning and work organization through seamless integration analogous to the other trades in the warehouse. For example, the control or assignment of different "worklists" to personnel resources can be controlled via standard tools. The storage and retrieval strategy defined in EWM can also be viewed transparently at any time.

In addition, a direct integration of the AutoStore enables the use of the so-called slotting function of the EWM system across all trades. This is a strategy for placing stock in different locations in the warehouse in order to optimize the productivity of processes such as goods receiving, replenishment or picking. In this way, the warehouse space can be optimally utilized and, based on the physical parameters of the products, it can be determined for which products it is worthwhile for them to be stored in the AutoStore. For this purpose, in addition to the product parameters and the per se fast picking, the effort required for storage in the AutoStore must also be taken into account. The total effort decides on the optimal place in the warehouse.

The WMS optimum with SAP EWM

Which automation solution is ultimately the right one always depends on the individual requirements of the company, its products, the processes required and the space available, as well as other factors. In order to exploit the full potential of an automation solution, all the pieces of the puzzle should be included in the consideration at an early stage in the sense of a holistic supply chain architecture. The solution must therefore also take into account the processes, people and workstations as well as the existing IT infrastructure and master data. In any case, with SAP EWM, users have a future-proof WMS that can be expanded at any time, even for complex automated processes. The software implementation partner should have appropriate supply chain and logistics experience to integrate the automated trades as efficiently as possible. Smart system architectures and standard interfaces save licensing and maintenance costs here.